TRADUCTION OF THE ORIGINAL INSTRUCTIONS FOR USE

BS 400/60 AFI-Eing ED.2011 rev.00 9/60

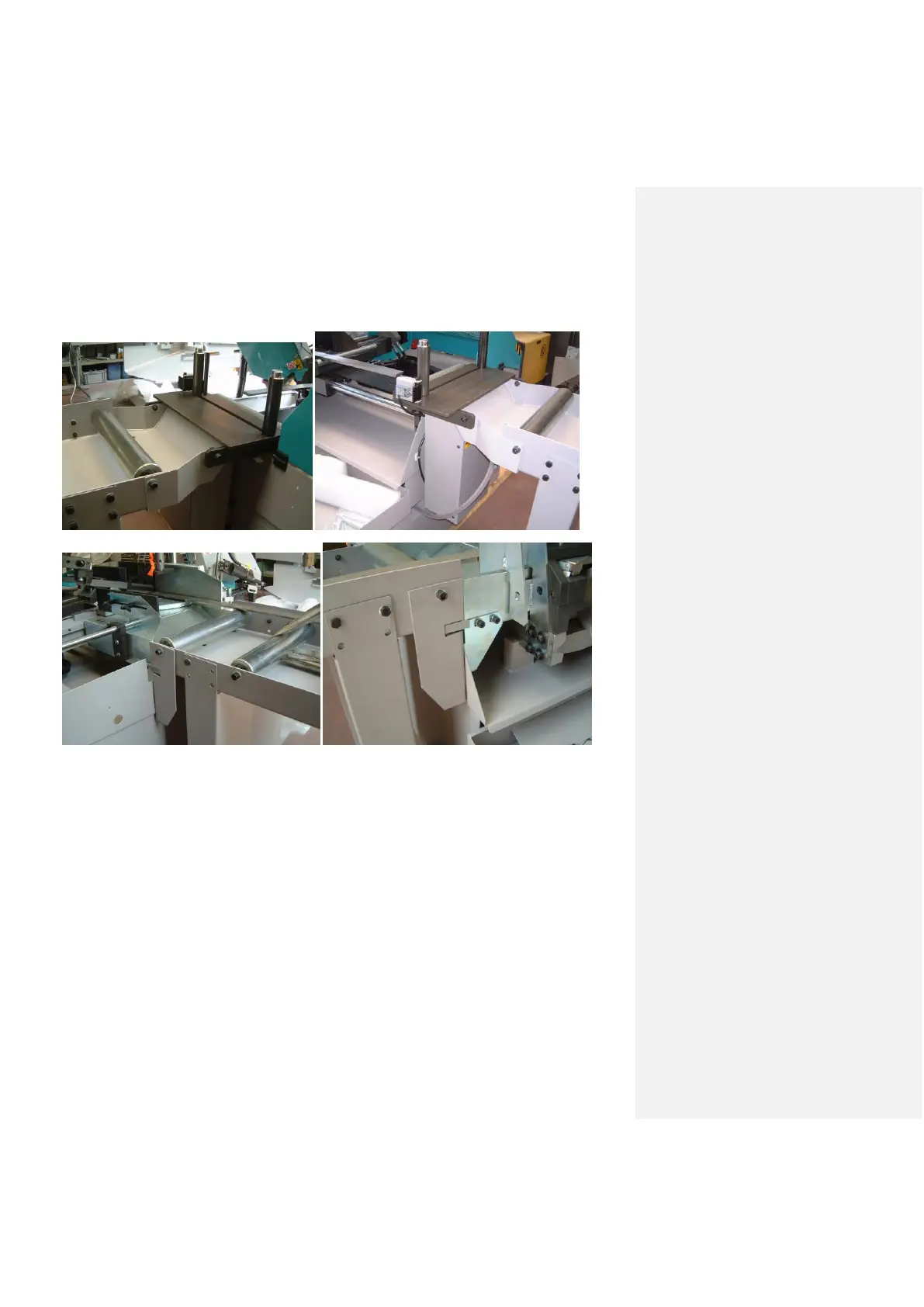

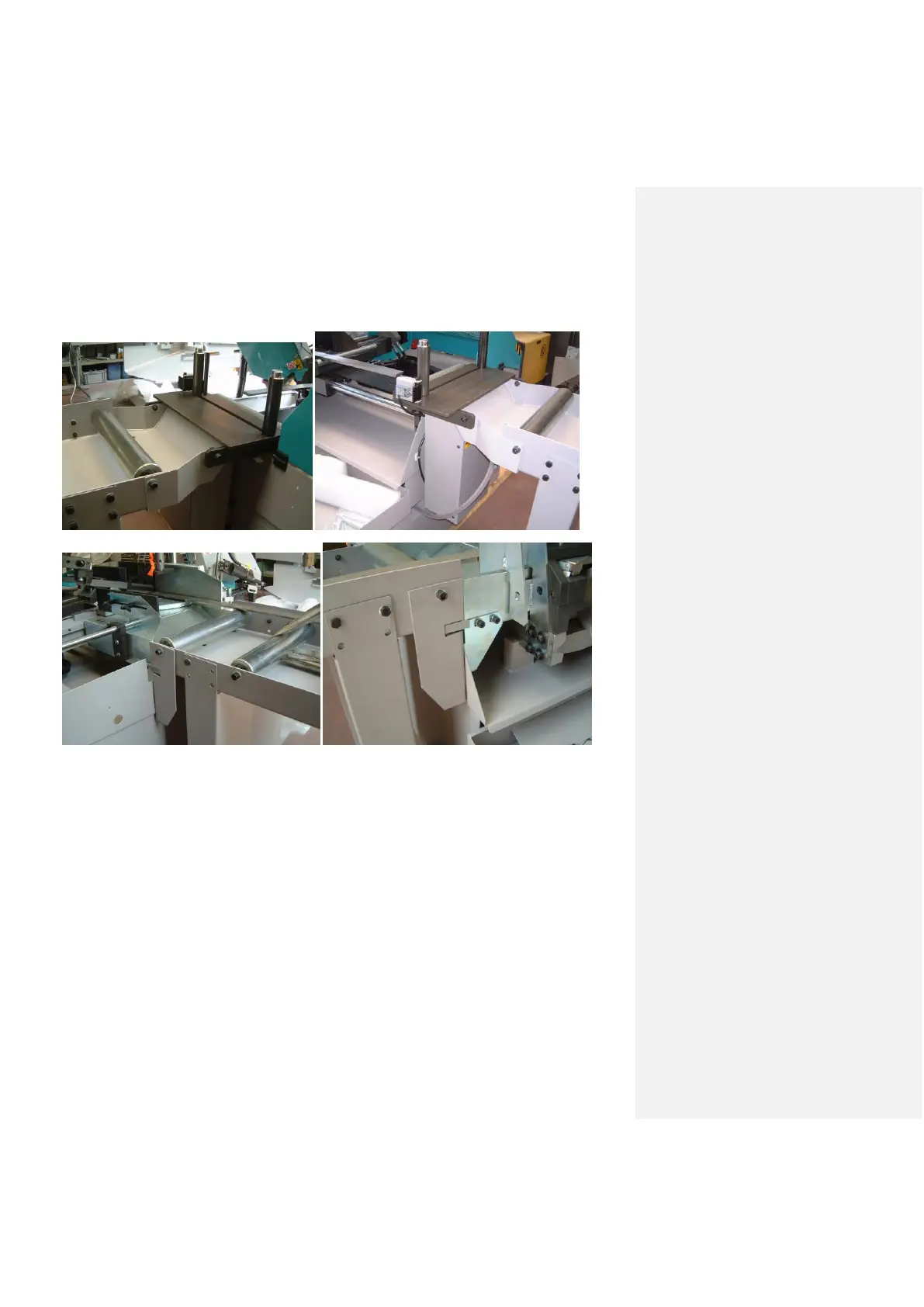

Loading/Unloading Roller Tables – ON REQUEST - To install them correctly, it is necessary first of all to level

and fix the machine. They are comprised of modular steel sheets, 1.5 meter long, 450 mm large.

To connect it to the machine -LOADING SIDE- it is necessary the OPTIONAL part RAB40C comprised with a roller,

as follows pictures:

The unloading table – RIGHT SIDE – can be connected thanks to the OPTIONAL RAKS450

The alignment of the loading/unloading tables must begin with the one closer to the machine, taking as reference

point the worktable and the back jaw. When cutting long bars, fix the table to the floor and make sure the coolant,

which is carried by the bars, doesn’t drop on the floor.

Inverter for variable blade speed - ESC - is an accessory which can be installed when manufacturing the saw and

allows the blade to have a variable speed. It can be adjusted by means of a selector located on the control panel.

In case the maximum power supply threshold is exceeded - for example, because of an excessive cutting pressure

or because the blade remains stuck into the material - the Inverter stops the motor.

To restore it, the main switch has to be turned to 0 (OFF), wait for about one minute and then turn it on I (ON).

In the meantime, try to find out the reason that caused the interruption and eliminate it.

Additional supporting roller for the feeding - it increases the support of the material to cut ( when the bar is

almost finished ). You can assemble it and dismantle easily.

Vice pressure reducer - It allows to reduce the working pressure of the closing jaws compared to the general

pressure of the system. It is a modular unit and it can be assembled also later between valve-holder base and the

hydraulic valve (the one for the valve of the main vice is supplied as standard equipment; the one for the feeder

vice is as Optional); it doesn’t require any cable connections.

By opening the front door you can adjust the pressure.

Hydraulic vertical vices for cutting bundles – Connected to the standard vices, they allow to clamp and feed a

bundle of bars; maximum breadth 300mm, minimum breadth 110mm, maximum height 120 mm.If you do not use

this device, remove it thanks to the fast hydraulic connections; the one near to the blade has to be changed with the

Loading...

Loading...