INSTALLER

USER

TECHNICIAN

10

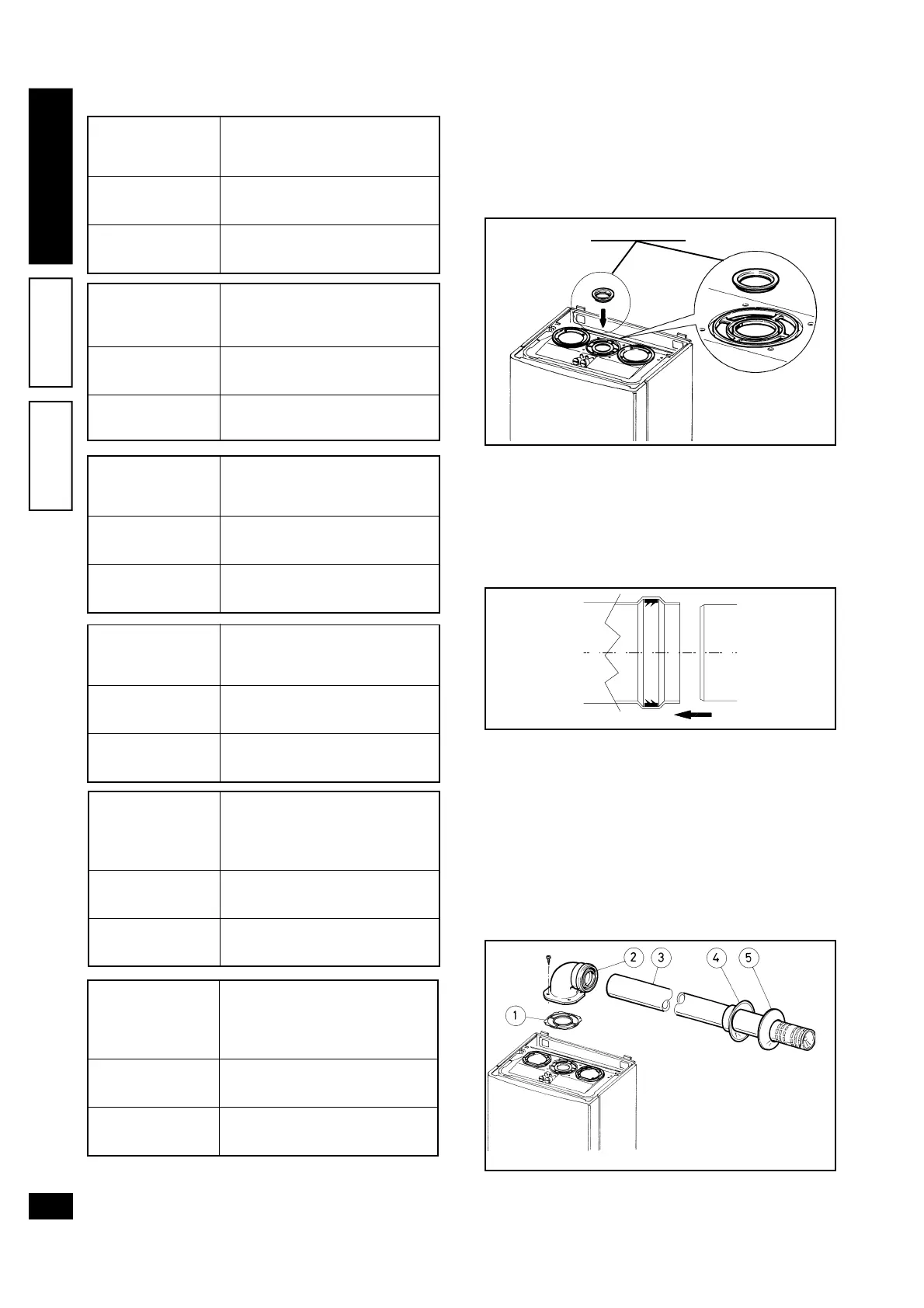

Diaphragm installation. To ensure correct opera-

tion of the boiler, a diaphragm (see figure) must be

installed on output of the sealed chamber before the

intake and exhaust duct. Selection of a suitable dia-

phragm depends on the type of ducting used and

maximum length: calculations can be made using

the values in the tables:

N.W.: Diaphragms are supplied as standard with the

boiler.

* The values for maximum length are considered with

1 metre of exhaust pipe and the remaining on in-

take.

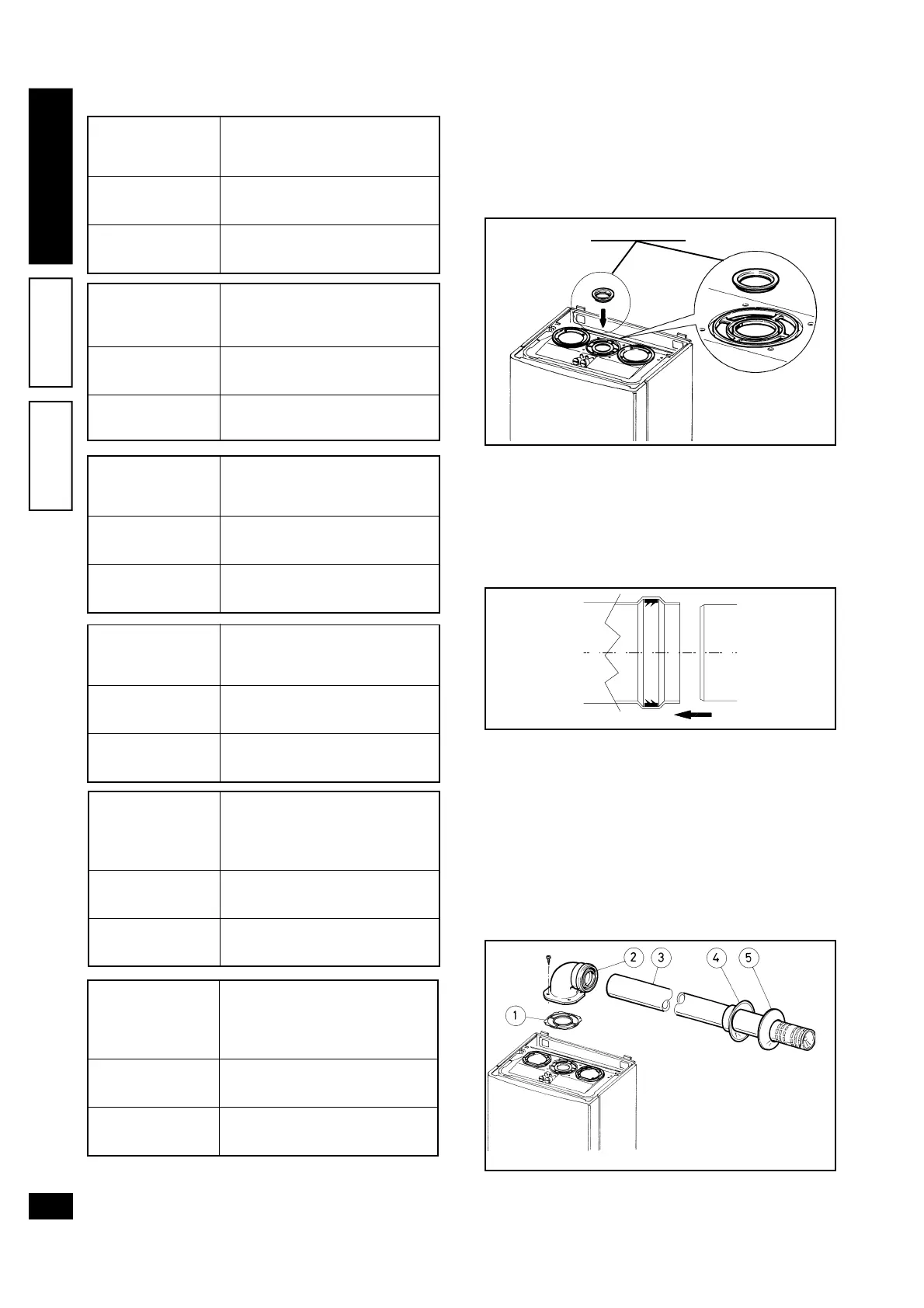

Horizontal intake-exhaust kit Ø60/100. Kit assem-

bly: install the bend with flange (2) on the central

hole of the boiler taking care to insert the seal (1)

and secure by means of the screws supplied with

the kit. Join the male end (smooth section) of termi-

nal pipe (3) to the female section (with lip-seal) of

bend (2) to the end stop and ensure that the internal

and external washers are fitted to achieve perfect

sealing of all couplings.

• Snap-fit couplings of concentric pipes or extensions

and elbow fittings Ø60/100. To install extension

Eolo 27 Maior @ diaphragm table.

Ø 45

NONE

From 0 to 1

Over 1

DIAPHRAGM

Duct length in metres

Ø 60/100 horizontal

Ø 45

NONE

From 0 to 2,7

Over 2,7

DIAPHRAGM

Duct length in metres

Ø 60/100 vertical

Ø 45

NONE

From 0 to 1,9

Over 1,9

DIAPHRAGM

Duct length in metres

Ø 80/125 horizontal

Ø 45

NONE

From 0 to 6,8

Over 6,8

DIAPHRAGM

Duct length in metres

Ø 80/125 vertical

Ø 45

NONE

From 0 to 20

Over 20

DIAPHRAGM

*Duct length in metres

Ø 80 horizontal duct with two

bends

Ø 45

NONE

From 0 to 25

Over 25

DIAPHRAGM

*Duct length in metres

Ø 80 vertical duct without

bends

The kit comprises:

2 - Seal (1)

1 - Concentric 90° bend

(2)

1 - Intake/Exh. concentric

pipe Ø60/100 (3)

1 - Internal washer (4)

1 - External washer (5)

DIAPHRAGM

Positioning of double-lip seals. For correct posi-

tioning of the lip seals on elbows and extensions,

follow the order of assembly shown in the figure.

Loading...

Loading...