OPERATION

3

powermax1650 Operator Manual 4-19

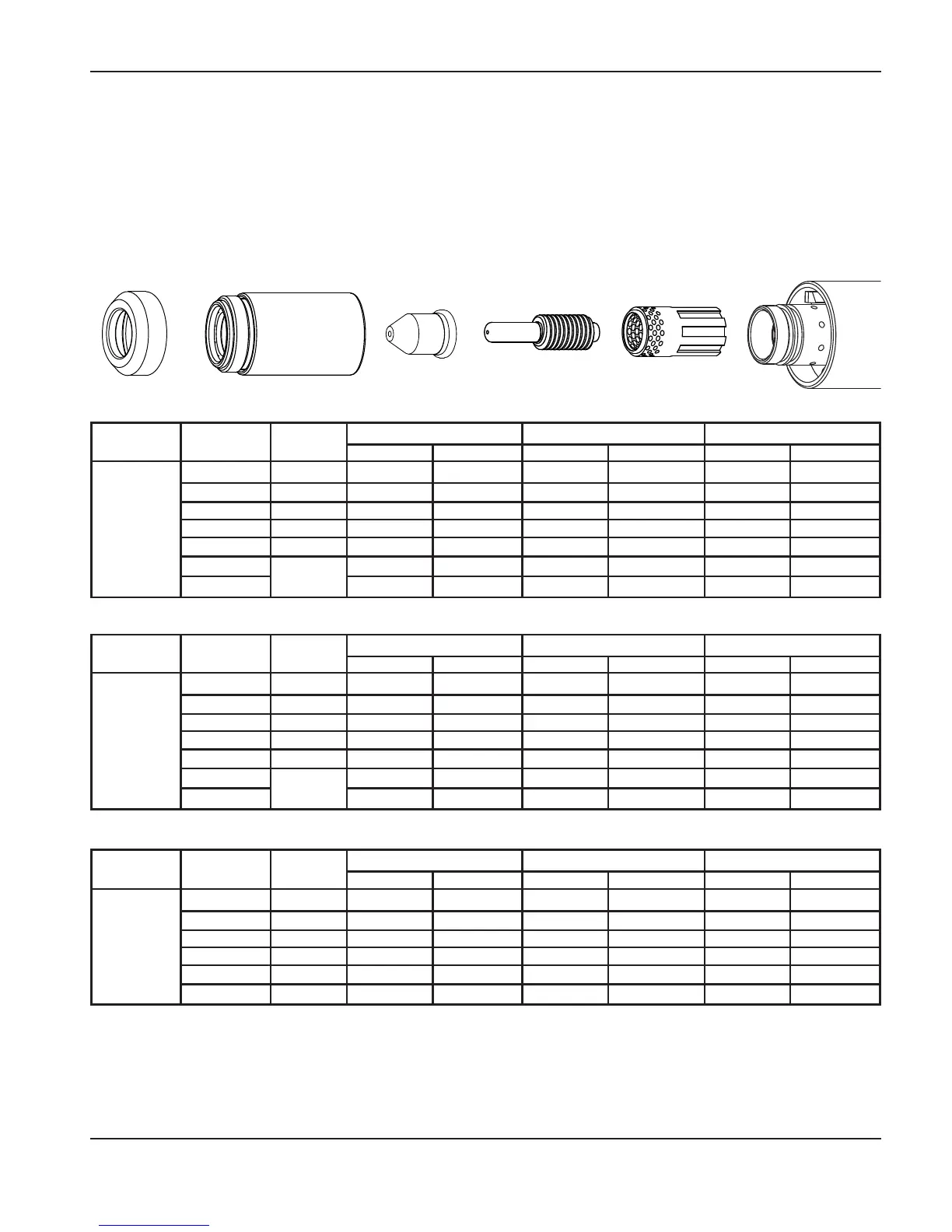

100 amp mechanized unshielded consumables

• Torch-to-work dis tance for the following cut chart is 3/16 in (4.8 mm) for all cuts.

Retaining cap

220048

Nozzle

220064

Electrode

220037

Swirl ring

220051

T100M-2

torch

Deflector

120979

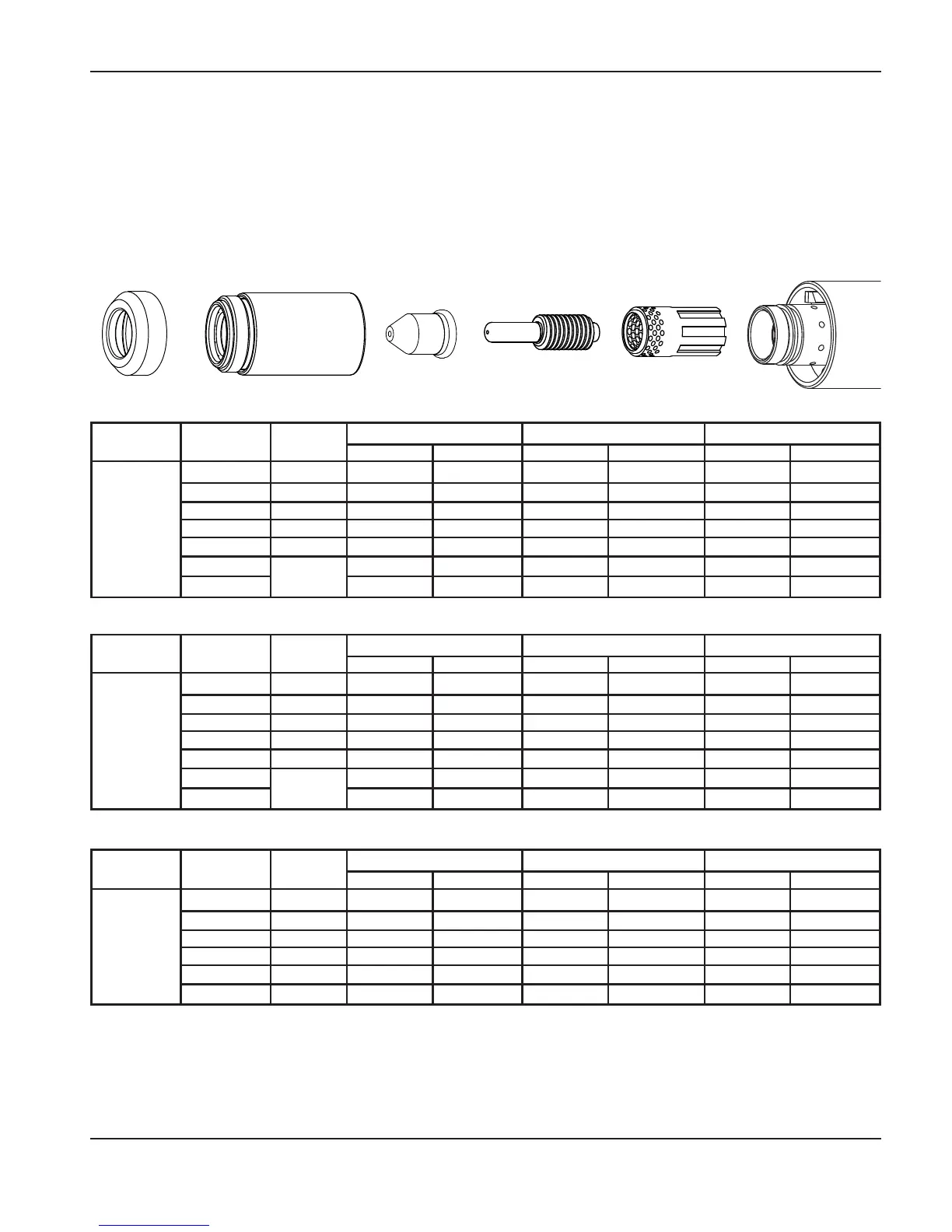

Maximum travel speeds are the fastest speeds possible for cutting the material without regard to cut quality. Optimum travel

speeds provide the best cut angle, least dross and best cut surface finish. Remember that cut charts are intended to

provide a good starting point for each different cut assignment. Every cutting system requires “fine tuning” for each

cutting application in order to obtain the desired cut quality.

Arc current Arc voltage

Pierce

delay

Material thickness

Maximum travel speed Optimum travel speed

Inches mm

IPM mm/min IPM mm/min

100

136 0.5

1/4” 6.4

210 5334 137 3479

139 0.5

3/8” 9.5

122 3098 79 2006

142 1.0

1/2” 12.7

91 2311 59 1498

146 1.0

5/8” 15.9

57 1447 37 939

150 1.5

3/4” 19.0

43 1092 28 711

155

NA

1” 25.4

26 660 17 431

160

1 1/4” 31.8

16 406 10 254

Arc current Arc voltage

Pierce

delay

Material thickness

Maximum travel speed Optimum travel speed

Inches mm

IPM mm/min IPM mm/min

100

137 0.5

1/4” 6.4

255 6477 166 4216

139 0.5

3/8” 9.5

153 3886 99 2514

142 1.0

1/2” 12.7

107 2717 70 1778

147 1.0

5/8” 15.9

77 1955 50 1270

150 1.5

3/4” 19.0

51 1295 33 838

154 NA

1” 25.4

31 787 20 508

Mild steel

Stainless steel

Aluminum

Arc current Arc voltage

Pierce

delay

Material thickness

Maximum travel speed Optimum travel speed

Inches mm

IPM mm/min IPM mm/min

100

136 0.5

1/4” 6.4

241 6121 157 3987

139 0.5

3/8” 9.5

131 3327 85 2159

142 1.0

1/2” 12.7

81 2057 53 1346

146 1.0

5/8” 15.9

51 1295 33 838

150 1.5

3/4” 19.0

33 838 22 558

155

NA

1” 25.4

22 558 14 355

161

1 1/4” 31.8

11 279 7 177

Loading...

Loading...