SERVICING

Ideal Logic Combi - Installation and Servicing

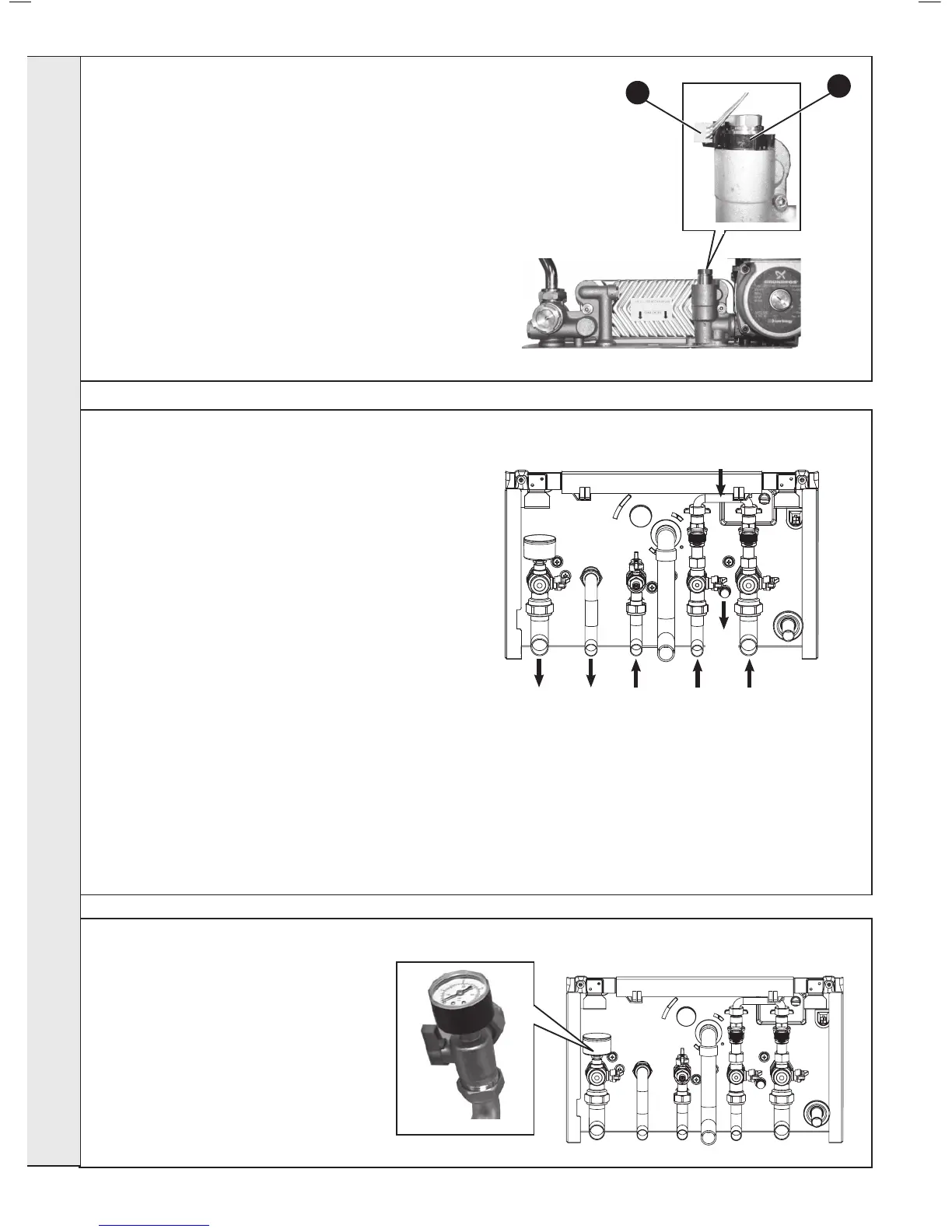

1. Refer to Frame 43.

2. Drain the heating system. Refer to Frame 57.

3. Unscrew the pressure gauge and discard.

4. Fit new pressure gauge, using suitable jointing

compound.

5. Rell the boiler. Refer to Frame 24.

6. Check operation of the boiler. Refer to Frames

32 & 33.

58

PRESSURE GAUGE RENEWAL

57

DRAINING THE BOILER

DOMESTIC HOT WATER CIRCUIT

1. Refer to Frame 43.

2. Close all the DHW water isolating valves on the boiler inlet.

3. To drain the domestic hot water circuit: As there is no direct drain for the domestic hot water circuit, depending on the location

of the boiler, opening the lowest hot water tap may drain this circuit. However it must be noted that some residual water will be

experienced during replacement of components.

4. After replacing any component on the boiler, close tap, close the drain valve and open all system isolating valves (re-pressurise

as appropriate by re-connecting the lling loop, refer to Frame 26) before proceeding to check operation of the boiler.

5. Disconnect lling loop. Refer to Frame 24.

6. Check operation of the boiler. Refer to Frames 32 & 33.

204626-9692d

Gas CH

Return

Filling Loop

DHW

Inlet

DHW

Outlet

CH

Circuit

Drain

CH

Flow

CENTRAL HEATING CIRCUIT

1. Refer to Frame 43.

2. Close all the CH water isolating valves on the boiler inlet.

3. To drain the primary heat exchanger circuit: Open the drain

valve and attach a length of hose to the CH drain point.

4. After replacing any component on the boiler, remove the

hose, close the drain valve and open all system isolating

valves (re-pressurise as appropriate by re-connecting the

lling loop, refer to Frame 30) before proceeding to check

operation of the boiler.

5. Disconnect lling loop. Refer to Frame 24.

6. Check operation of the boiler. Refer to Frames 32 & 33.

56

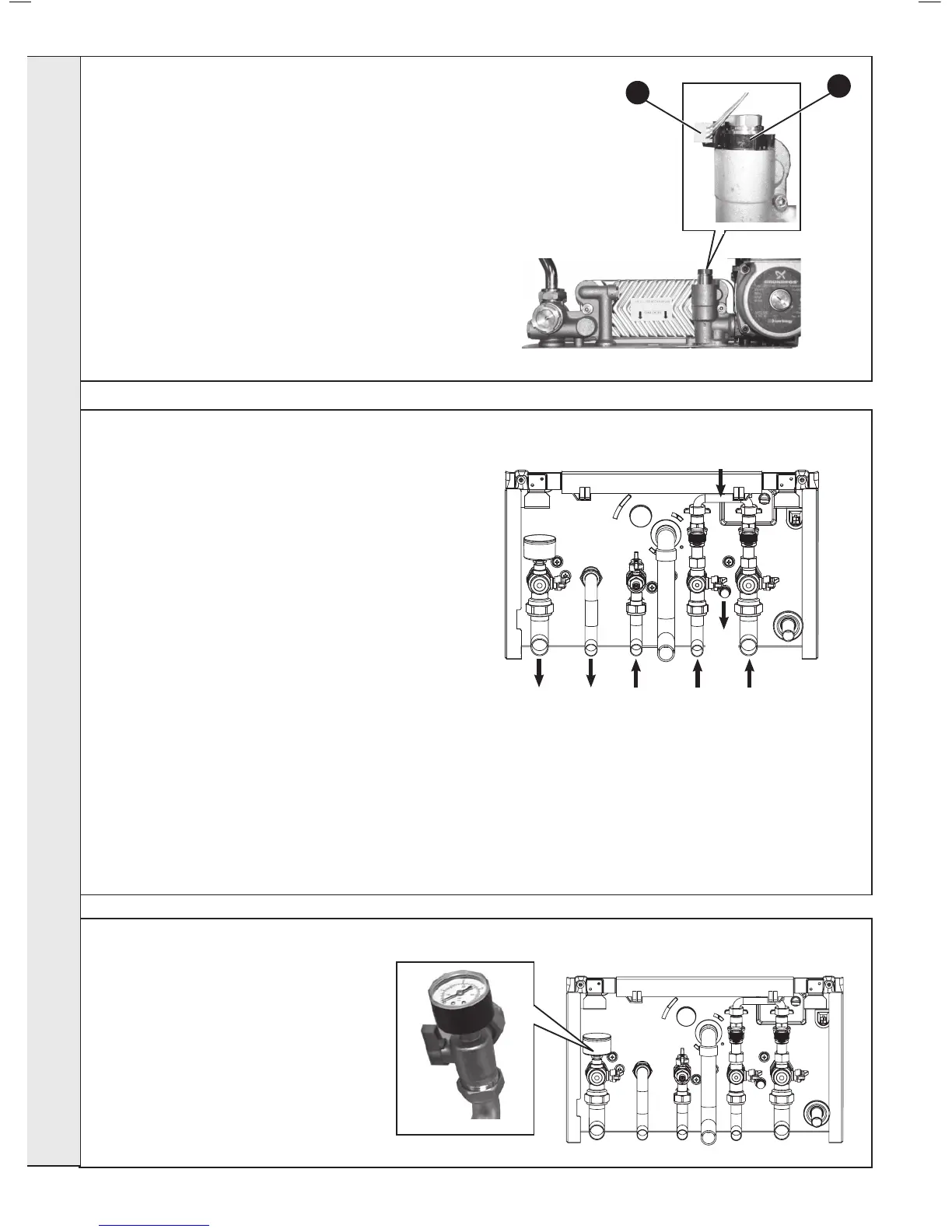

DHW FLOW TURBINE SENSOR REPLACEMENT

1. Refer to Frame 43.

2. Remove condensate trap/siphon. Refer

to Frame 53.

3. Lift off the ow turbine sensor plastic

retaining clip.

4. Unplug the electrical connection and

transfer to new turbine sensor.

5. Reassemble in reverse order.

6. Check operation of the boiler. Refer to

Frames 32 & 33.

3

4

SERVICING

Loading...

Loading...