32

INITIAL LIGHTING

THE DISPLAY

The user control has one neon and one display to inform

the user about the status. The display will show the status

of the boiler. The neon will show the status of the ame.

If no ame is detected the neon is off. When the ame is

detected the neon will be lit permanently.

Below is a list with display function in normal operation.

Standby, no demand for heat present.

Boiler is active for central heating.

Boiler is active for domestic hot water.

Boiler is heating up the plate heat exchanger.

Boiler is active for boiler frost protection.

Boiler is in lockout for a specic error. Display will be

blinking, alternating with a number or letter to show

which error is detected.

Boiler has a fault for a specic error. Display will be

blinking, alternating with a number or letter to show

which error is detected.

Note: Boiler frost protection - boiler res if temperature is

below 5 degrees C.

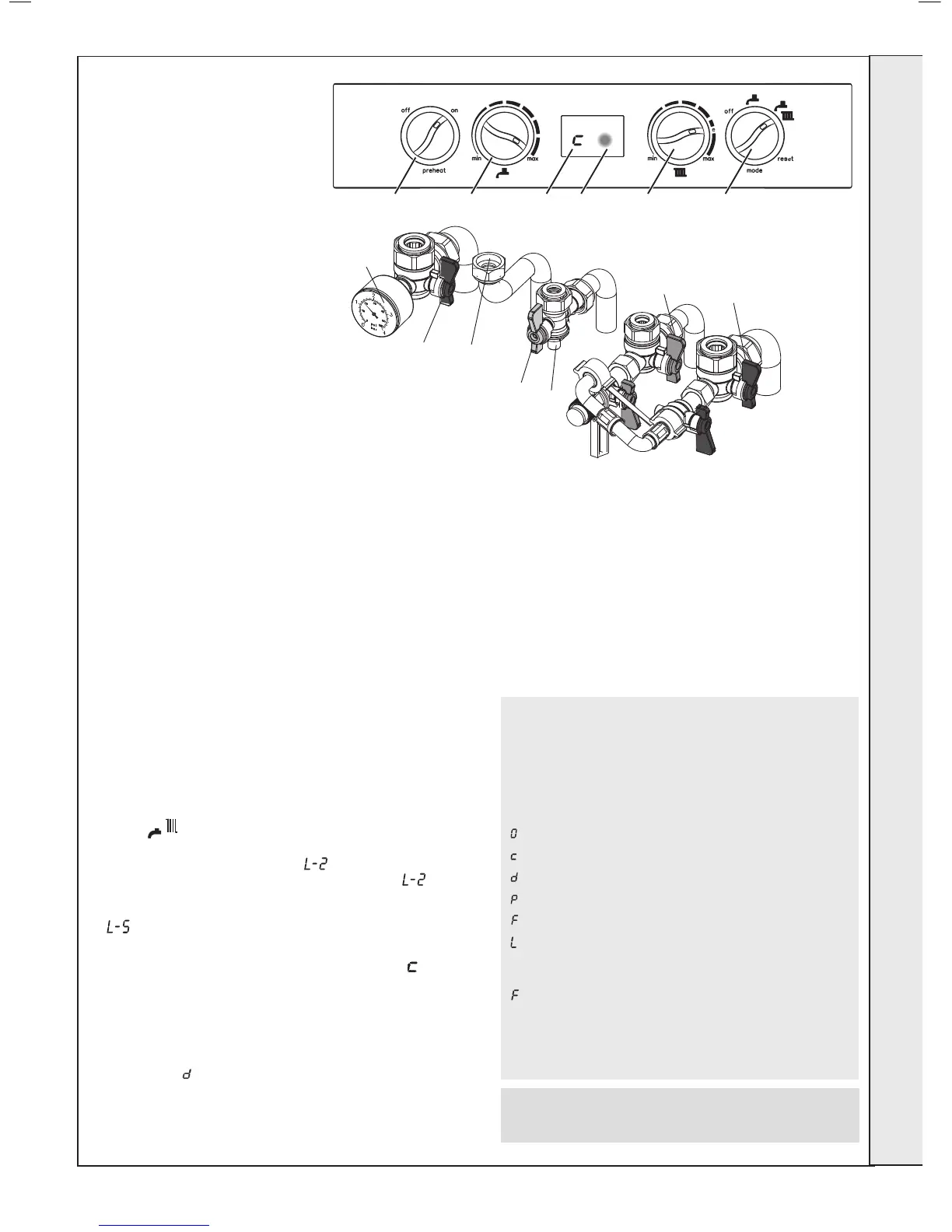

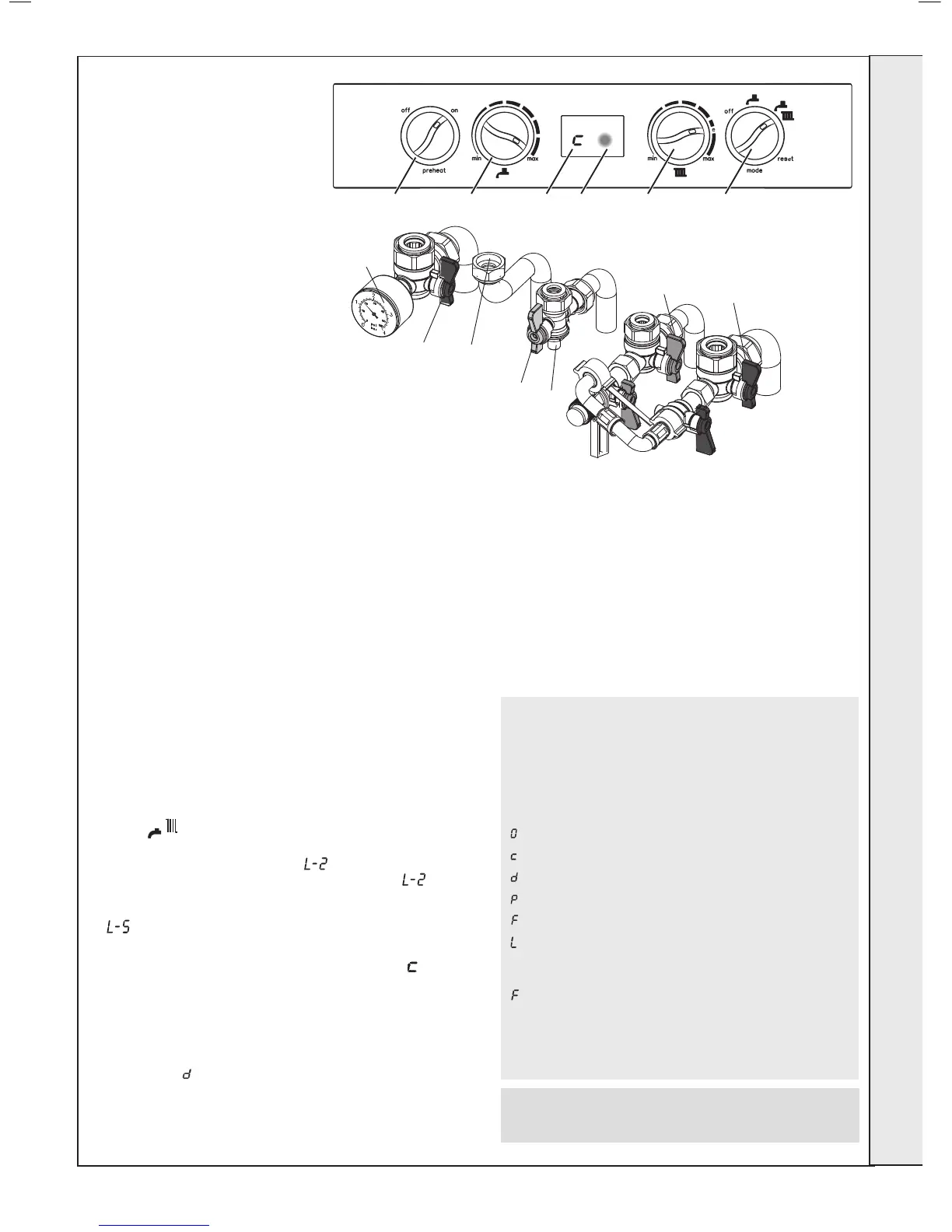

Legend

A. Pre-heat On/off

B. DHW temperature control

C. CH temperature control

D. Off/Summer/Winter/Reset Control

E. Boiler Status

F. Burner ‘on’ indicator

G. CH Flow Isolating Valve

H. Pressure Gauge

J. Gas Inlet Pressure Test Point

K. Gas Service Cock

L. DHW Inlet Valve

M. CH Return Isolating Valve

N. DHW Outlet

1. Check that the system has been lled and that the boiler is not

airlocked. Ensure the automatic air vent cap is open. Note.

It is important the burner is not operated before the system is fully

vented of air. If it is necessary to operate the appliance pump to

assist venting of the air this must be done with the gas service cock

turned off.

2. Ret the boiler front panel. Refer to Frame 37.

3. Check that the drain cock is closed and that the CH and DHW

isolating valves (L, M, and G) are OPEN.

4. Check that the electrical supply is OFF.

5. Check that the boiler mode control knob (D) is off.

6. Check that the gas service cock (K) is OPEN.

7. Slacken the screw in the inlet pressure test point (J) and connect

a gas pressure gauge via a exible tube.

8. Switch the electricity supply ON and check all external controls are

calling for heat.

CENTRAL HEATING

9. Set the CH temp control (C) to max and turn the mode control knob

(D) to

. The boiler control should now go through its ignition

sequence until the burner is established.

10. If the boiler does not light code will be displayed. After 5

attempts the boiler will lock out and display fault code constantly.

Reset the boiler (Refer to Frame 3438). The boiler will repeat its

ignition sequence. If reset occurs 5 times within 15 minutes then

will be shown. If power is removed this will be reset.

When the burner is established the BLUE ‘Burner On’ neon (F) will

be illuminated, the LED display (E) will show status

.

DOMESTIC HOT WATER

11. With the boiler ring, set the DHW Temp Control knob (B) to

maximum and fully open a DHW tap.

The boiler should continue to run and the LED display (E) should

show status

12. Ensure that with the boiler operating the dynamic gas pressure is

able to obtain maximum output. Refer to Table 2.

IMPORTANT

The gas input to the burner is regulated by the gas

valveaccordingtotheairowproducedbythefan.

It is NOTuser-adjustable.Anyinterferencetosealed

settings on the gas valve will adversely affect operation

and render our warranty void.

For additional gas supply information refer to “Gas Supply”

on page 8.

13. Turn off the DHW tap.

Note. The boiler incorporates a fan overrun cycle which

MUST NOT be prematurely interrupted by isolation of the

mains electricity supply.

Loading...

Loading...