Powermax105 Operator Manual 6-15

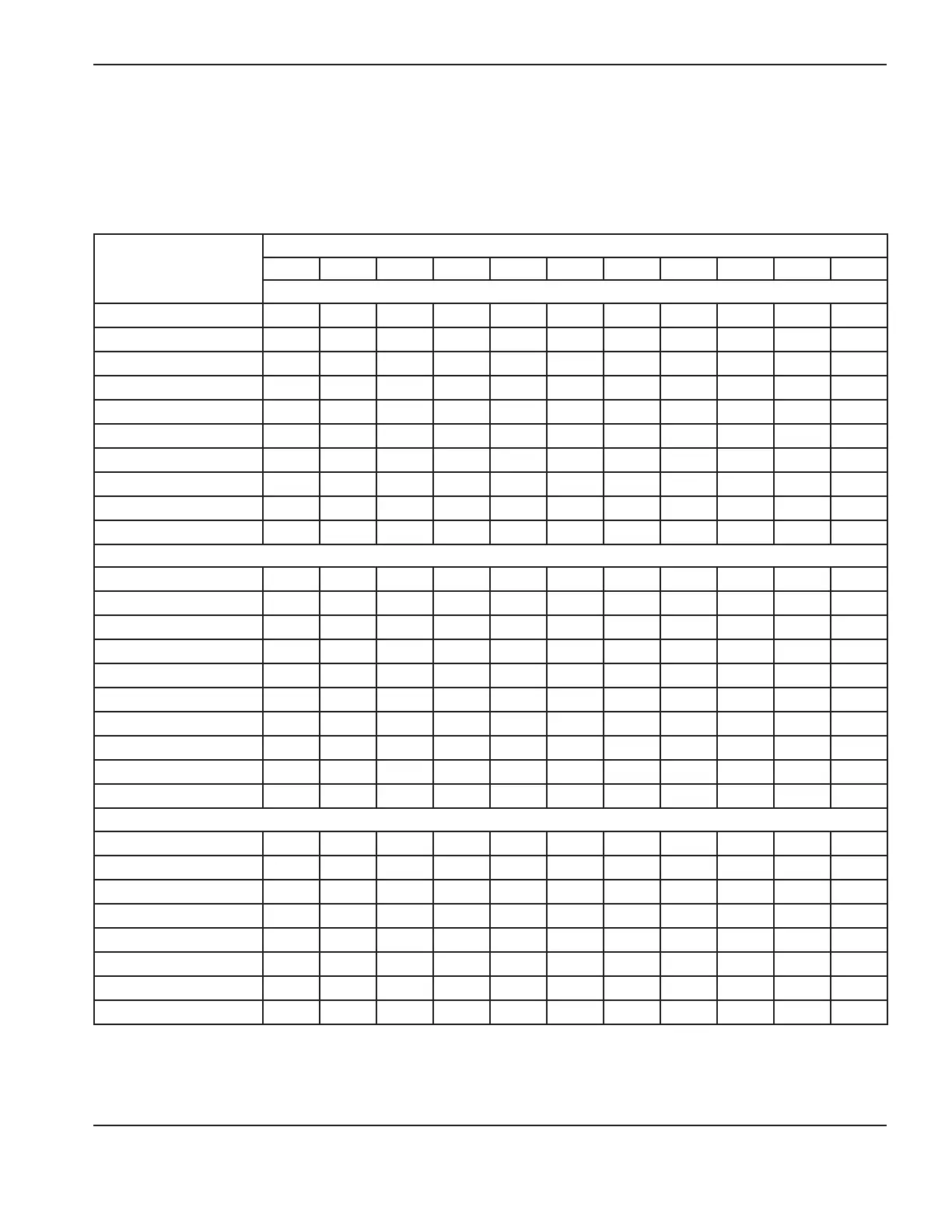

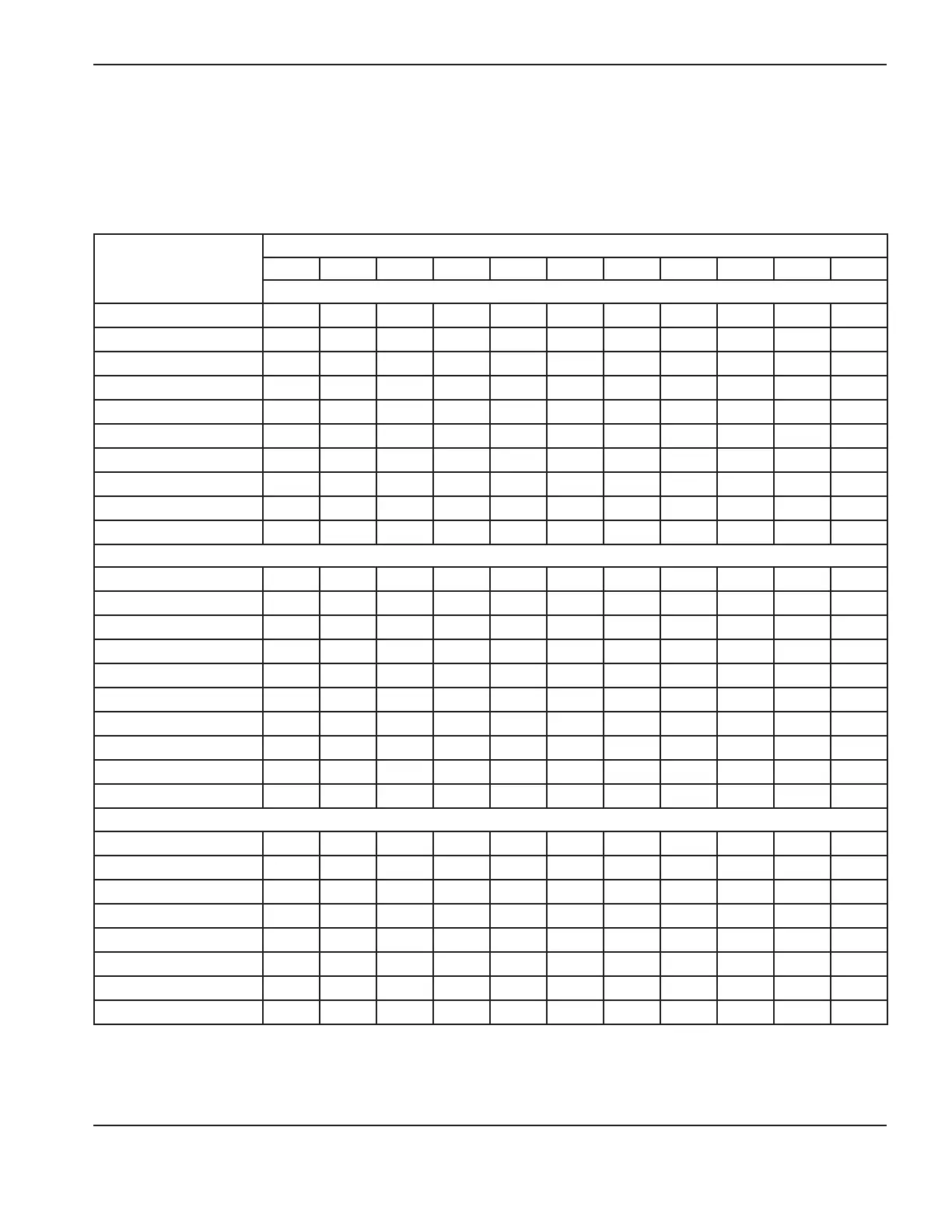

Estimated kerf-width compensation

The widths in the tables below are for reference. The data are obtained with the “Best Quality” settings. Differences

between installations and material composition may cause actual results to vary from those shown in the tables.

Estimated kerf-width compensation – Metric (mm)

Process

Thickness (mm)

0.5 1 2 3 6 8 10 12 16 20 25

Mild Steel

105 A Shielded 2.1 2.2 2.2 2.2 2.5 2.7 3.3

85 A Shielded 1.7 1.8 1.9 2.0 2.2 2.4 2.6

65 A Shielded 1.6 1.6 1.8 1.9 2.0 2.2 2.3

45 A Shielded 1.1 1.1 1.4 1.5 1.7

FineCut 0.9 0.7 0.5 0.6

Low Speed FineCut 0.6 0.7 0.7 0.6

105 A Unshielded 2.1 2.3 2.5 2.4 2.7 2.9 3.2

85 A Unshielded 1.7 1.8 1.9 2.0 2.1 2.1 2.3

65 A Unshielded 1.6 1.6 1.7 1.8 1.9 2.0

45 A Unshielded 0.5 0.9 1.3 1.3

Stainless Steel

105 A Shielded 1.9 2.1 2.3 2.3 2.3 2.6 2.9

85 A Shielded 1.6 1.8 1.9 2.1 2.3 2.4 2.5

65 A Shielded 1.4 1.5 1.8 1.9 2.0 2.2 2.4

45 A Shielded 0.9 1.1 1.5 1.6 1.8

FineCut 0.2 0.5 0.4 0.5

Low Speed FineCut 0.6 0.5 0.6 0.5

105 A Unshielded 2.0 2.2 2.4 2.5 2.7 2.7 3.1

85 A Unshielded 1.7 1.7 1.8 1.9 2.1 2.2 2.4

65 A Unshielded 1.6 1.6 1.8 1.8 1.9 2.0

45 A Unshielded 0.5 1.0 1.3 1.5 1.5

Aluminum

105 A Shielded 2.3 2.3 2.4 2.6 2.7 3.0 3.5

85 A Shielded 2.0 1.9 2.0 2.1 2.2 2.4 2.6

65 A Shielded 1.9 1.9 1.9 2.0 2.1 2.3 2.5

45 A Shielded 1.5 1.5 1.6 1.5

105 A Unshielded 2.2 2.4 2.5 2.6 2.7 3.0 3.3

85 A Unshielded 1.9 1.9 1.9 2.0 2.0 2.1 2.2

65 A Unshielded 1.8 1.8 1.8 1.8 1.9 2.0

45 A Unshielded 1.6 1.5 1.4 1.5

Loading...

Loading...