196 HyPrecision 50S/60S/75S Operator Manual 808690

9 – Installation

Installation

Add hydraulic fluid

Some pumps are shipped without hydraulic fluid. Make sure that hydraulic fluid is available during installation and

startup. Refer to

Add hydraulic fluid on page 78 for instructions.

Connect the electrical power

The voltage, frequency, full load amperes, overload settings, and wire sizes differ depending on the pump size.

Pumps equipped for certain foreign electrical power can have different connection requirements. For

connection information, refer to the system schematic drawing.

Some pump models have a knockout at the bottom of the electrical enclosure for routing electricity into the

enclosure.

Power requirements are found on the data plate on the back of the pump and on the inside of the electrical

enclosure door.

1. Connect the electrical supply to the primary circuit breaker. This breaker is identified on the technical drawing

and inside the electrical enclosure as MAIN C.B.

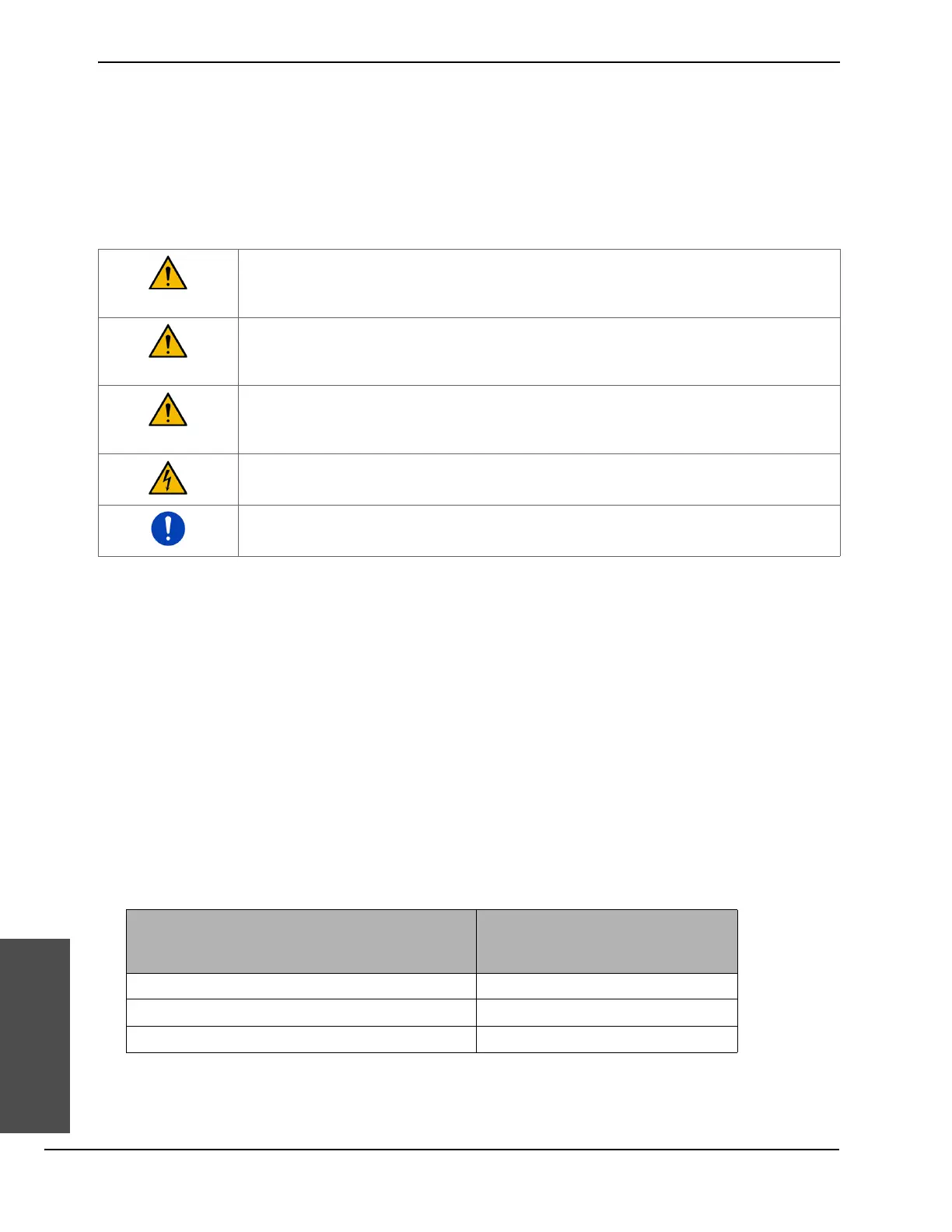

2. Attach a ground leg to the grounding lug inside the electrical enclosure. Use this table to find the minimum

cross-sectional area of the external copper ground leg.

HyPrecision pumps can leak up to 160 mA. To reduce the effects of a high leakage current, connect the

pump to a dedicated supply transformer that has separate windings.

WARNING

A line disconnect switch for incoming electrical power must be installed near the power supply to

serve as a supply-voltage disconnecting (isolating) device.

WARNING

The primary incoming electrical power must be installed by a licensed electrician and must be in

compliance with all applicable codes.

CAUTION

The primary feed protection device (circuit breaker or fuse) must be sized to handle inrush and

steady-state current. Use a motor-start circuit breaker or an equivalent if time-delay high-inrush

fuses are not permitted by local or national codes.

When connecting electrical power to this equipment, it is the buyer's responsibility to investigate

and comply with all local codes.

Use electrical parts that are certified by national or local electrical codes.

If the cross-sectional area (S mm

2

) of the

copper phase conductors supplying the

equipment is

The minimum cross-sectional

area (S

p

mm

2

) is

equal to or more than 16 equal to S

more than 16 and less than or equal to 35 16

more than 35 S/2

Loading...

Loading...