TECHNICIAN

INSTALLER

USER

11

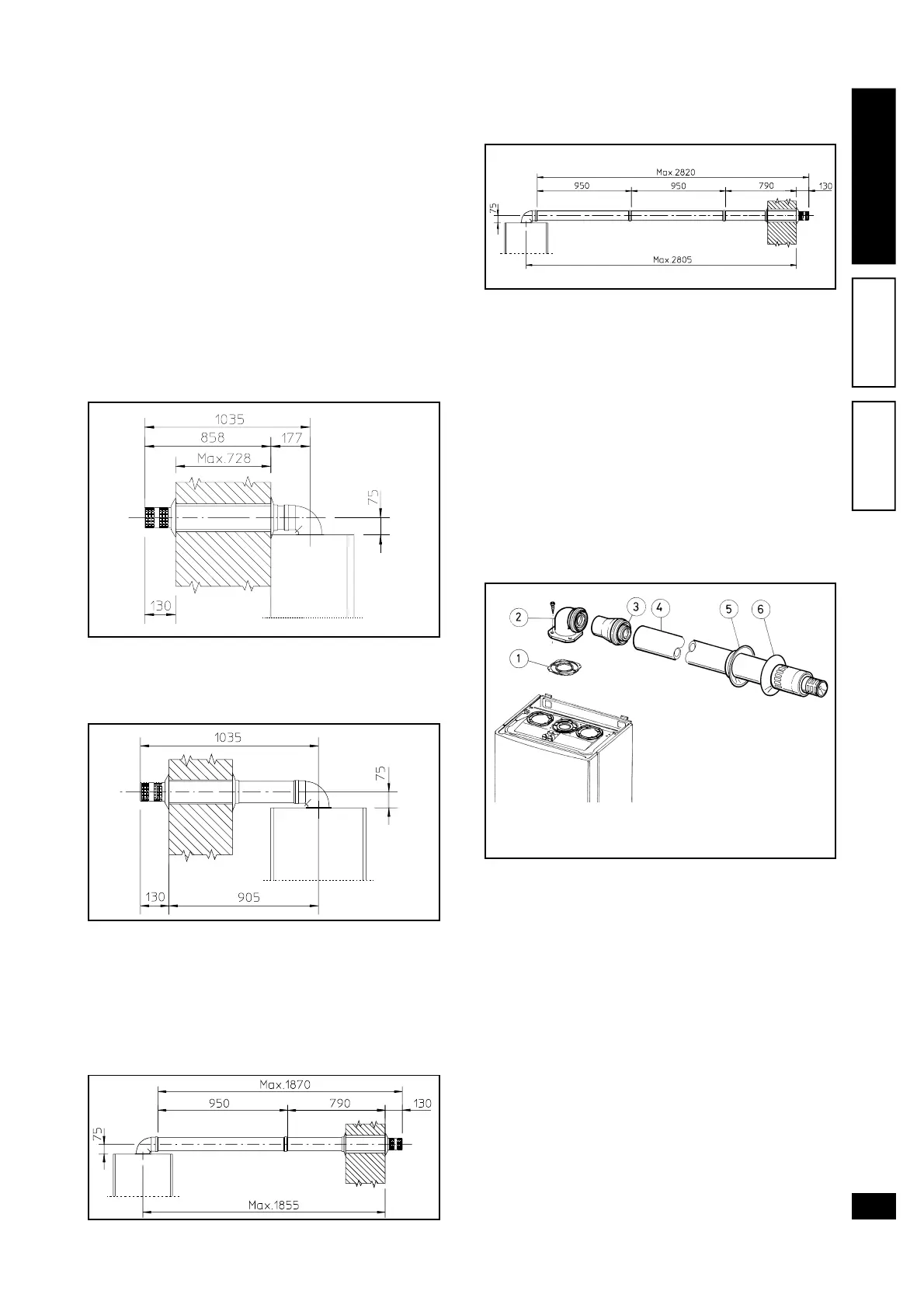

Connection with 1 extension. Max. distance be-

tween vertical boiler axis and external wall: 1855

mm.

Connection with 2 extensions. Max. distance be-

tween vertical boiler axis and external wall 2805.

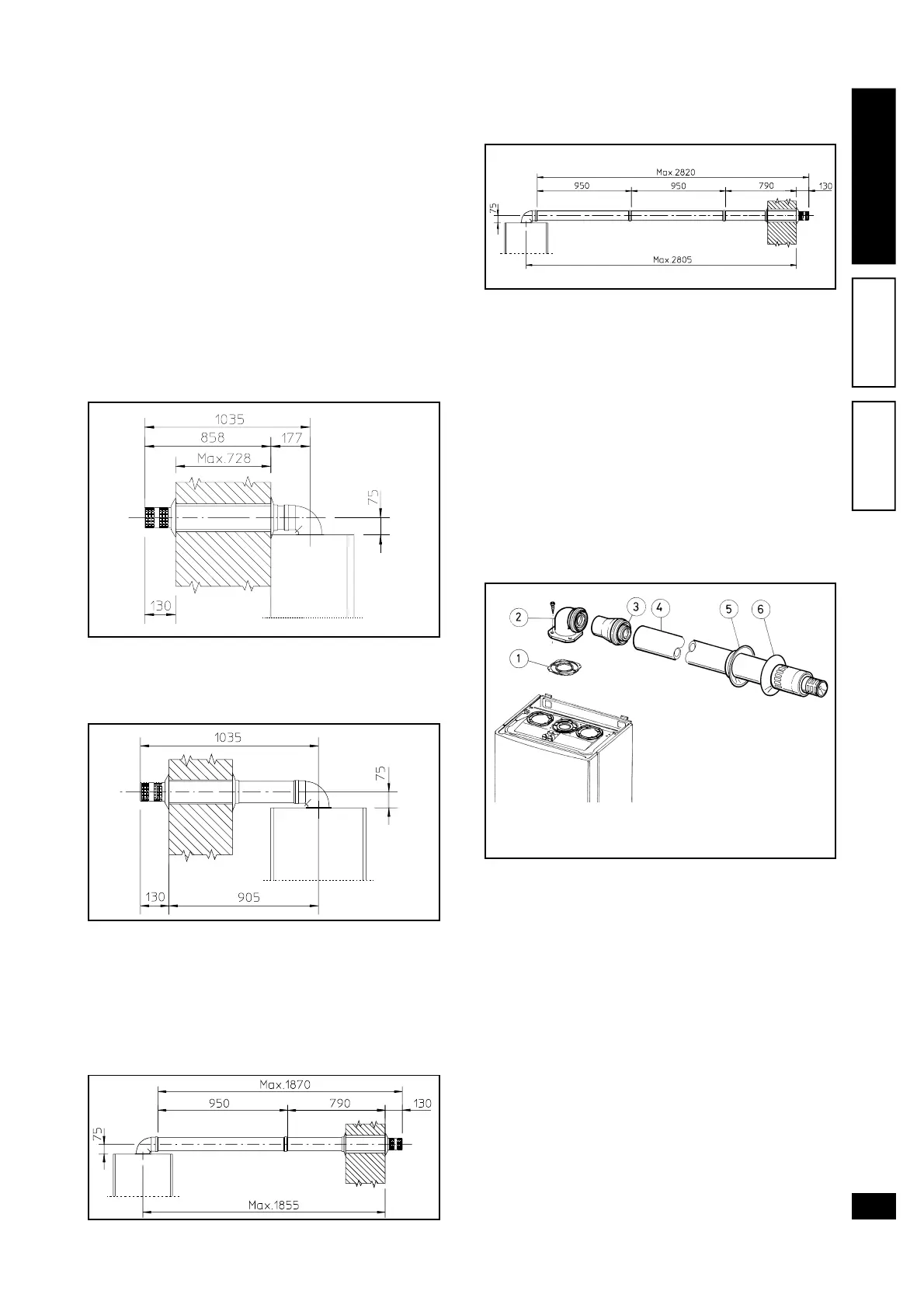

Horizontal intake-exhaust kit Ø 80/125. Kit assem-

bly: install the bend with flange (2) on the central

hole of the boiler taking care to insert the seal (1)

and tighten with the screws supplied in the kit. Fit

the adapter (3) with the male section (smooth) in the

female section of the bend (2) (with lip seal) to the

end stop. Fit the concentric terminal Ø 80/125 (4)

with the male section (smooth) in the female section

of the adapter (3) (with lip seal) to the end stop, en-

suring that the internal and external washers are fit-

ted to ensure sealing efficiency of all couplings.

• Snap fit extension pipe fittings and concentric el-

bows Ø 80/125. To install snap-fit extensions with

other elements of the boiler assembly, proceed as

follows: fit the concentric pipe or elbow with the

male section (smooth) on the female section (with

lip seal) to the end stop on the previously installed

to ensure sealing efficiency of the coupling.

Caution: if the exhaust terminal and/or extension

concentric pipe needs shortening, consider that the

internal duct must always protrude by 5 mm with re-

spect to the external duct.

Normally the horizontal intake/exhaust kit Ø 80/125

is used in the event of using particularly long exten-

sions; the kit Ø 80/125 can be installed with a rear,

right-hand, left-hand or front outlet.

• Extensions for horizontal kit. The horizontal intake/

exhaust kit Ø 80/125 can be extended up to a

couplings on other flue extraction components, pro-

ceed as follows: fit the concentric pipe or concen-

tric elbow with the male section (smooth) on the

female section (with lip-seal) of the previously in-

stalled component to the end stop to ensure per-

fect sealing of the coupling.

The horizontal intake-exhaust kit Ø 60/100 can be

installed with a rear, right-hand, left-hand, or front

outlet as required.

• Application with rear outlet. The 970 mm pipe length

enables partial routing through a maximum thick-

ness 728 mm. Normally the terminal should be

shortened. Calculate the distance by adding the

following: Part thickness + internal protrusion + ex-

ternal protrusion. Minimum protrusion values are

given in the figure below.

• Application with lateral outlet; using the horizontal

intake-exhaust kit only, without the special

extensions, enables routing through a wall

thickness of 905 mm.

• Extensions for horizontal kit. The horizontal intake-

exhaust kit Ø 60/100 can be extended up to a max.

horizontal distance of 3000 mm including the grille

terminal and excluding the concentric bend on out-

put of the boiler. This configuration corresponds to

a resistance factor of 100. In this case special ex-

tensions must be requested.

The kit comprises:

2 - seal (1)

1 - Concentric bend

Ø 60/100 (2)

1 - Adapter Ø 60/100 for Ø

80/125 (3)

1 - Concentric Int./Exh.

bend Ø 80/125 (4)

1 - Internal washer (5)

1 - External washer (6)

Loading...

Loading...