TRADUCTION OF THE ORIGINAL INSTRUCTIONS FOR USE

BS 400/60 AFI-Eing ED.2011 rev.00 22/60

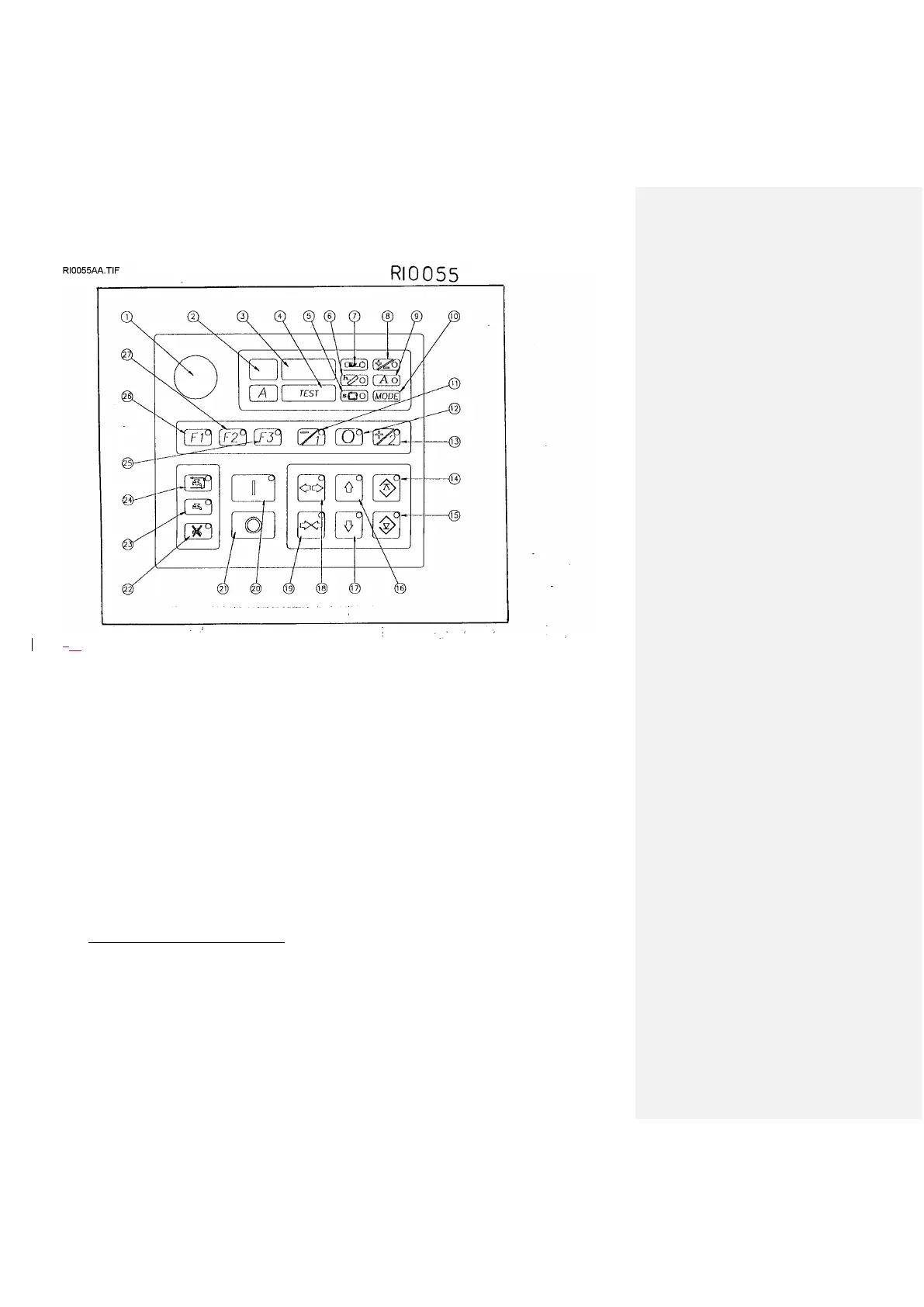

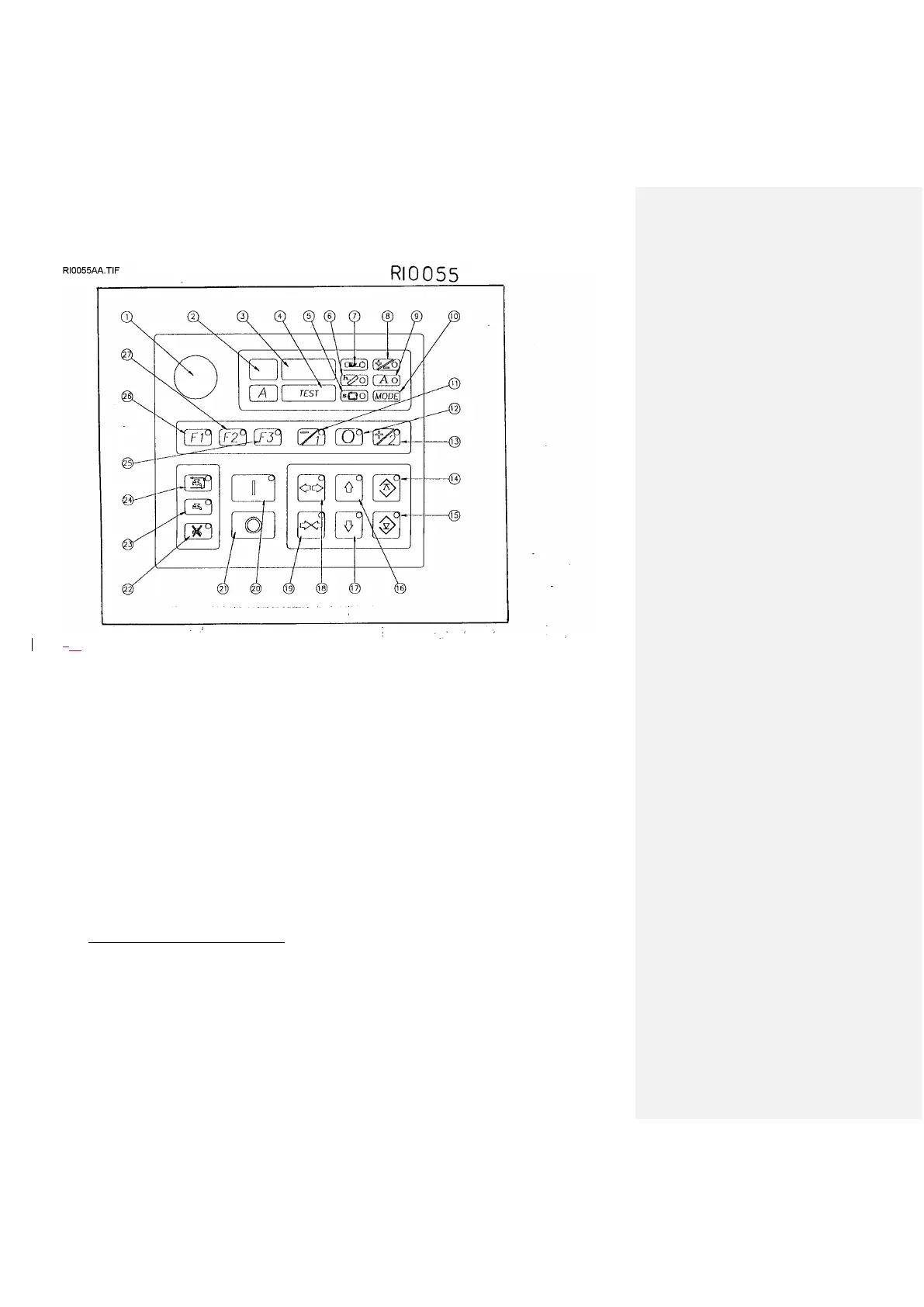

915.4 - CONTROL DESCRIPTION - .

- Main switch with magnetic and thermic protection. It can be locked and is equipped with device to protect it against

power failures.

- Emergency button: it stops all drivers – pos.14/RI0464 – to restore them rotate the button to the right

- Control panel with display – pos.3/RI0464 – (see paragraph KEYBOARD)

Other drivers are located in easily accessible positions:

- hydraulic device to adjust the down-feed speed – pos.12/RI0464

- device to adjust the general pressure – pos.1/RI0426

- manual opening/closing of the frontal vice – pos.10/RI0464

- unlocking of the worktable rotation for miter cutting – pos.6/RI0464, located on the right side of the turning table

- taps of the coolant system – pos.7/RI0464

- locking/unlocking of the mobile forward blade guide – pos.8/RI0464

- lever and wheel to adjust the cutting length – pos. 2,4/RI0442

- locking of the feeder vice – pos.5/RI0442

15.5 - SEMIAUTOMATIC CUTTING SETTING

The original band allows to cut different sections of material, thanks to the variable pitch toothing ( alternate little

teeth with big teeth ), but it is necessary to have the most suitable band for the piece to cut, to get the best machine

performance. So we recommend to read the paragraph BAND CHOICE - for a right use.

Place the material in the vice, leaving 2-3 mm between it and the jaws, necessary for the automatic closing of the

vice. The bar has to be behind the cutting line. Unlock the emergency button if it’s been pushed -/RI0464-

turn on the hydraulic unit motor by pushing the button CLOSE VICES – pos.19/RI0055 – and push it a second time

to close the vice.

Verify that the bar is properly clamped by the jaws and that the clamping pressure is suited – it doesn’t

have to cause a deformation of the material.

The vertical roller – pos. 11/RI0442 – has to be moved close to the bar to help the feeding.

During the semiautomatic cycle, the feeder covering can be open or closed, since the safety end-stroke is

not active.

Loading...

Loading...