HyPrecision 50S/60S/75S Operator Manual 808690 125

5 – Preventive maintenance

Preventive maintenance

1. Put O-ring lubricant on the O-rings. Put the O-rings on the check valve.

2. Use a cotton-tipped applicator to put high-pressure antiseize lubricant in the recess in the bottom of the

check valve.

3. Use a cotton-tipped applicator to guide the high-pressure poppet seat into the check valve. The wide end of

the poppet seat faces toward the check valve.

4. Push the poppet seat into the high-pressure antiseize lubricant in the check valve.

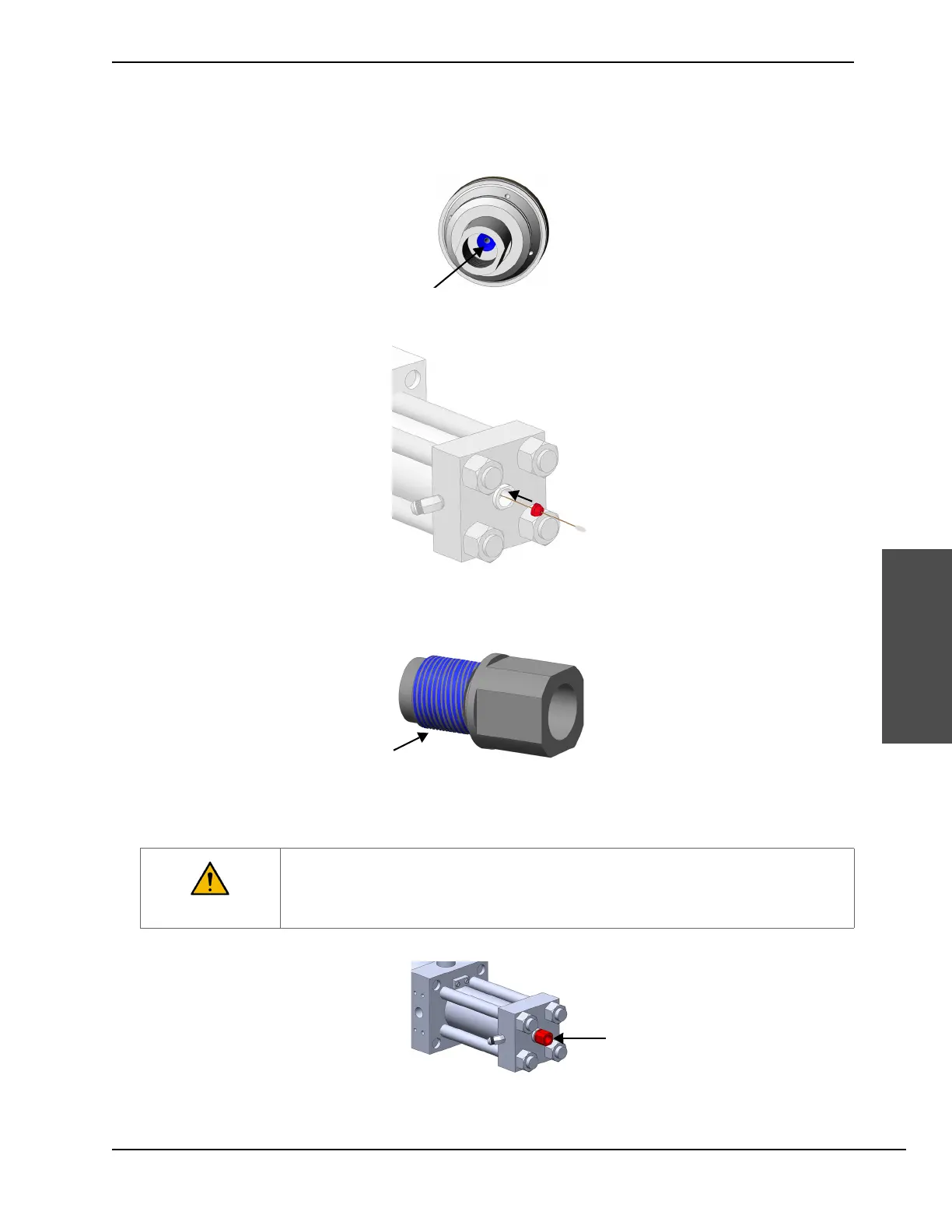

5. Put high-pressure antiseize lubricant on the threads of the output adapter.

6. Put the high-pressure poppet spring and the high-pressure poppet in the output adapter.

7. Put the output adapter in the check valve and tighten it by hand.

8. Torque the output adapter to 41 N∙m to 47 N∙m (30 lbf∙ft to 35 lbf∙ft).

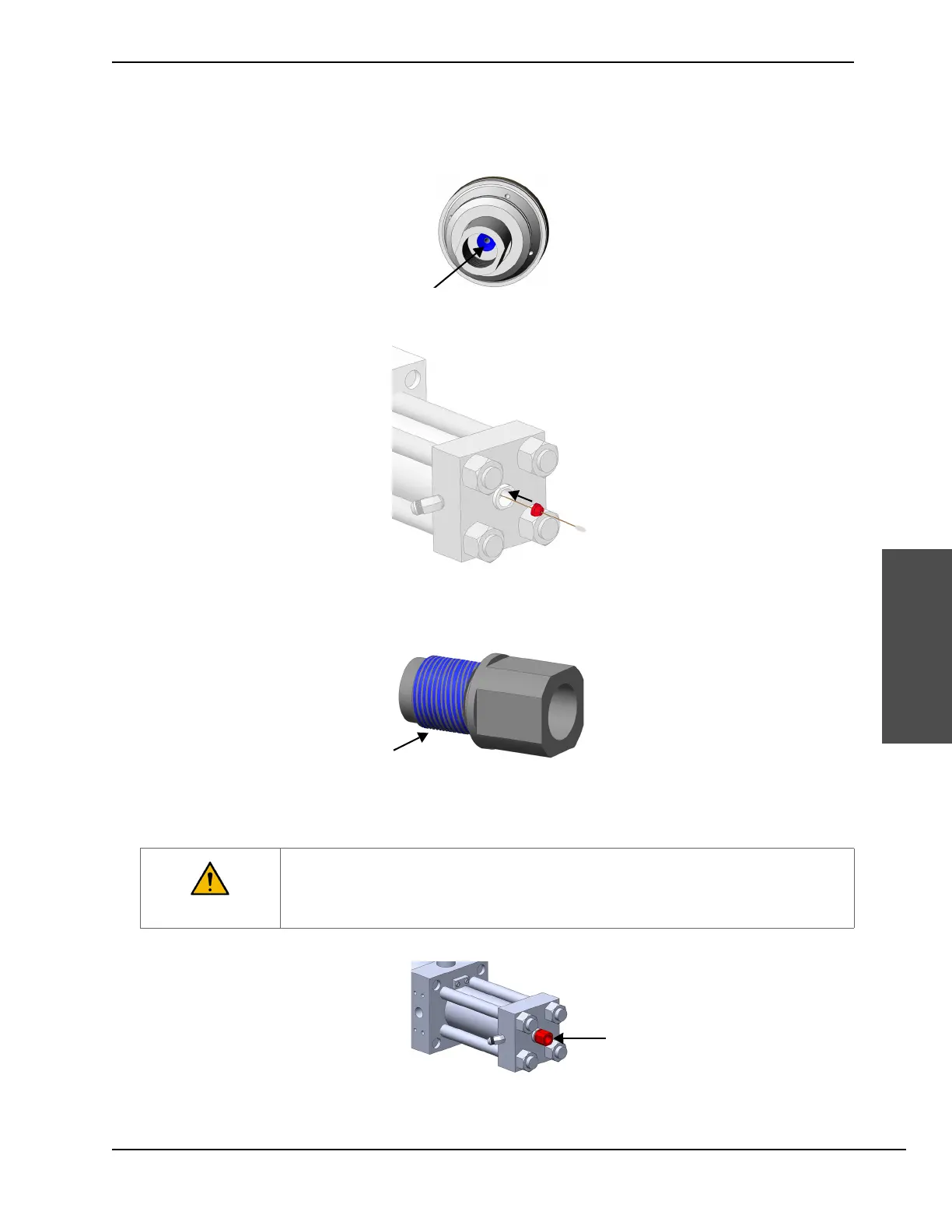

CAUTION

Tightening the output adapter with the poppet in an incorrect position can cause damage.

When the output adapter is properly installed, the gap between the wide part of the output

adapter and the check valve is 10 mm (3/8 inch) and no threads are visible. If the gap is larger

or threads are visible, make sure that the poppet parts have not moved.

Loading...

Loading...