HyPrecision 50S/60S/75S Operator Manual 808690 169

7 – Troubleshooting

Troubleshooting

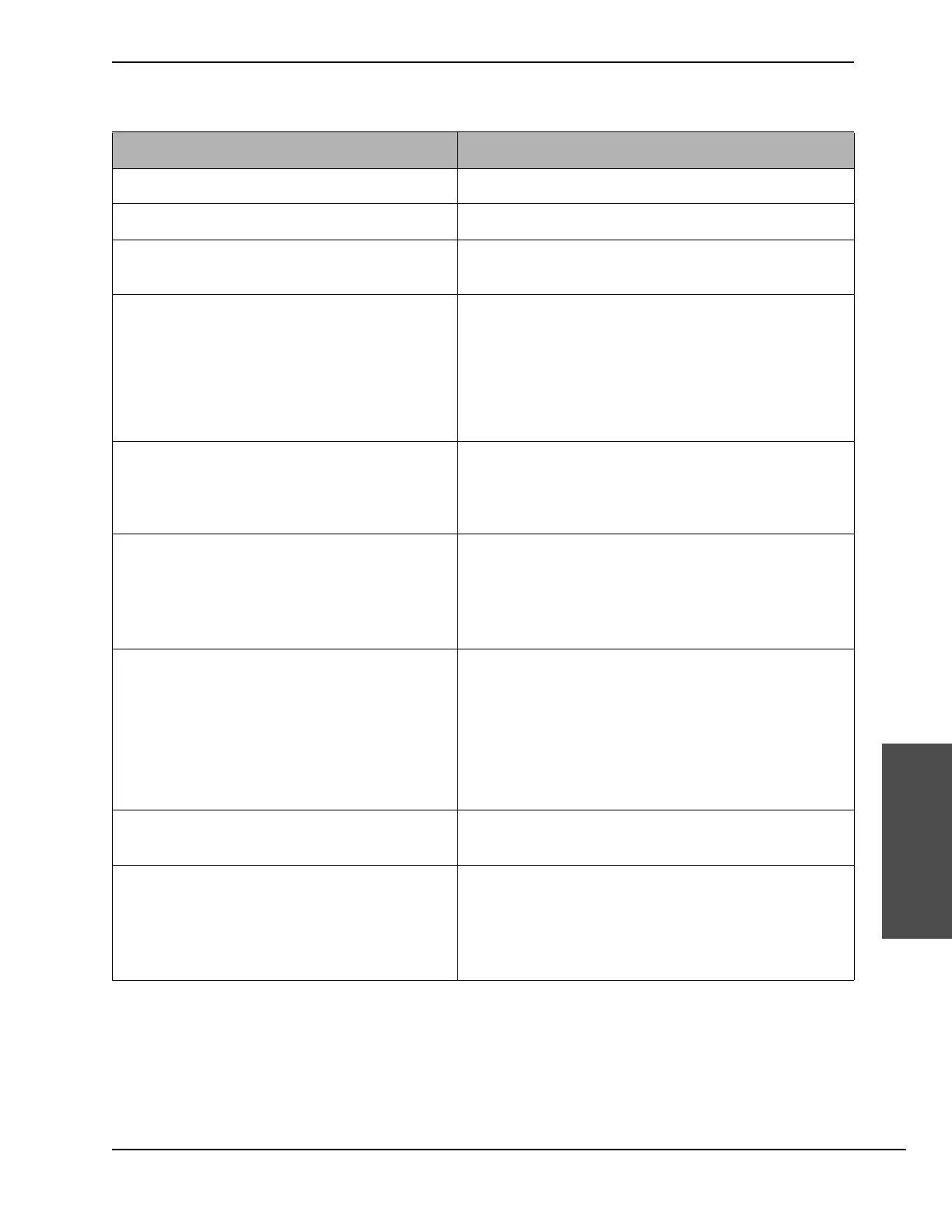

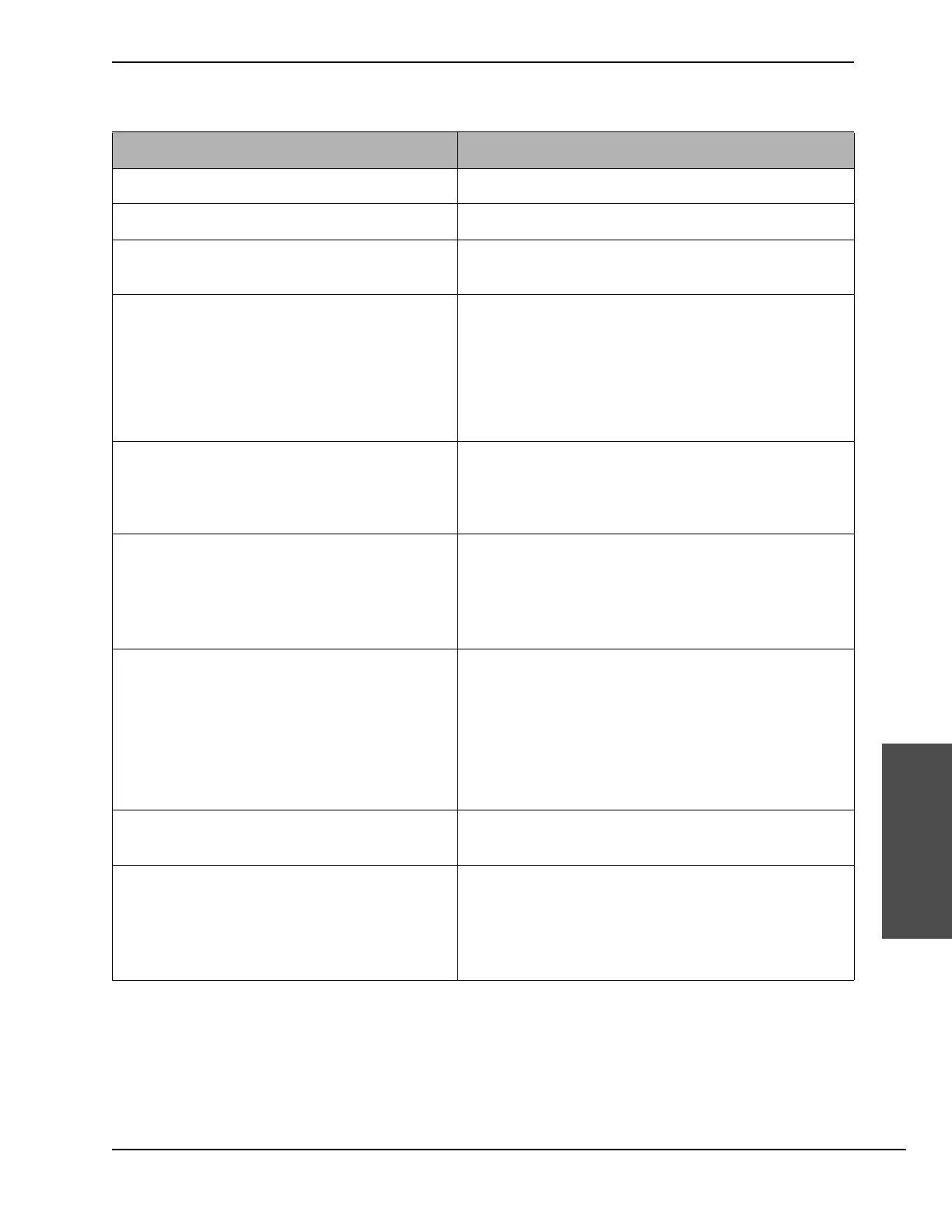

Possible cause Solution

The water is turned off. Make sure that the water to the pump is turned on.

The water valve is open. Make sure that the water valve is closed.

The boost pump bypass relief valve is not

adjusted properly.

Refer to

Adjust the boost pump pressure on page 201.

The boost pump has failed.

1. Open the water valve to drain the water from the

system. Make sure that the value on both

water-pressure gauges is 0.0 bar or 0 kPa (0 psi).

2. Examine the 10-micron water filter. If the filter is black,

the boost pump has failed and must be replaced.

Refer to page 91 for instructions.

The boost pump thermal overload (MS-BOOST/

OL-BOOST) has tripped.

1. Turn the knob clockwise to the

on position. When

released, the knob snaps anticlockwise to 0.

2. Turn the knob clockwise to the

on position.

Pressure is lost because of a leak.

• Identify the source of a leak and correct the problem.

Refer to

Leaks on page 163.

• If the intensifier strokes when it is in cut-pressure mode

with the cutting head turned off, check the bleed-down

valve and the high-pressure tubing for leaks.

A low-pressure poppet is sticking, worn, or

damaged.

• Examine the face of the poppet and the mating face on

the check valve. Make sure that the faces are smooth

and flat and have a nearly mirrored finish.

• Repair or replace the poppet.

• Make sure that the low-pressure poppet fits in the

basket without sticking.

• Repair or replace the check valve

A high-pressure poppet is sticking, worn, or

damaged.

Replace the high-pressure poppet, the spring, and the

seat.

The boost pump is not operating.

• Look through the bell housing to make sure that the

coupler is turning.

• In rare cases, the boost pump motor requires

replacement. Contact a Hypertherm Technical Service

Associate for assistance.

Loading...

Loading...