OPERATION

3

4-18 powermax1650 Operator Manual

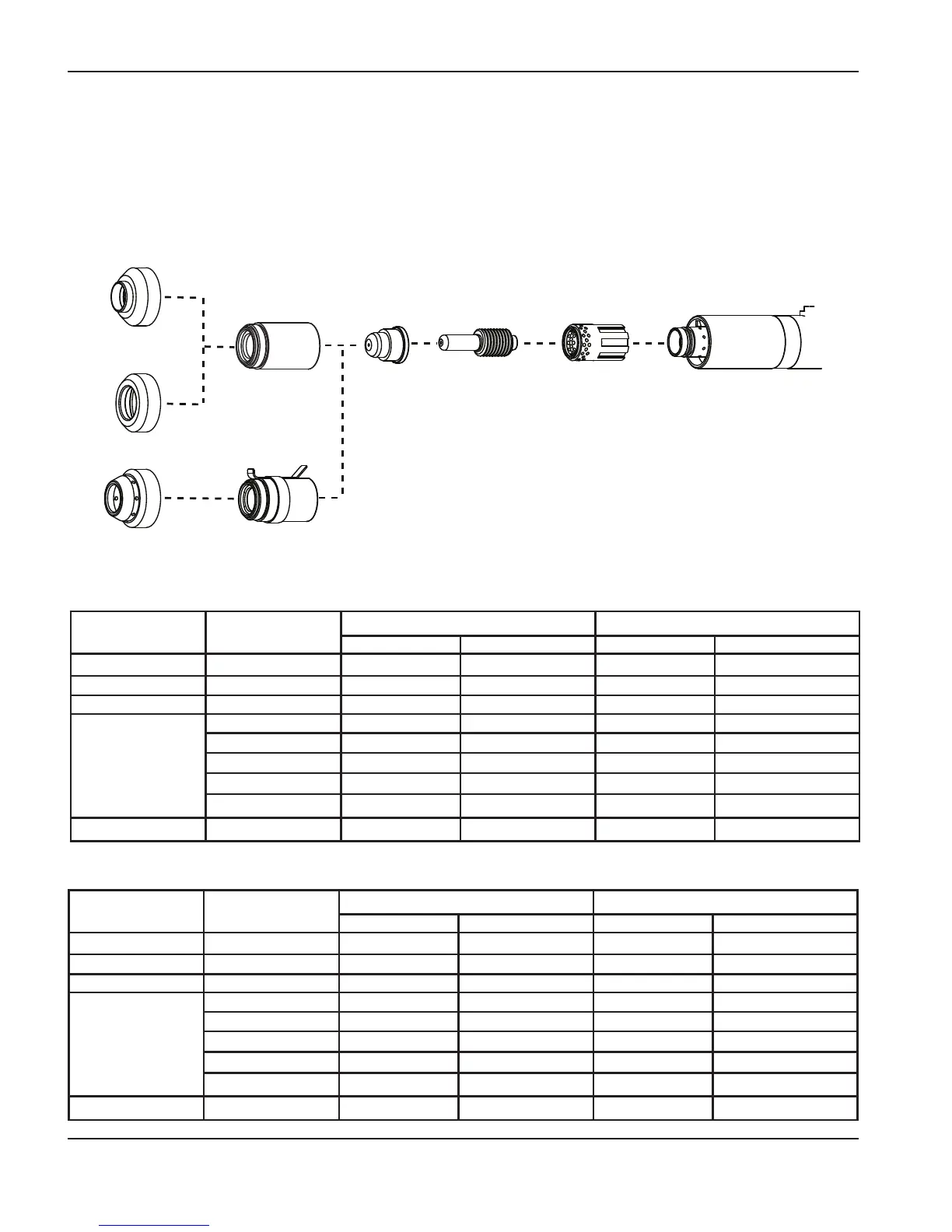

Arc current Arc voltage

Material thickness

Approximate travel speeds

Inches mm

IPM mm/min

50 76

10 Ga 3.4

90 2286

40 83

10 Ga 3.4

50 1270

45 77

12 Ga 2.7

120 3048

40

81

12 Ga 2.7

70 1778

79

14 Ga 1.9

135 3810

79

16 Ga 1.5

150 3810

79

18 Ga 1.2

150 2540

78

20 Ga 0.9

120 2540

30 80

24 Ga 0.6

150 3174

Mild steel

Arc current Arc voltage

Material thickness

Approximate travel speeds

Inches mm

IPM mm/min

50 63

10 Ga 3.4

80 1905

40 73

10 Ga 3.4

60 1524

45 63

12 Ga 2.7

100 3174

40

72

12 Ga 2.7

80 1905

65

14 Ga 1.9

150 3810

64

16 Ga 1.5

150 3810

64

18 Ga 1.2

150 3810

65

20 Ga 0.9

150 3810

30 66

24 Ga 0.6

150 3810

Stainless steel

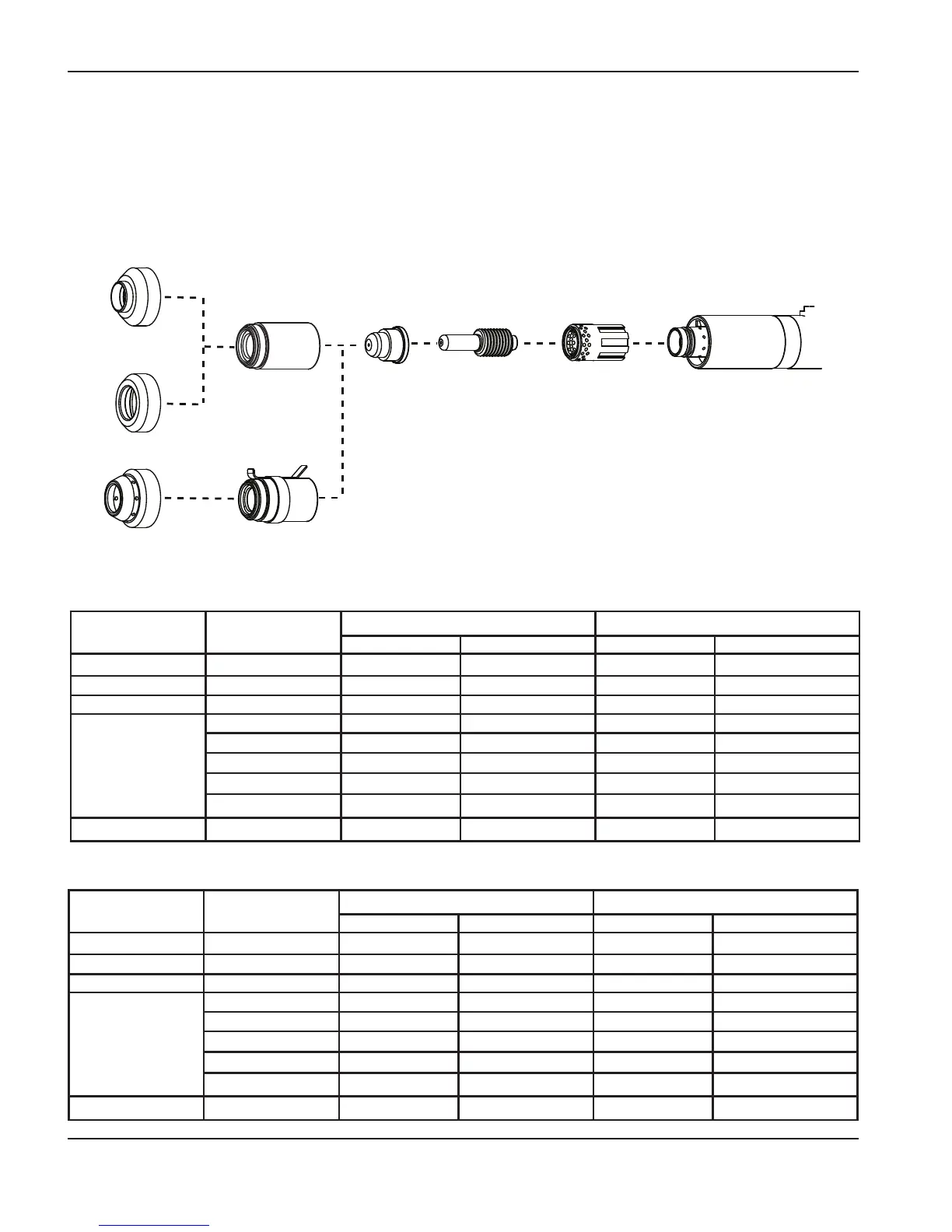

FineCut consumables

• Torch-to-work dis tance for the following cut chart is 0.08 inches (2 032 mm) for mild steel and

0.010 inches (0.254 mm) for stainless steel.

* For use with CE systems.

** Use an ohmic sensing cap when a compatible

torch height controller is installed.

120925120926

220329

120928

220061**

220325*

120979

220404

Deflector Retaining

cap

Nozzle Electrode Swirl ring T100M-2

torch

Loading...

Loading...