TRADUCTION OF THE ORIGINAL INSTRUCTIONS FOR USE

BS 400/60 AFI-Eing ED.2011 rev.00 11/60

In this paragraph we recommend the type of blade according to the material to cut. To get the best performance

from this machine it is necessary to understand how to use the tools and what you do not have to do with them. The

blade for this bandsaw must have the following size (mm) :

maximum length = 40300 minimum length = 40100 height = 34 thickness =1,1

The type of blade is also important, usually it’s a bi-metal blade with different HARDNESS, named M42 or SVGLB (

for general purpose, tubes, profiles and solids, available in all pitch type), M51 or SHL (preferred for big

solids of hardening steel, INOX material too, available with 3/4 tooth pitch).

The durability of the teeth increases, and also the fragility, when going from the material M42 to M51.

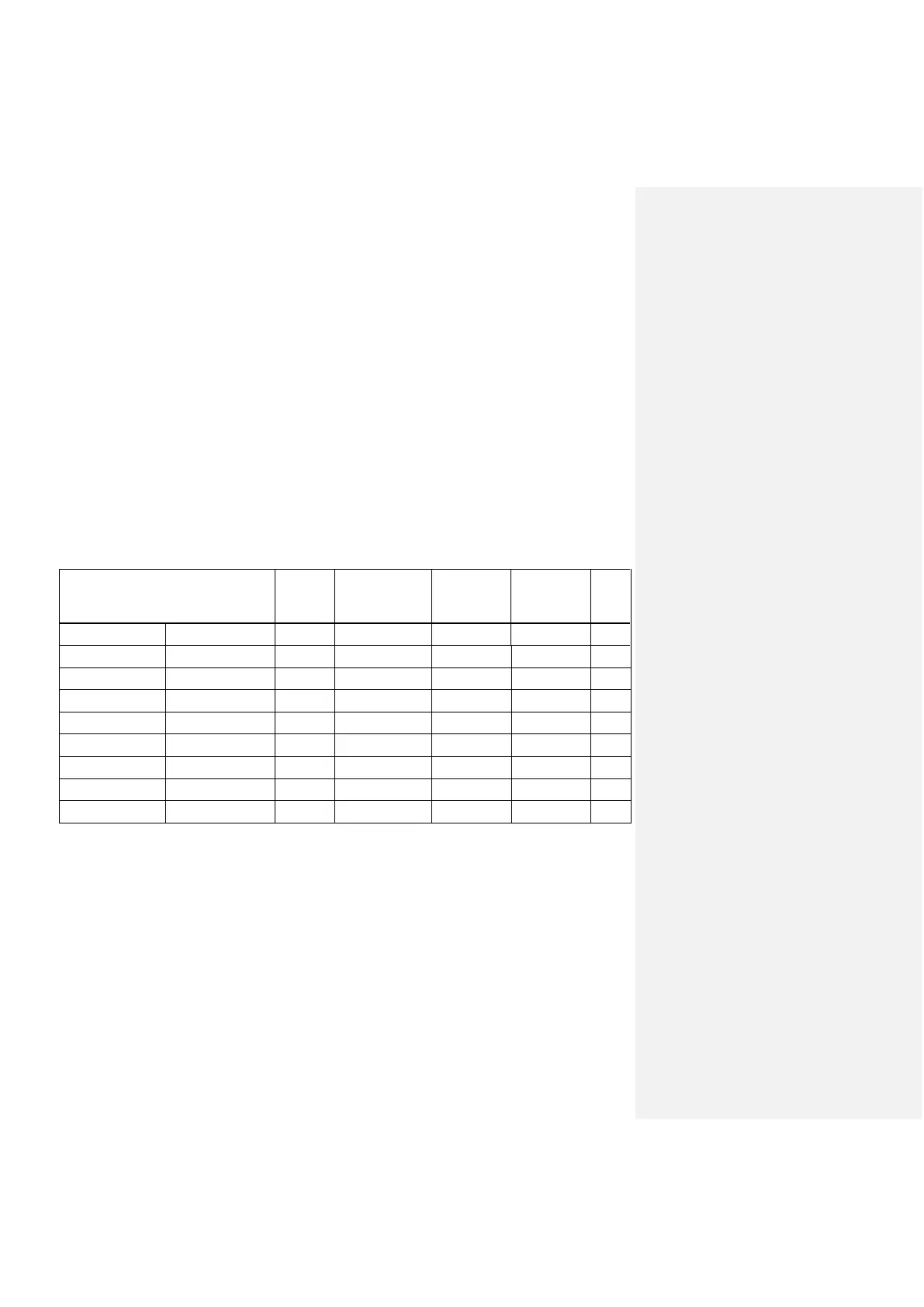

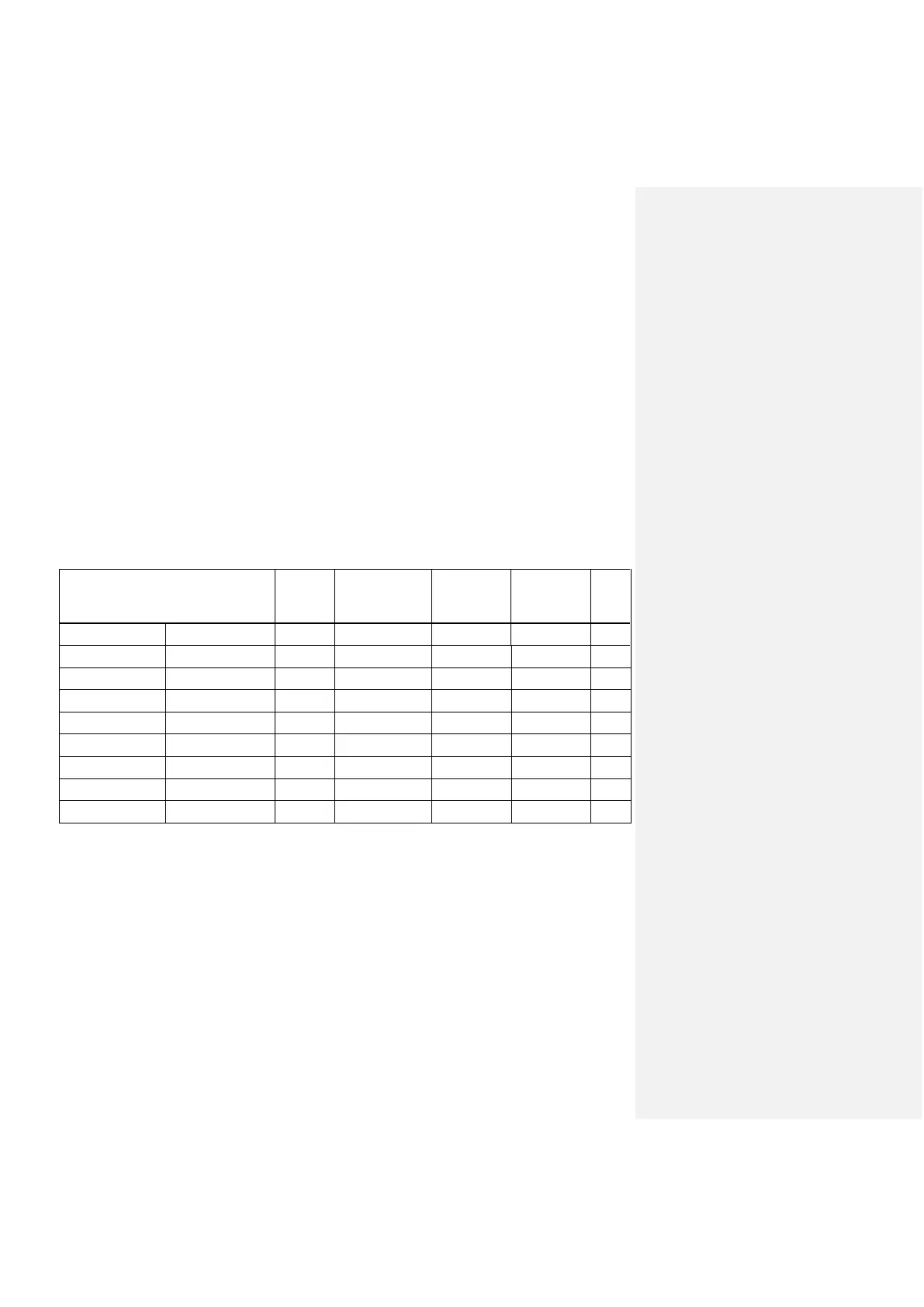

To making a correct cut it’s essential to choose the pitch ( t ) or the number of the teeth per inch (z).

Usually the blade must have a pitch as follows :

- high pitch (small teeth), to cut thin materials, tubular and profiles.

- low pitch (big teeth), to cut solids or particular sections that require at times a big blade effort (for example, the

central part of a U profile), or softer materials as aluminium, copper, soft bronze.

By choosing the right one you can avoid a lot of working errors, get a good cut and the necessary room for the

chips. If you cut more bars at the same time, you must consider them as a single bar and consider the total

size. The following table provide the information for a correct choice, it can also be updated or modified by the

user according to his personal experiences.

Even if blades with constant pitch are available, most bandsaws allow to use blades with variable pitch - groups of

teeth with different pitch between them - which reduce vibrations and noise, improving the quality of the cut and the

performance.

Loading...

Loading...