2.11

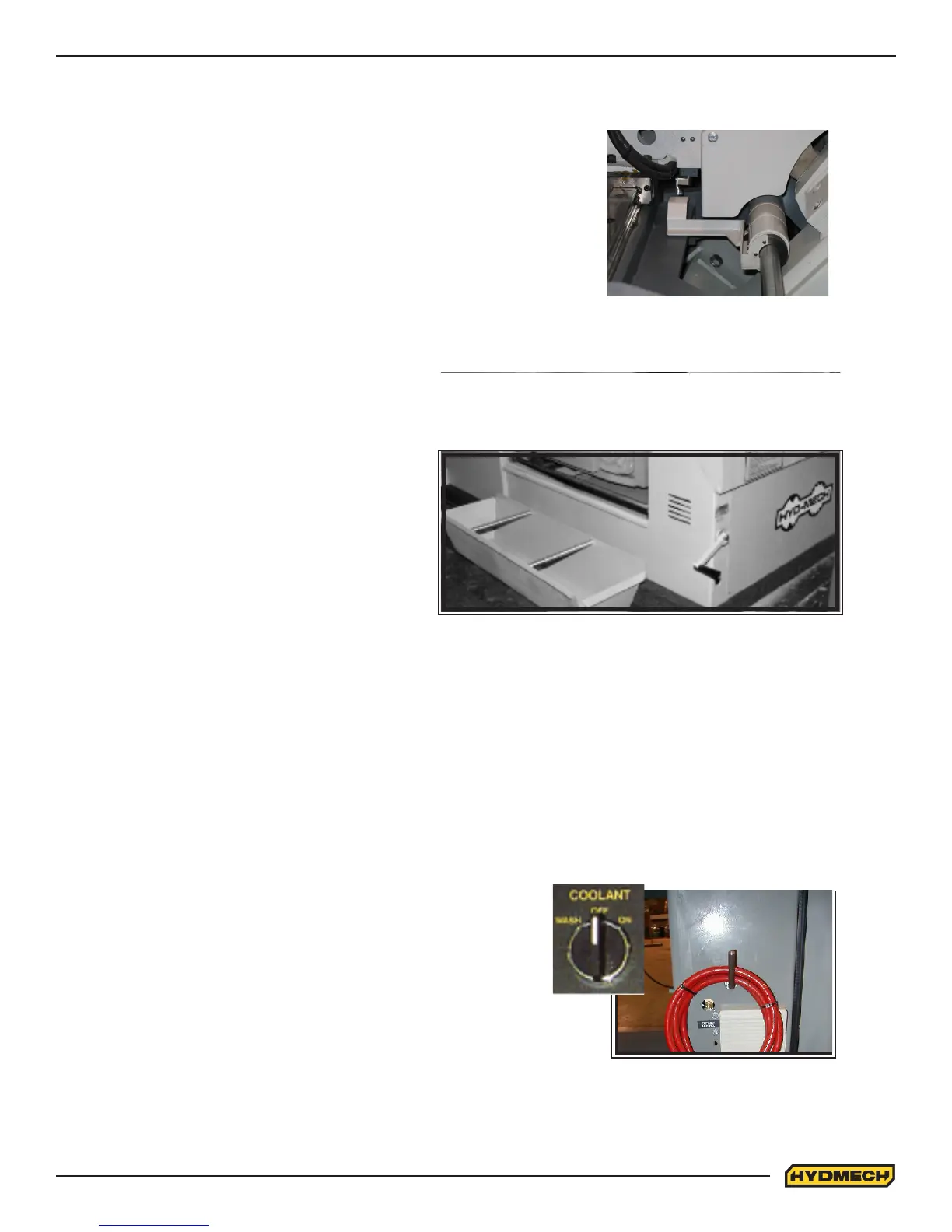

COOLANT FLOW

A generous ow of coolant should be applied in order to increase pro-

duction and blade life. The machine is provided with a control switch

on the operator panel and an independently controlled coolant spout.

This spout should always ood the blade with coolant. Slight adjust-

ment may be required when changing the blade speed. A properly

adjusted ow of coolant should cover the blade which in turn will carry

it into the cutting area. A ow adjusting tap is shown on the Console

side in the photo.

NOTE: When cutting materials that do not need coolant (cast iron)

some coolant ow is required to provide blade lubrication in order to

prevent blade scoring by the carbides.

HYDRAULIC CHIP CONVEYOR (optional)

An option available with the V18 is the hydraulic chip conveyor drive which provides an easier means of clean-

ing out the chips that accumulate while cutting. A Chip Conveyor control switch for the hydraulically driven chip

conveyor is located on the operator control panel.

CHIP CONVEYOR (optional)

The chips generated while sawing can be removed

from the bottom of the machine with the help of the

optional chip conveyor. Rotation of the chip convey-

or crank will operate the conveyor in the direction of

rotation of the crank. A chip bucket is included with

the chip conveyor option. The crank handle and chip

bucket are shown here.

Manual chip conveyor handle and chip bucket.

MECHANICAL CONTROLS

Coolant adjusting tap and

wash hose

HEAD FORWARD LIMIT SETTING

The Head Forward Limit is factory set and under normal operating conditions

should not need to be reset.

TO SET LIMIT:

If adjustment of the Shaft Collar is necessary, the Head Forward Limit is an

assembly on the vise cylinder rod. Loosen the set screw that allows setting

of the limit switch actuator, and adjust according to your needs. The photo

shows the Head Forward limit switch assembly. This assembly will be on

the same side of the head as the in-feed conveyor.

Head forward limit switch

Loading...

Loading...