HyPrecision 50S/60S/75S Operator Manual 808690 133

5 – Preventive maintenance

Preventive maintenance

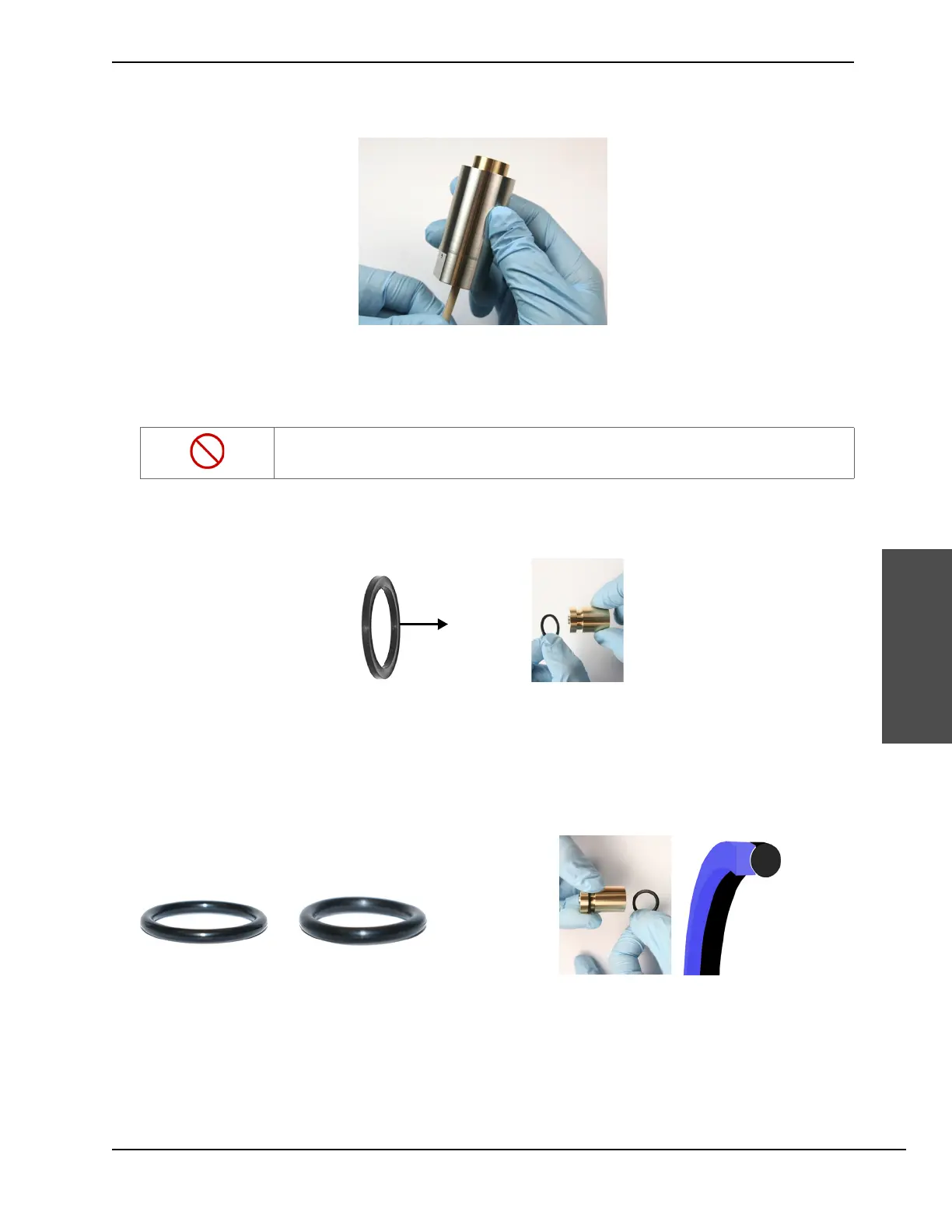

4. Use the wooden dowel from the bleed-down valve repair kit to push the hydraulic piston out of the actuator

housing.

5. Remove the piston O-ring and the piston O-ring backup from the hydraulic piston.

6. Clean the hydraulic piston with a lint-free towel and isopropyl alcohol. Examine the hydraulic piston for

deterioration, corrosion, or damage. Replace it if necessary.

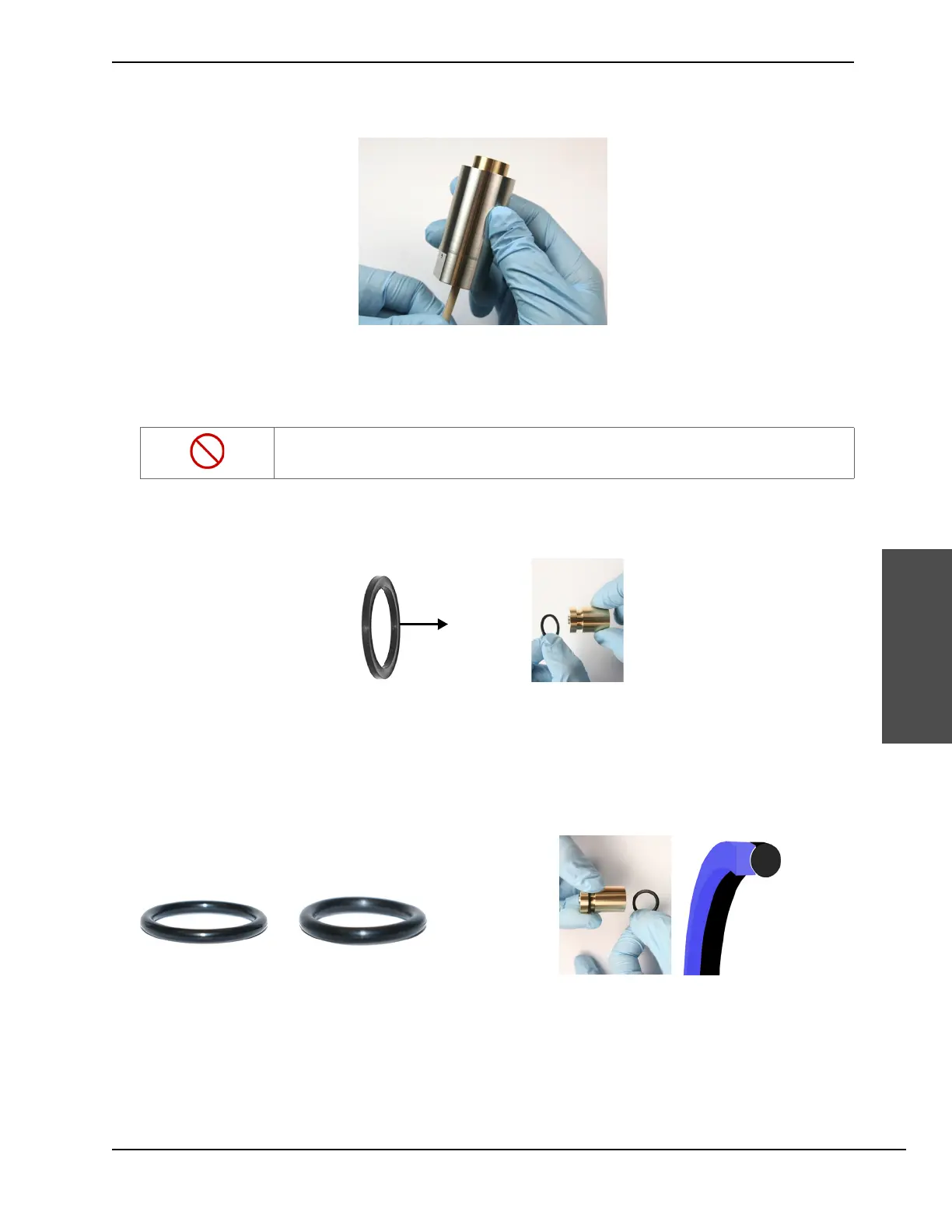

7. Put O-ring lubricant on the new piston O-ring backup. Roll the backup into the short end of the hydraulic

piston. The piston O-ring backup has a flat side and a concave side. Make sure the flat side of the piston

O-ring backup faces the short end of the hydraulic piston.

8. Put O-ring lubricant on the piston O-ring and roll it over the long end of the hydraulic piston. The piston

O-ring fits into the concave groove on the piston O-ring backup.

The SAE O-ring and the piston O-ring look almost the same. The SAE O-ring is thinner than the hydraulic

piston O-ring.

Do not use soap, detergent, or solvents.

Concave side

SAE O-ring Hydraulic piston O-ring

Loading...

Loading...