23

UK

► Arrange for a bore hole in the tank lid� It must have a minimum diameter (d) to

enable sufficient transfer of the measured signal to the probe (fig� 6-10)� The

diameter depends on the wall thickness of the tank lid:

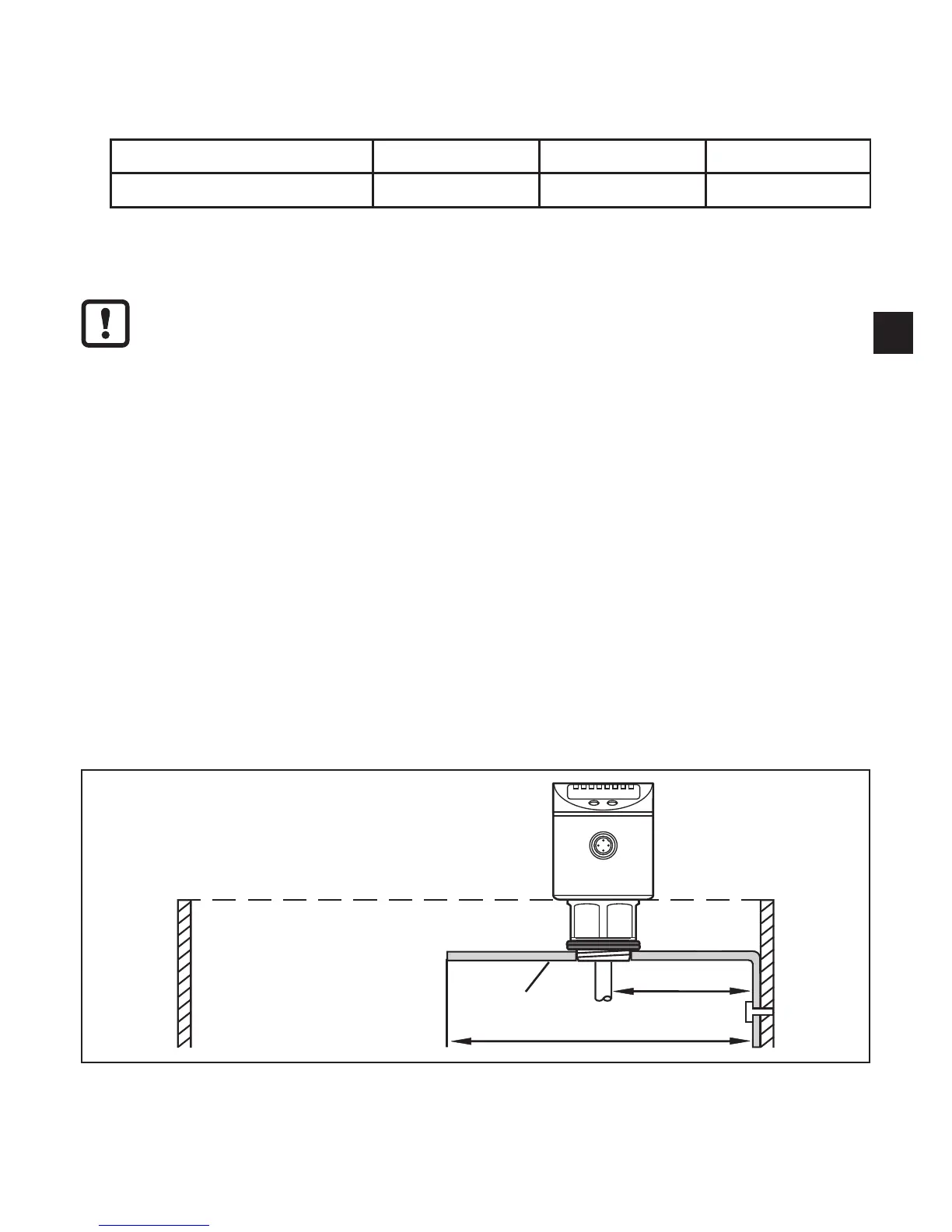

Wall thickness [mm] 1���5 5���8 8���11

Bore hole diameter [mm] 35 45 55

► Install the flange plate with the flat surface showing to the tank and fix it with

appropriate screws�

A seal (B in fig� 6-11) can be inserted between flange plate and tank� Some

flange plates are supplied with a seal�

► Ensure cleanness and evenness of the sealing areas, especially if the tank is

under pressure� Tighten the fixing screws sufficiently�

► Screw the unit into the flange plate using the process connection and tighten

firmly�

► Make sure that the supplied sensor seal (A in fig� 6-11) is correctly positioned�

6.4.3 Installation in open tanks

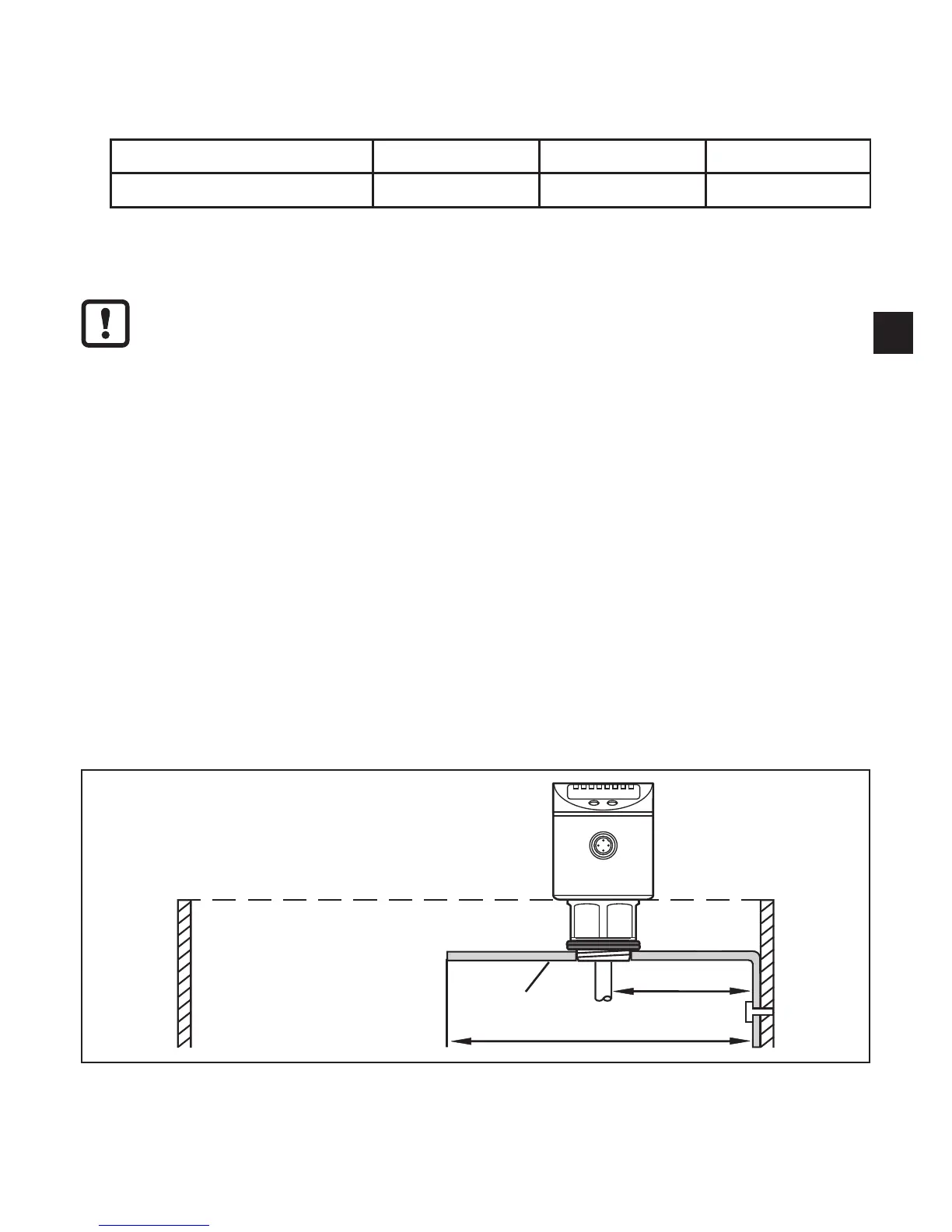

► For installation in open tanks, use a metal fixture to install the unit� It serves

as a launching plate (R); minimum size: 150 x 150 mm for a square fixture,

150 mm diameter for a circular fixture�

► If possible, mount the unit in the middle of the fixture� The distance D2 must not

be below 40 mm, higher for probe lengths > 70 cm and in case of heavy soiling

(→ 6.1.1):

D2

150 mm

R

► The lower edge of the process connection should be flush with the installation

environment (see fig� 6-7)�

► Avoid non-flush installation (see fig� 6-8)�

Loading...

Loading...