Hooks Replacement for Model 555 5000 SRM 969

7. Position hydraulic motor with key (23) and fasten

in place with four socket head screws.

8. Connect hydraulic lines and electrical connec-

tions.

Hooks Replacement for Model 555

INSPECT

WARNING

The lifting hooks are safety critical compo-

nents due to the fact that it is the hook that

carries all the load when picking up and carry-

ing a container. Hooks are a wearing part and

should be inspected for wear and or damage

on a regular basis.

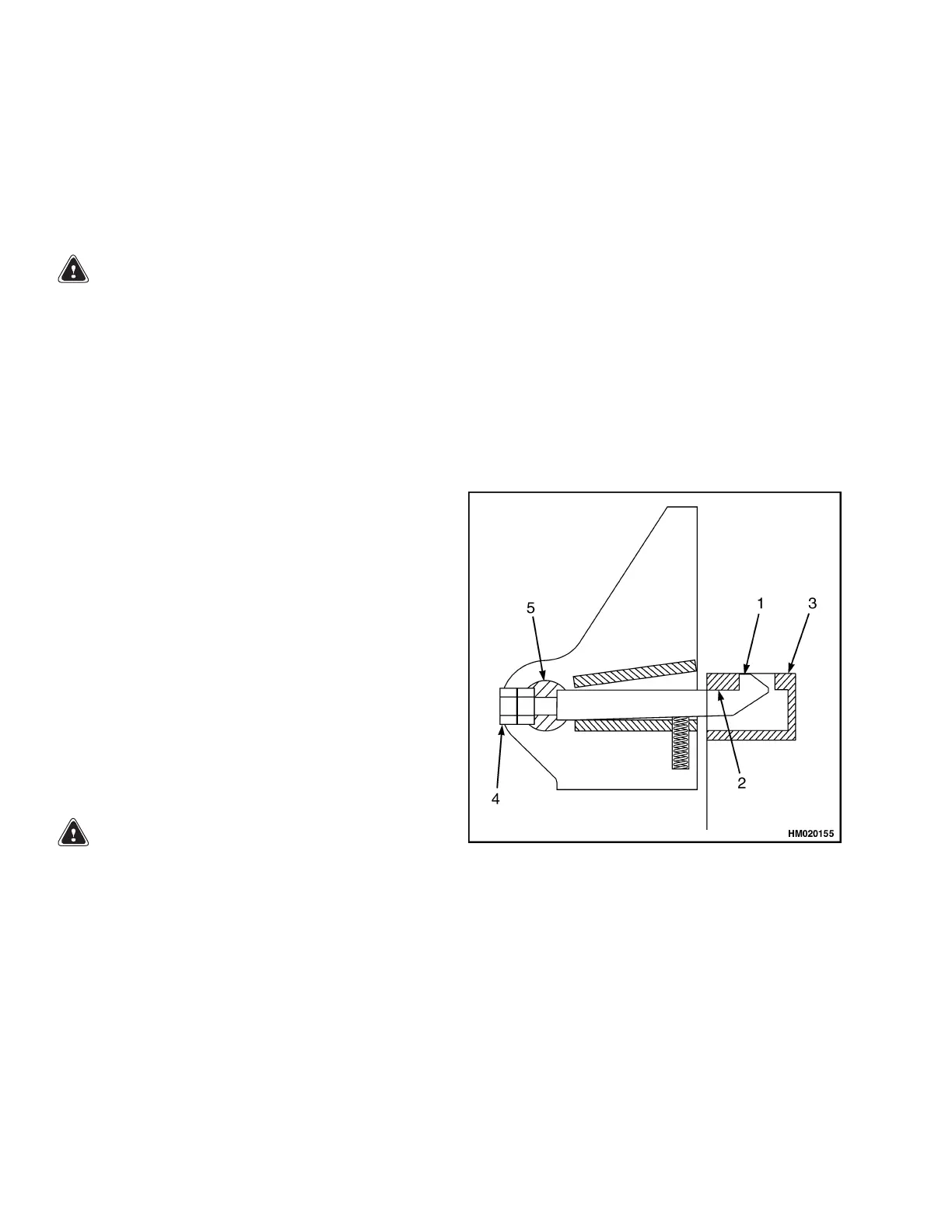

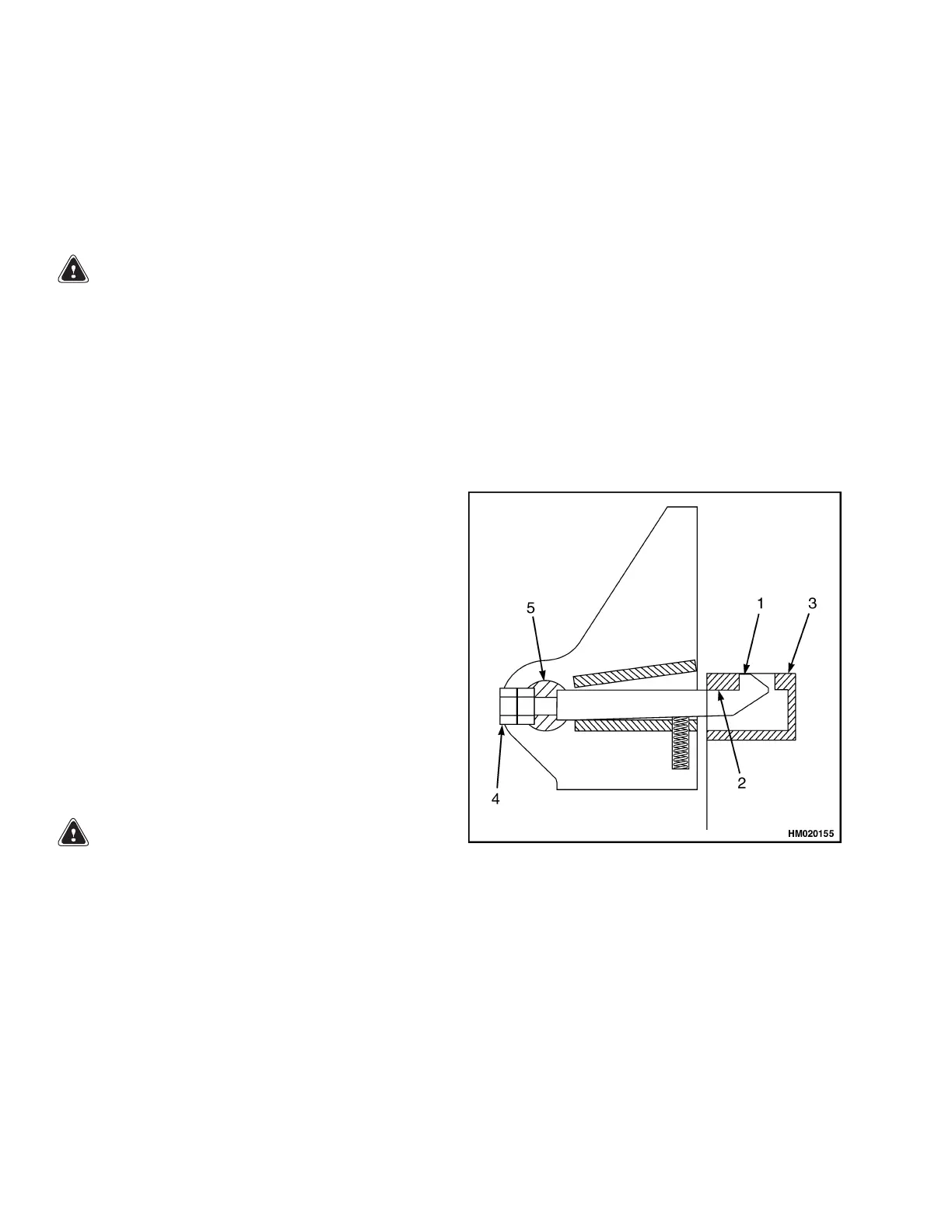

1. Check hook for cracks. Replace hook if damaged.

2. Check inside angle of hook. New hooks have

22 mm (0.87 in.) of material between flat por-

tion of hook and top of hook. The hook should

be replaced if worn area leaves less than 15 mm

(0.59 in.) from start of wear area to flat portion

of hook. See Figure 9 and Figure 10.

3. Check wear area of hook where corner casting

of container is carried. This area should be in-

spected and when wear is more than 5% of origi-

nal thickness, hook should be replaced. See Fig-

ure 9 and Figure 10.

4. Check tightness between nuts and threads of

hook. Hook should be replaced if threads of hook

become worn. See Figure 9.

5. The pin that hook is secured through can wear

andshouldbereplacedifexcessplayisdiscov-

ered.

WARNING

Do not try to correct hook alignment by bend-

ing. Replace damaged hooks.

6. A common fault that can be found is hooks get

bent sideways. If hook is bent more than 5 de-

grees, it should be replaced with a straight one.

REMOVE

1. Remove nut and washer that holds hook in place.

2. Remove defective hook.

3. Replace hook if necessary.

INSTALL

1. Install new hook.

2. Assemblenutandwashertoholdhookinplace.

3. Tighten nut to 110 N•m (81 lbf ft).

1. INSIDE ANGLE

2. WEAR AREA

3. CORNER CASTING

4. HOOK THREADS

5. PIN

Figure 9. Hook Inspection

16

Loading...

Loading...