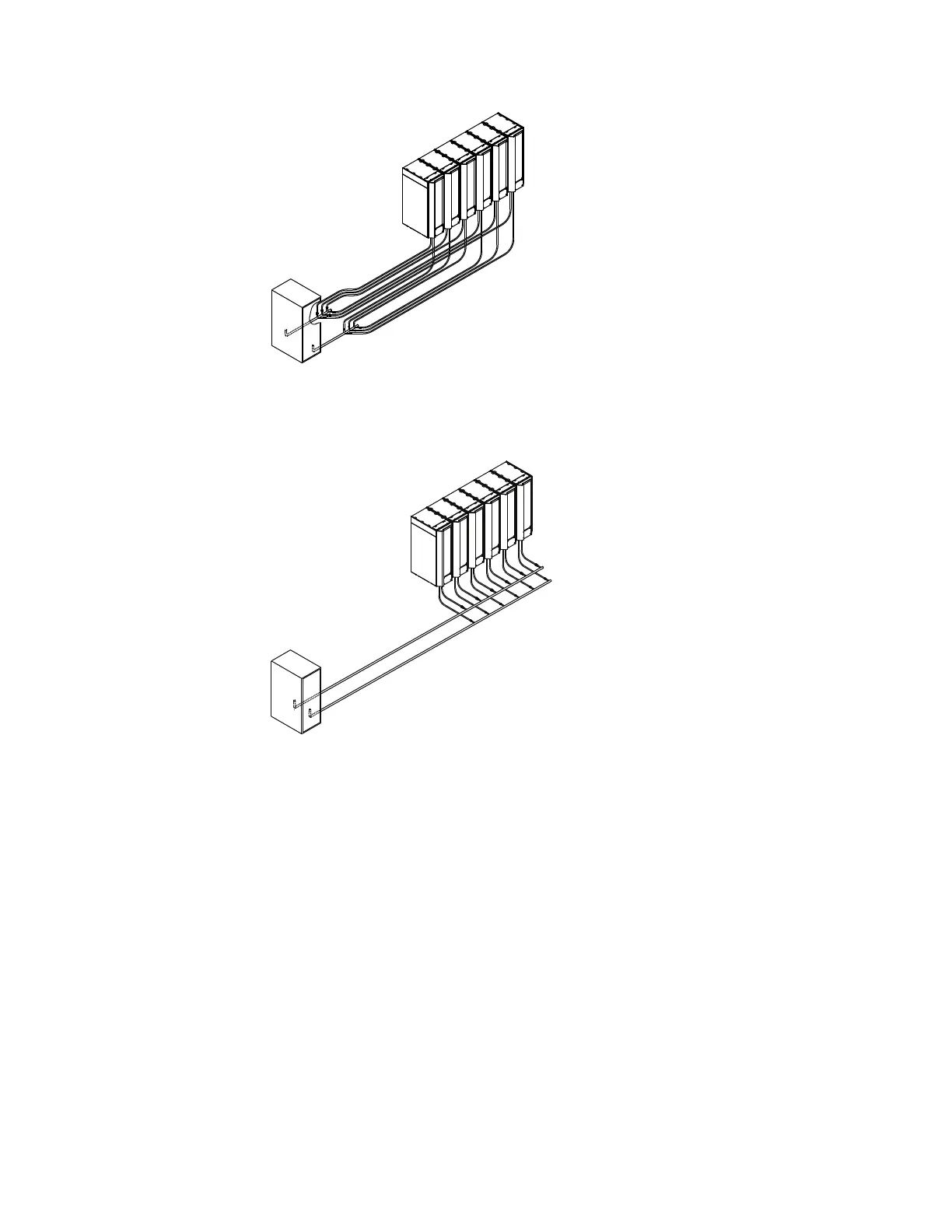

Figure 26 shows an extended manifold layout.

Flexible hoses and connections to manifolds and heat

exchangers

Pipe and hose configurations can vary. You can determine the best configuration

for your installation by analyzing the needs of your facilities, or a site preparation

representative can provide this analysis.

Flexible hoses are needed to supply and return water between your hard plumbing

(manifolds and cooling distribution units) and the heat exchanger, allowing needed

movement for opening and closing the rack rear door.

Hoses are available that provide water with acceptable pressure-drop

characteristics and that help prevent depletion of some corrosion inhibitors. These

hoses must be made of peroxide cured ethylene propylene diene monomer

(EPDM), non-metal-oxide material and must have Parker Fluid Connectors

quick-connect couplings at each end. These couplings are compatible with the heat

exchanger couplings. Hose lengths from 3 to 15 meters (10 - 50 ft), in increments of

3 meters (10 ft), are available. Hoses that are longer than 15 meters (50 ft) might

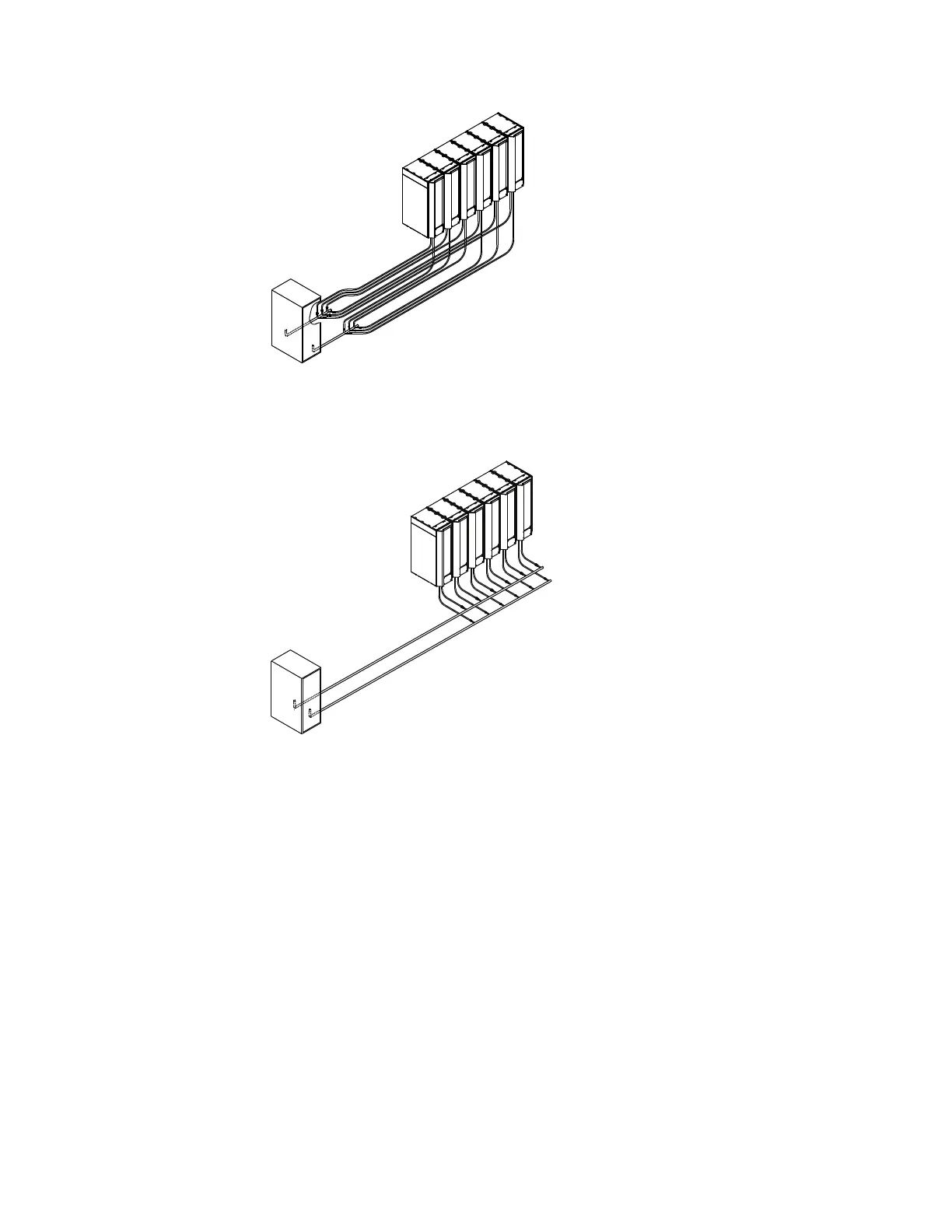

Figure 25. Typical central manifold (at a central location for multiple water circuits)

Figure 26. Typical extended manifold (located along aisles between racks)

Chapter 10. Planning for the rear-door heat exchanger 83

Loading...

Loading...