+5

+4

+3

+2

+1

0

,'>-

I).

//-

')0.

IA

I).

I'-~

/L~

~~

ILl

/1

\

/L_\

/

/'L

_\

/ \

/ \

/

\

/ \ /

\

/

/

\

\ /

\

/ \ / \ /

\

\ /

/

1/

V

V v

.;

. ' ,

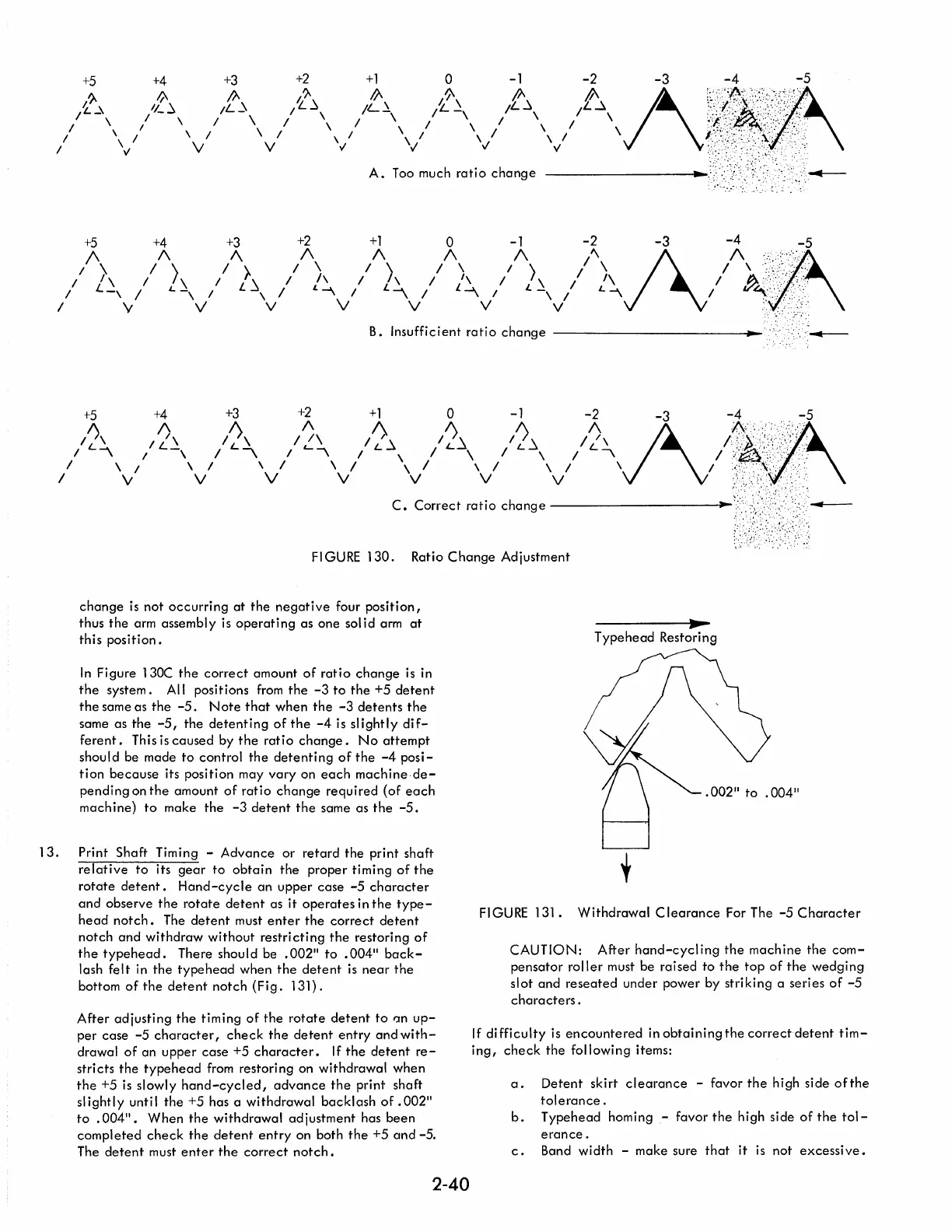

A.

Too

much

ratio

change

---------

..

~~.;::.

<

....

/:;.,

..

~.,

.....

:.:. ',-"

.:

~

-

..

>~

~

.

.

......

,<.-."

B. Insufficient

ratio

change

--------------i~~

..

'::.,'~

+5 +4 +3 +2

+ 1 0 -1

-2

-3

-4

-5

I)

A

I>

/\

'>

'>

I)

1\

A

I\:·.,:<~::.·i.::'.:·:·

/ L \ /

l~

I L \ I ,!.\ / L

~

/

L~

/ L

~

/

("

l

...

:

..

:.-::A.·

..

<>

..

'.'.';;

..

·.·

..

:::·.'

...

::::'.·;

..

:

.;:.'

/ \ / \ I

"\

/ \ I \ I \ I \ I ' / ::i!f?}'':;:::' .:'.

/ \ / \ I

,/

\ I \ I

,I

\

I'

/

>:::'.:'

:\'

.....

:.:

I

\!

V V V V V V

;.:'.';,,':-';;>'.,::-',(':',.

FI

GURE

130.

Ratio

Change

Adjustment

change

is

not

occurring

at

the

negative

four

position,

thus

the

arm assembly

is

operating

as one sol id arm

at

this

position.

In

Figure 130C

the

correct

amount

of

ratio

change

is

in

the

system. All positions

from

the

-3

to

the

+5

detent

the

same as

the

-5.

Note

that

when

the

-3

de

tents

the

same as

the

-5,

the

detenting

of

the

-4

is

slightly

dif-

ferent.

This

is

caused

by

the

ratio

change.

No

attempt

should be made

to

control

the

detenting

of

the

-4

posi-

tion

because

its position may

vary

on

each

machine·de-

pending

on

the

amount

of

ratio

change

required

(of

each

machine)

to

make

the

-3

detent

the

same as

the

-5.

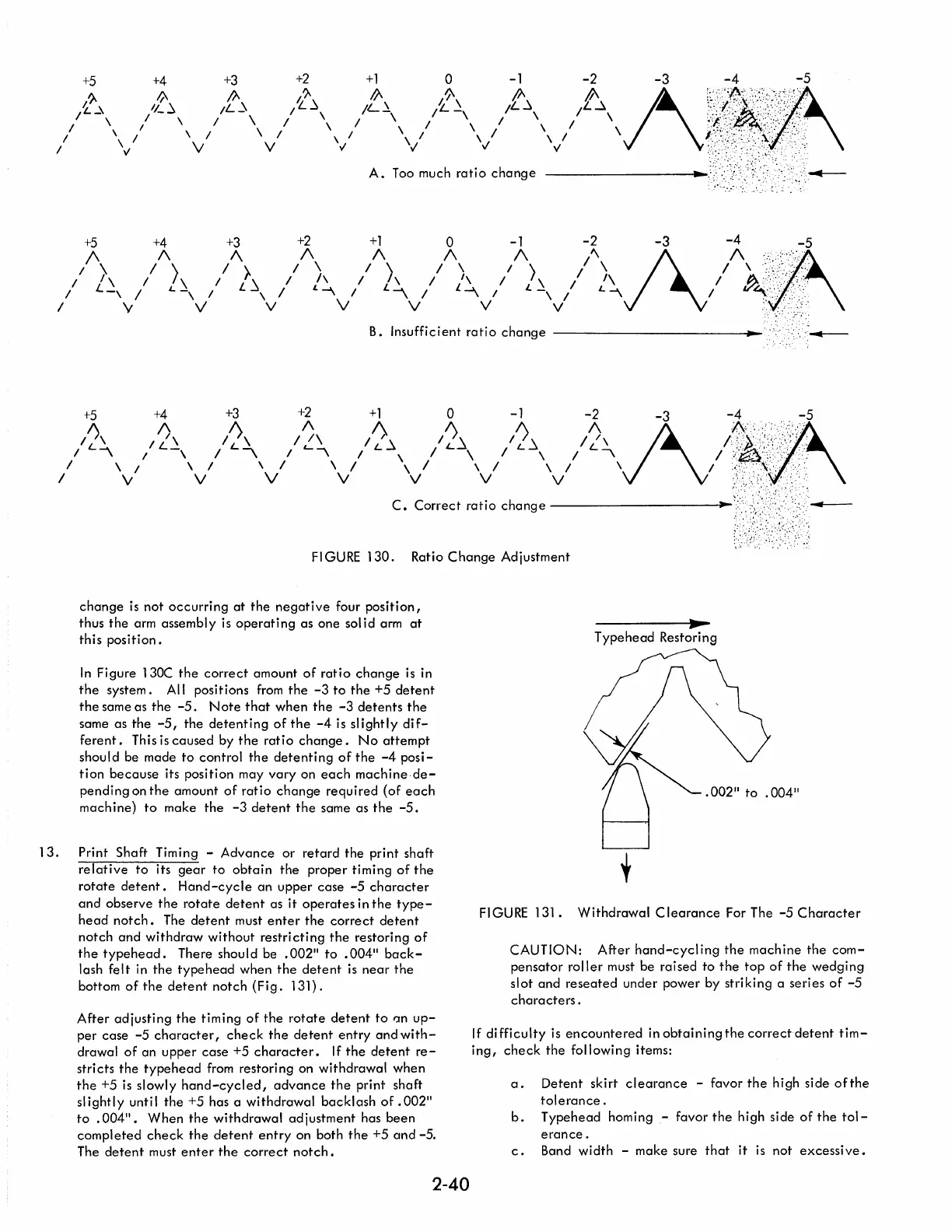

13.

Print Shaft Timing -

Advance

or

retard

the

print shaft

relative

to

its

gear

to

obtain

the

proper timing

of

the

rotate

detent.

Hand-cycle

an

upper case

-5

character

and

observe

the

rotate

detent

as

it

operates

in

the

type-

head

notch.

The

detent

must

enter

the

correct

detent

notch

and

withdraw

without

restricting

the

restoring

of

the

typehead.

There should be

.002"

to

.004"

back-

lash

felt

in

the

typehead

when

the

detent

is

near

the

bottom

of

the

detent

notch

(Fig.

131).

After

adjusting

the

timing

of

the

rotate

detent

to

IJn

up-

per

case

-5

character,

check

the

detent

entry

and

with-

drawal

of

an upper

case

+5

character.

If

the

detent

re-

stricts

the

typehead

from restoring on withdrawal when

the

+5

is

slowly

hand-cycled,

advance

the

print shaft

slightly

until

the

+5 has a

withdrawal

backlash

of

.002"

to

.004".

When

the

withdrawal

adjustment

has

been

completed

check

the

detent

entry

on both

the

+5

and

-5.

The

detent

must

enter

the

correct

notch.

2-40

Typehead

Restoring

FI

GURE

131.

Withdrawal

Clearance

For The

-5

Character

CAUTION:

After

hand-cycl

ing

the

machine

the

com-

pensator

roller

must be raised to

the

top

of

the

wedging

slot

and

reseated

under power by striking a series

of

-5

characters.

If

di

fficulty

is

encountered

in

obtaining

the

correct

detent

tim-

ing,

check

the

following items:

a.

Detent

skirt

clearance

- favor

the

high side

ofthe

tolerance.

b.

Typehead homing - favor

the

high side

of

the

tol-

erance.

c.

Band width - make sure

that

it

is

not

excessive.

Loading...

Loading...