TRADUCTION OF THE ORIGINAL INSTRUCTIONS FOR USE

BS 400/60 AFI-Eing ED.2011 rev.00 10/60

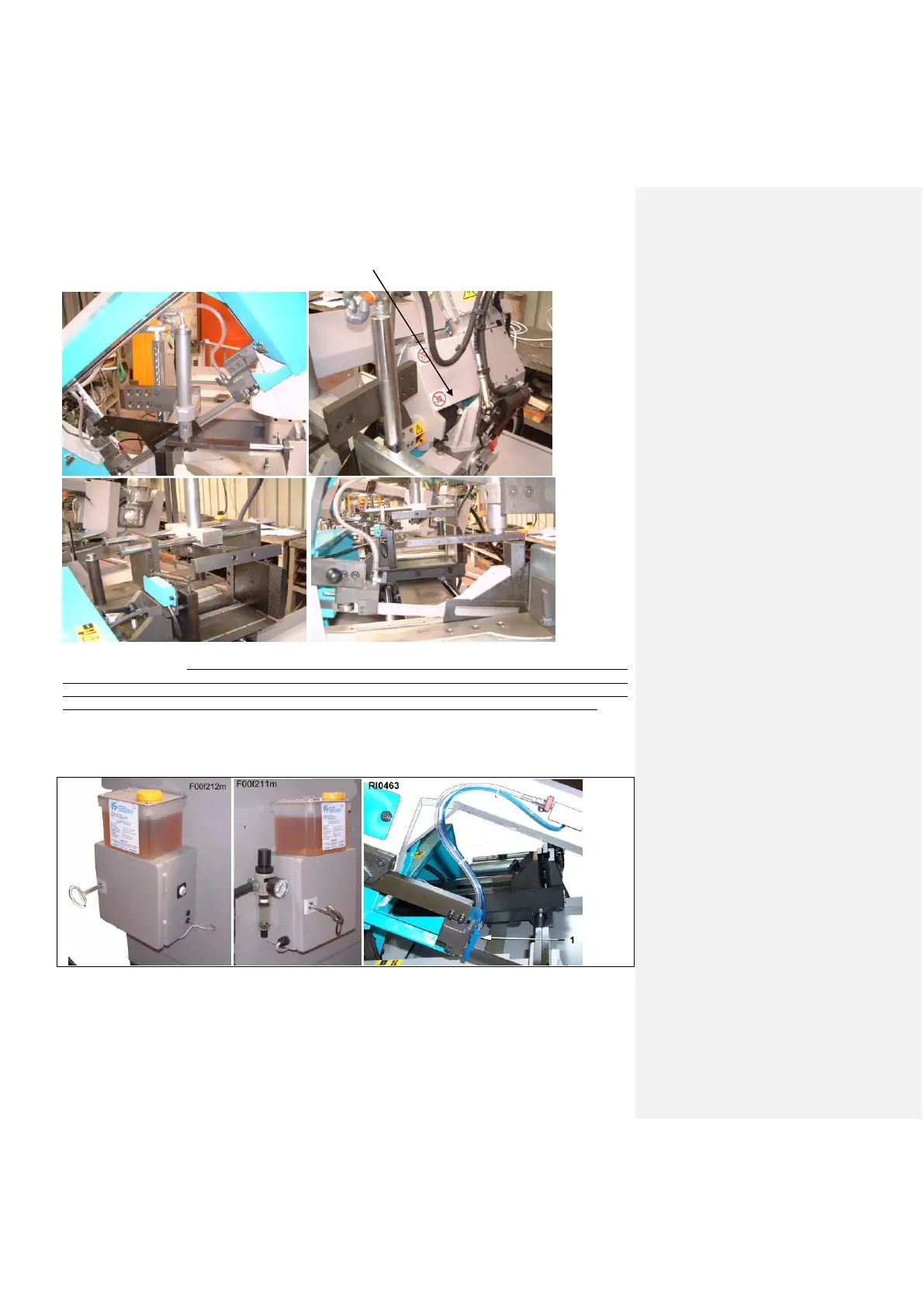

standard vertical vice, that is supplied as a remote part. Regulate the upper position of the saw-frame by the

stroke-end screw (see above).

. .

..

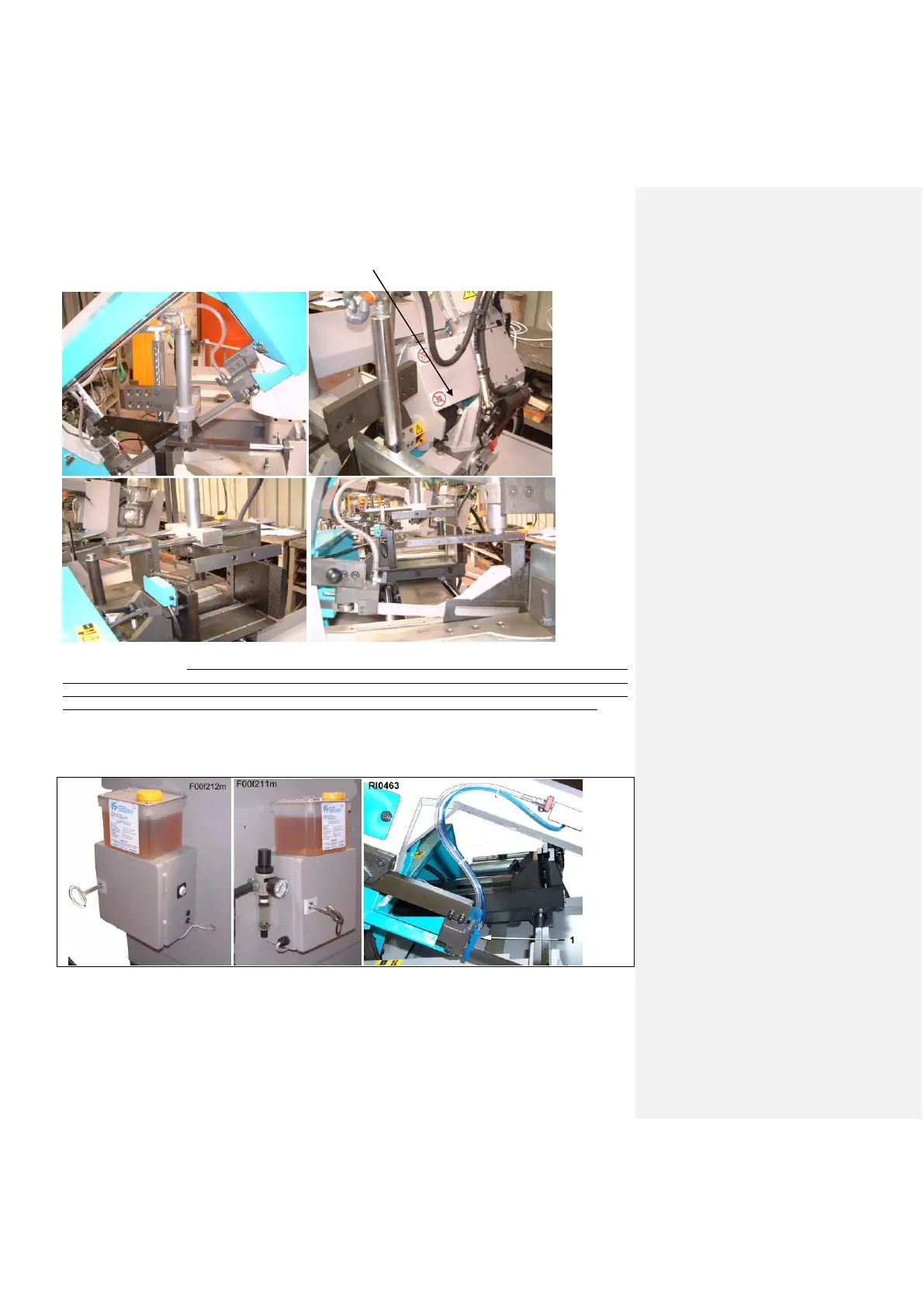

Minimal lubrication – THE MINIMAL LUBRICATION SYSTEM APPLIED TO THE BANDSAW ALLOW TO

ELIMINATE ALMOST COMPLETELY THE TRADITIONAL COOLANT SYSTEM. THE MATERIAL IS MUCH

CLEANER AND THERE IS NO WASTE/SPILLING OF COOLANT AND WATER, CONTRIBUTING THUS TO

PRESERVING NON-RENEWABLE ENERGY SOURCES AS WELL. IT IS ACTIVE ONLY DURING THE CUT.

IT IS COMPRISED OF A NOZZLE – RI0463– WITH 3 MICRO-HOLES TO SPREAD THE OIL ON THE BLADE, A

TANK WITH DEVICE –F00f211m- TO ADJUST THE OIL FLOW AND ANOTHER TO REGULATE THE AIR

PRESSURE. THE 24V LOW TENSION SWITCH – F00f212m – ALLOWS TO STOP IT AT ANY TIME AND GO

BACK TO THE NORMAL STANDARD COOLANT SYSTEM.Remove the nozzle to obtain the maximal cutting

capacity.

Voltage transformer - place it between the electric supply of the premises and the electric supply of the machine. It

allows to work with a different voltage than the standard one (that is 400V / 50 Hz). Available voltages: 230V, 460V,

500V, 575V.

10 - BLADE CHOICE -

Loading...

Loading...