Maintenance 5000 SRM 969

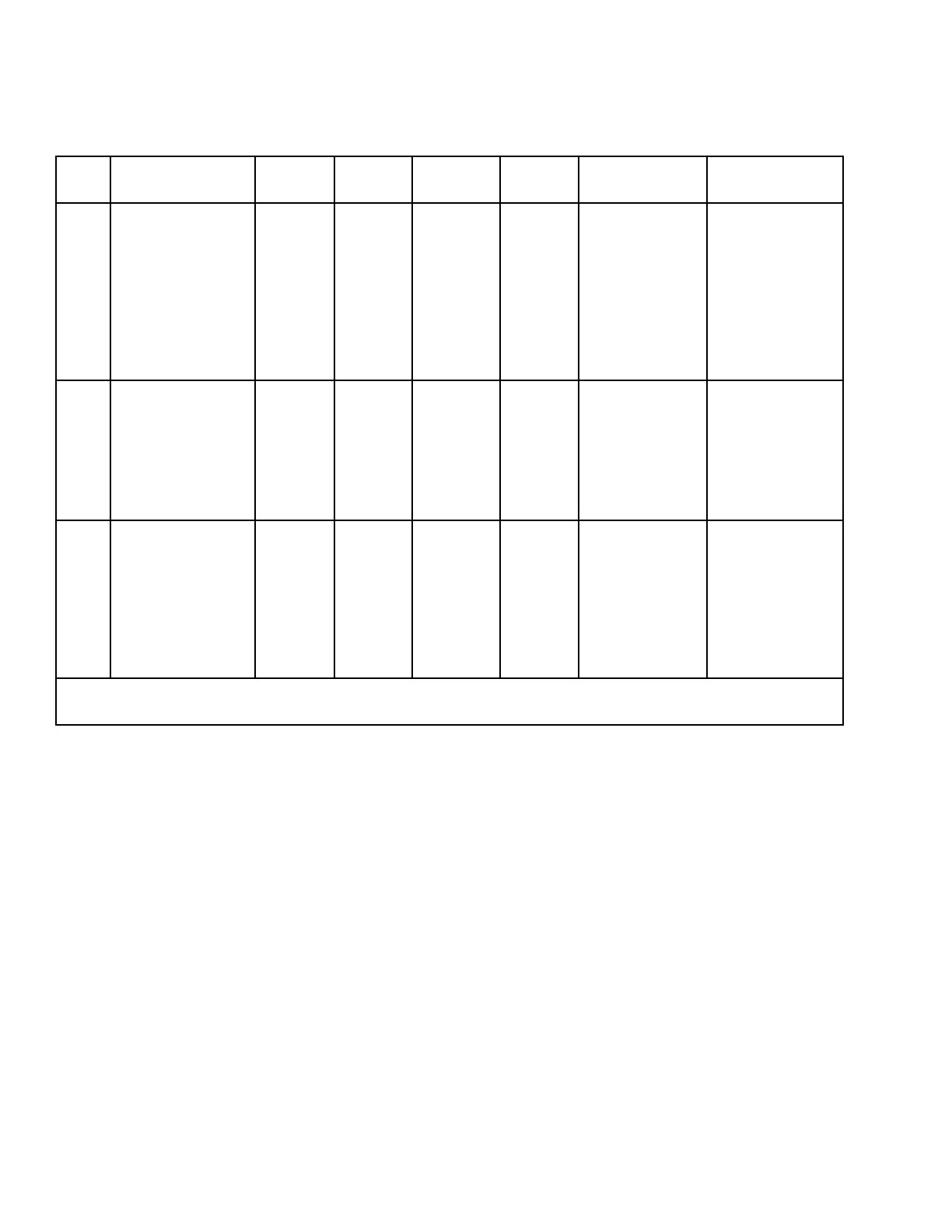

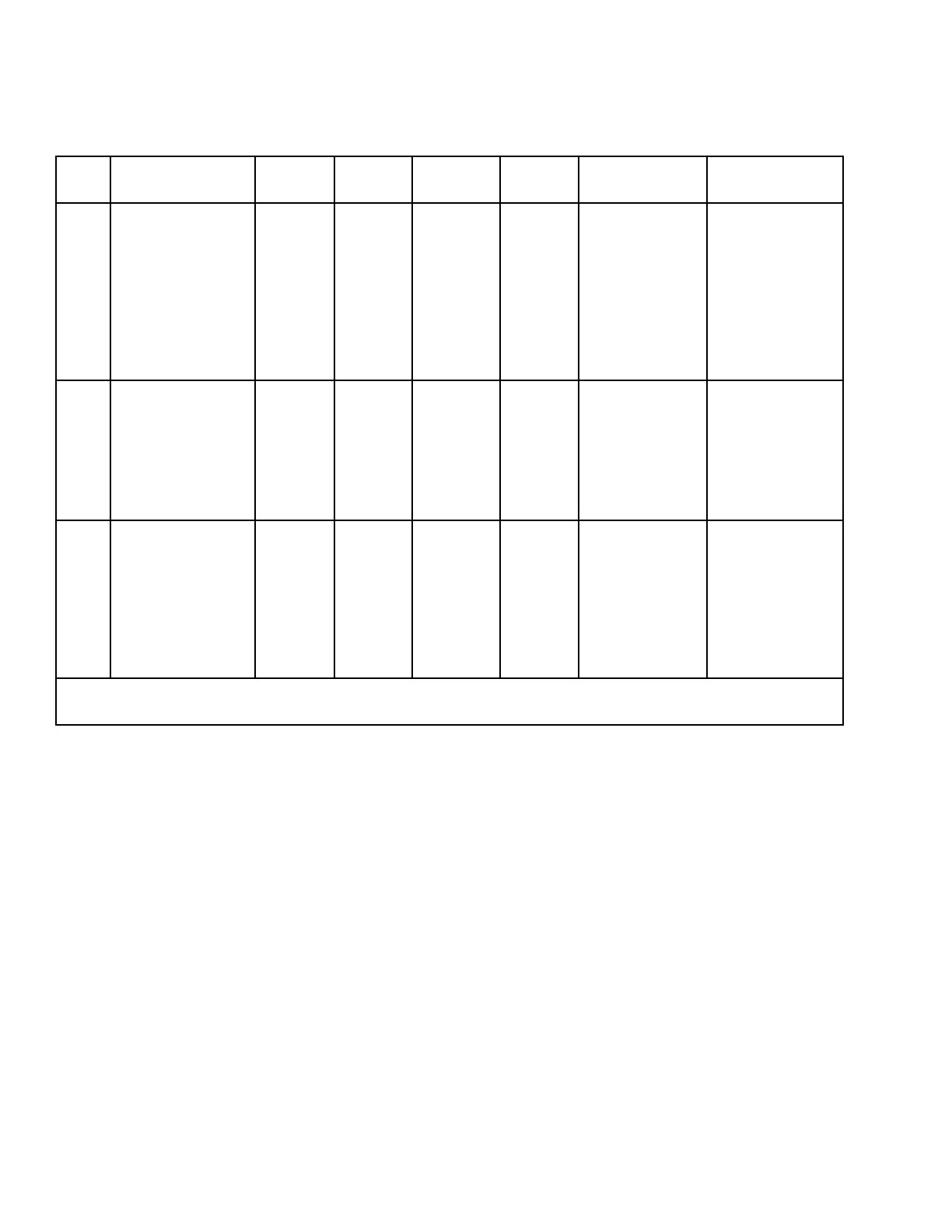

Table 2. Maintenance Schedule (Continued)

Item

No.

Item

250 Hr/

1Mo

500 Hr/

3Mo

1000 Hr/

6Mo

2000 Hr/

1Yr

Procedure or

Quantity

Specification

4

Twist Lock

Assemblies

Model 558

XL Check for wear

and possible

damage of twist

lock and twist

lock sleeve.

Replace if in

doubt.

Lubricate four

fittings.

Multipurpose

Grease

1

5

Lower Sideshift

Slider Pads

X Check for wear of

nylon pads and

replace before

metal-to-metal

contact between

carriage and

frame occurs.

6

End Beam Slider

Pads

X Check for wear of

nylon pads and

replace before

metal-to-metal

contact between

end beam and

extension beam

occurs.

X = Check C = Change L = Lubricate

1

Multipurpose grease with 2-4% molybdenum disulfide.

ADDITIONAL ATTACHMENT

MAINTENANCE

1. Inspect main attachment components for dam-

age, cracks, and distortion.

2. Inspect signal and control systems for correct op-

eration.

3. Check hydraulic pressures periodically.

4. Check all hydraulic cylinders for leaks and reseal

if necessary.

5. Inspect all hydraulic hoses for damage and leak-

age. Replace any damaged or leaking hoses.

24

Loading...

Loading...