HyPrecision 50S/60S/75S Operator Manual 808690 47

4 – Operation

Operation

Inspect the equipment before operation

Examine the equipment before starting the equipment.

Look for leaks, deterioration, damage, or other conditions that can interfere with operation.

Make sure that all connections and fasteners are tight, including locking devices, bolts, hoses, and fittings.

Make sure that all operational and instructional marks are present and legible.

Look at the sight gauge on the hydraulic fluid tank. If necessary, add hydraulic fluid.

Make sure that the water to the pump is turned on.

Make sure that the electrical main is turned on.

Make sure that the primary breaker disconnect lever on the electrical enclosure door is set to ON.

If the equipment was turned off because of a fault, correct the fault.

If the equipment was turned off because the EMERGENCY STOP button was pushed, reset the button on

the operation panel by turning it in the direction of the arrows (clockwise) until it pops out.

Turn on the pump

The primary motor drives a primary hydraulic pump that moves hydraulic fluid through the intensifier and a gear

pump that moves hydraulic fluid through the cooling loop. In this section, “pump on” means that the primary motor

is running and the pumps are on. “Pump off” means that the motor and the pumps are off.

Turn on the pump locally

The operator interface is the primary point of control.

1. Push the CONTROLS ON button to turn ON the control circuit inside the pump.

The pump can not be turned on until the control circuit is on.

2. Turn the cut-pressure control knob anticlockwise until it stops. This extends the life of the high-pressure seals

and other high-pressure parts.

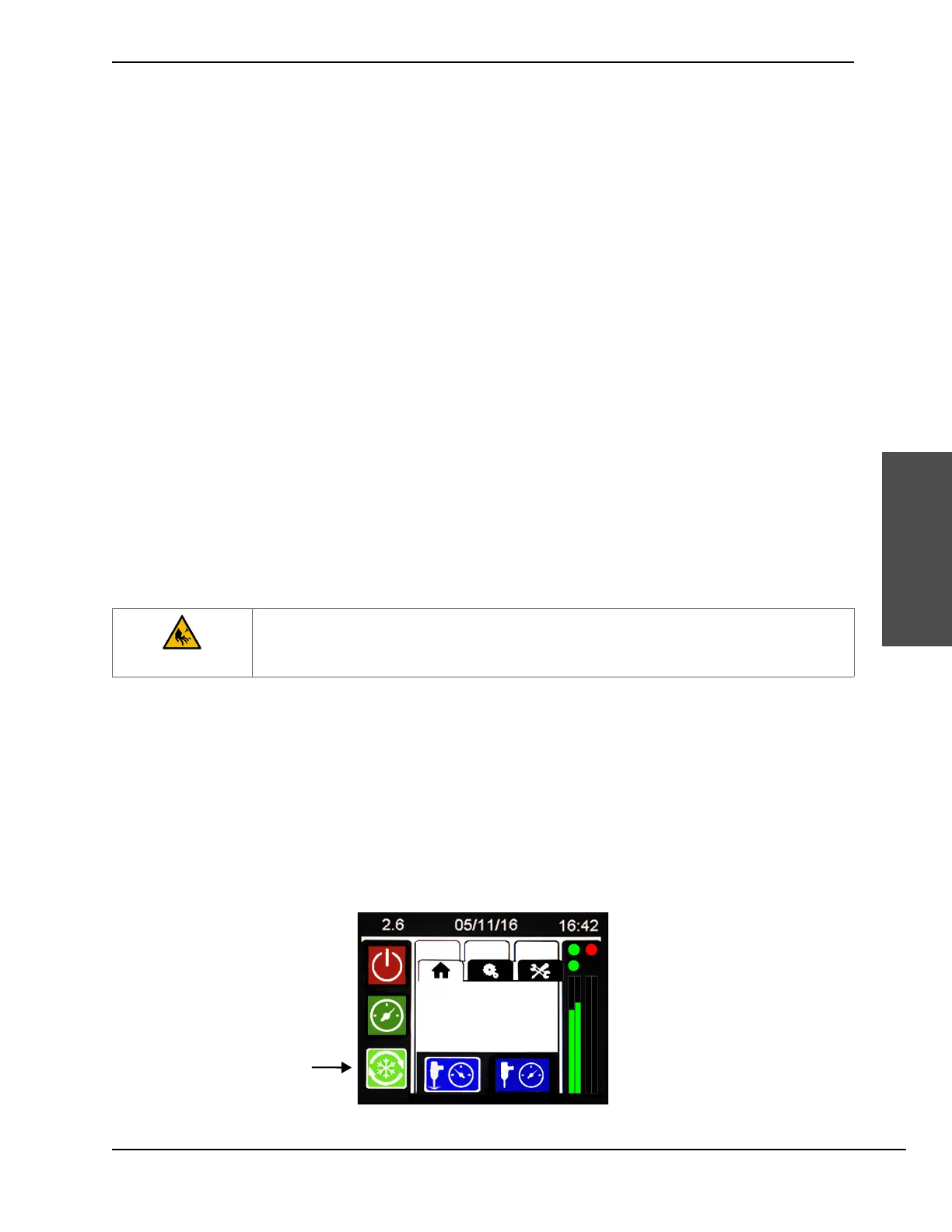

3. Touch the symbol on the operator interface to turn ON the pump in cooling mode. Pressure in the system

increases until it reaches the setpoint.

WARNING

Do not leave waterjet cutting equipment turned on and unattended.

Loading...

Loading...