TRADUCTION OF THE ORIGINAL INSTRUCTIONS FOR USE

BS 400/60 AFI-Eing ED.2011 rev.00 12/60

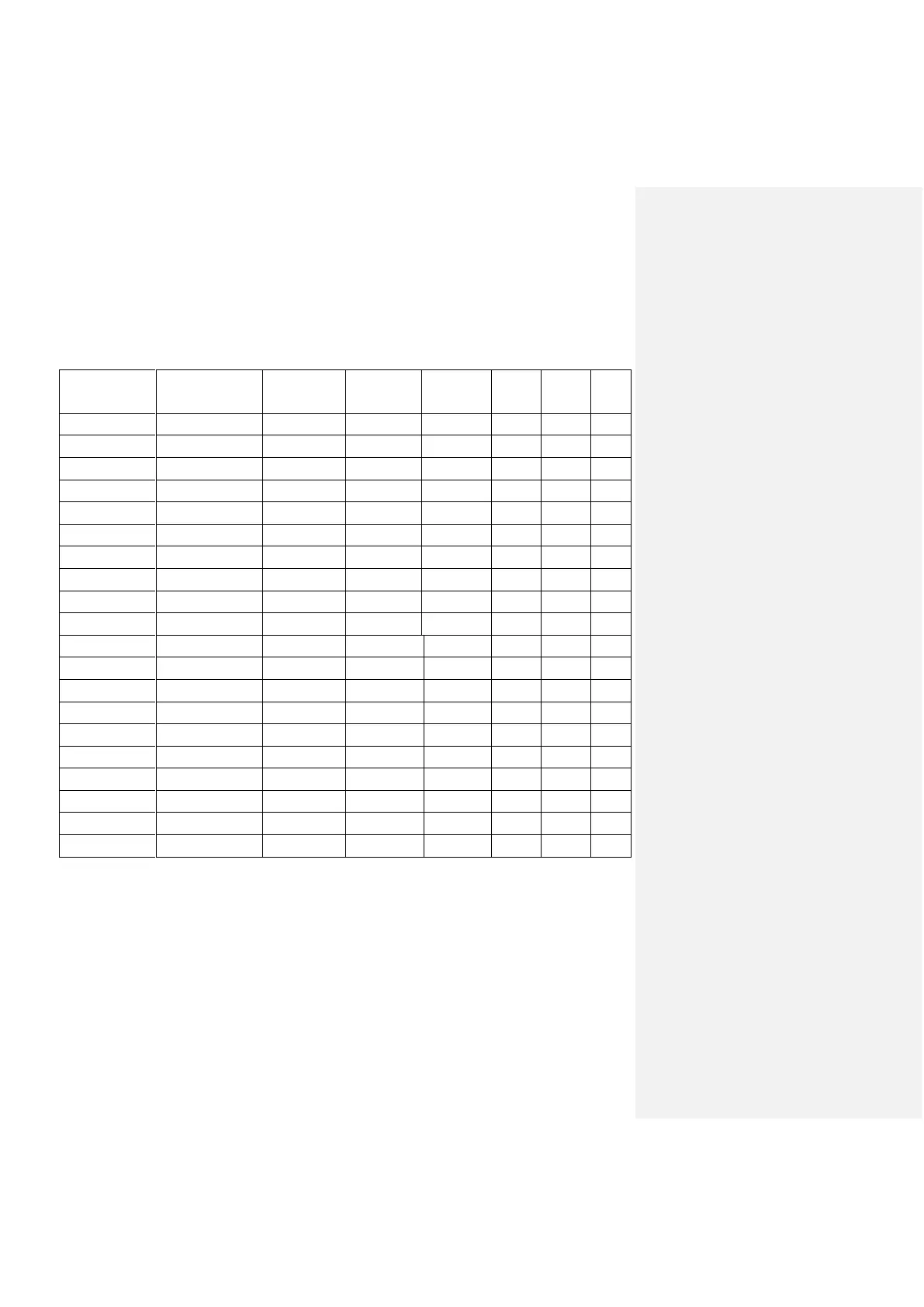

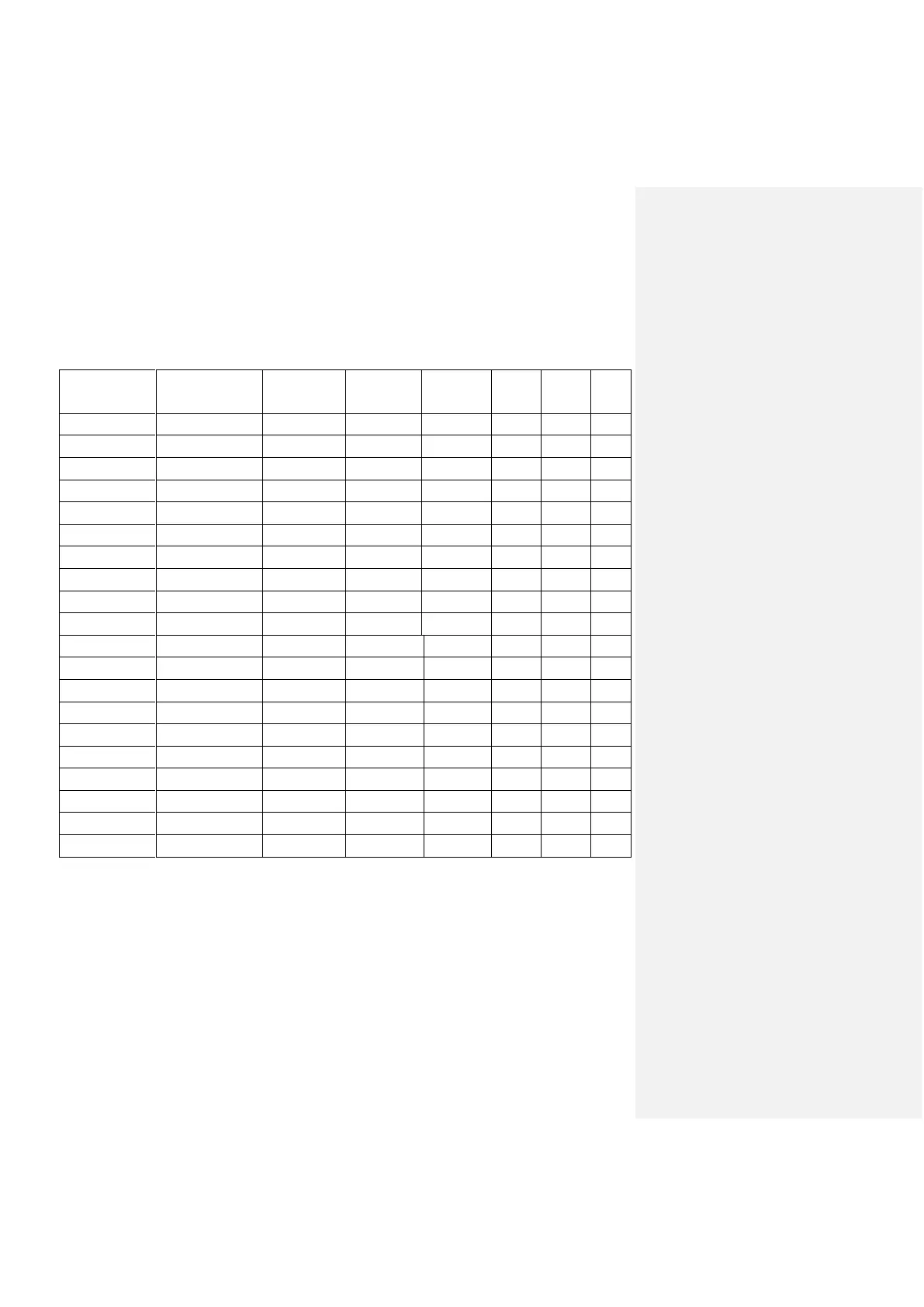

These cutting recommendations are referred to a 100-mm diameter solid bar and a machine with standard

features. For 2-speed machines we suggest the blade speed to use; if it is into bracket ( ), it is recommended to

use a saw with ESC, which grants a continuous blade speed variation.

If the material size decreases, the figures shown can be increased, considering also the type of saw and its

performance and/or some accessories - for example the ESC (Electronic Speed Control) – and vice versa.

Loading...

Loading...