INSTALLER

USER

TECHNICIAN

12

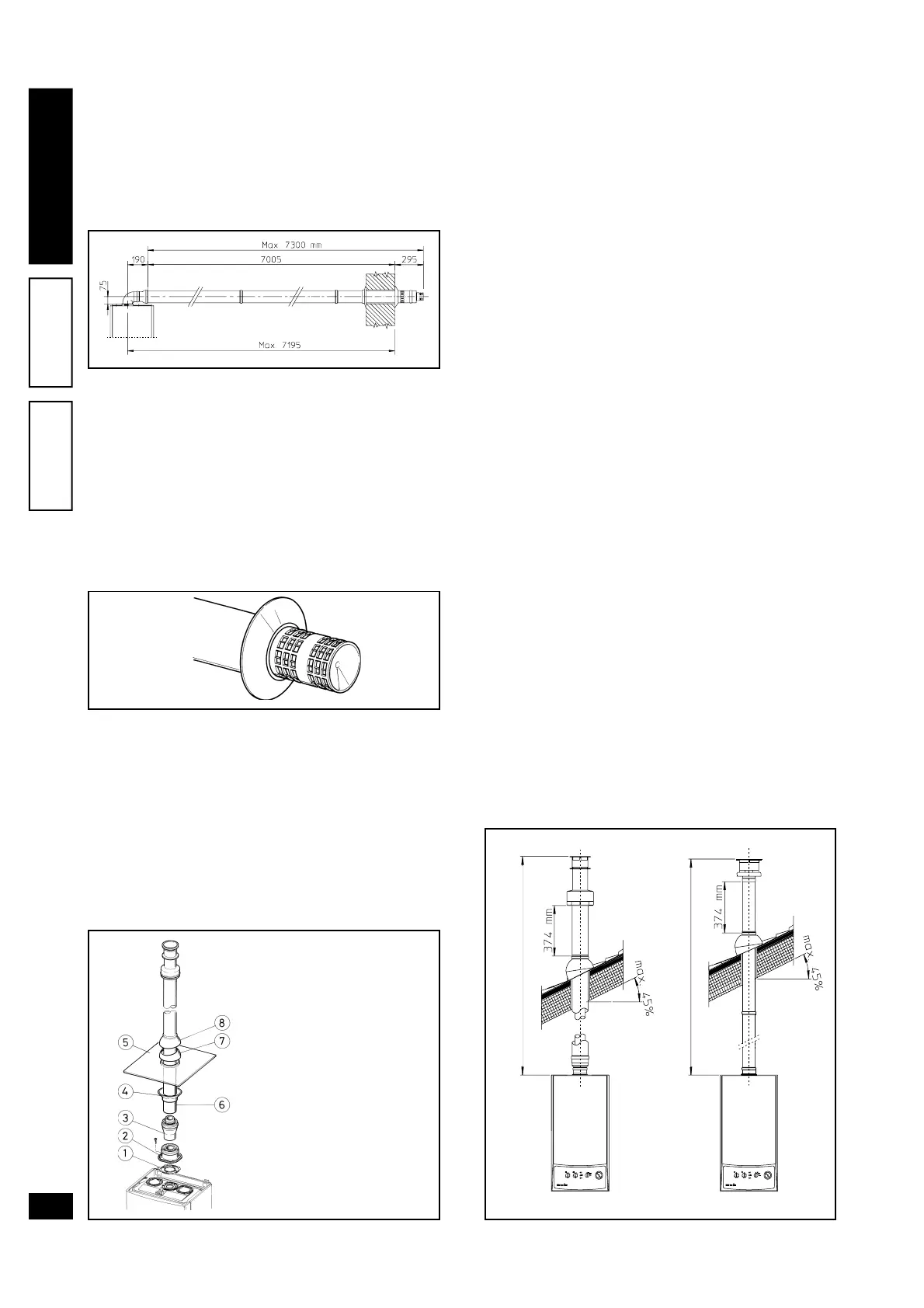

maximum horizontal length of 7300 mm including

the terminal grille and excluding the concentric

bend on output of the boiler and the adapter Ø 60/

100 in Ø 80/125 (see figure page 12). This con-

figuration corresponds to a resistance factor of

100. In these cases specific extensions must be

requested.

N.W.: when installing the ducts, a section clamp

with pin must be installed every 3 metres.

• External grille. The intake/exhaust terminal mod-

els Ø 60/100 and Ø 80/125, if correctly installed,

blend with external building aesthetics. Ensure that

the silicon washer is fitted snugly against the ex-

ternal wall.

N.W.: for safety purposes, do not totally or partially

obstruct the boiler intake/exhaust terminal even

temporarily.

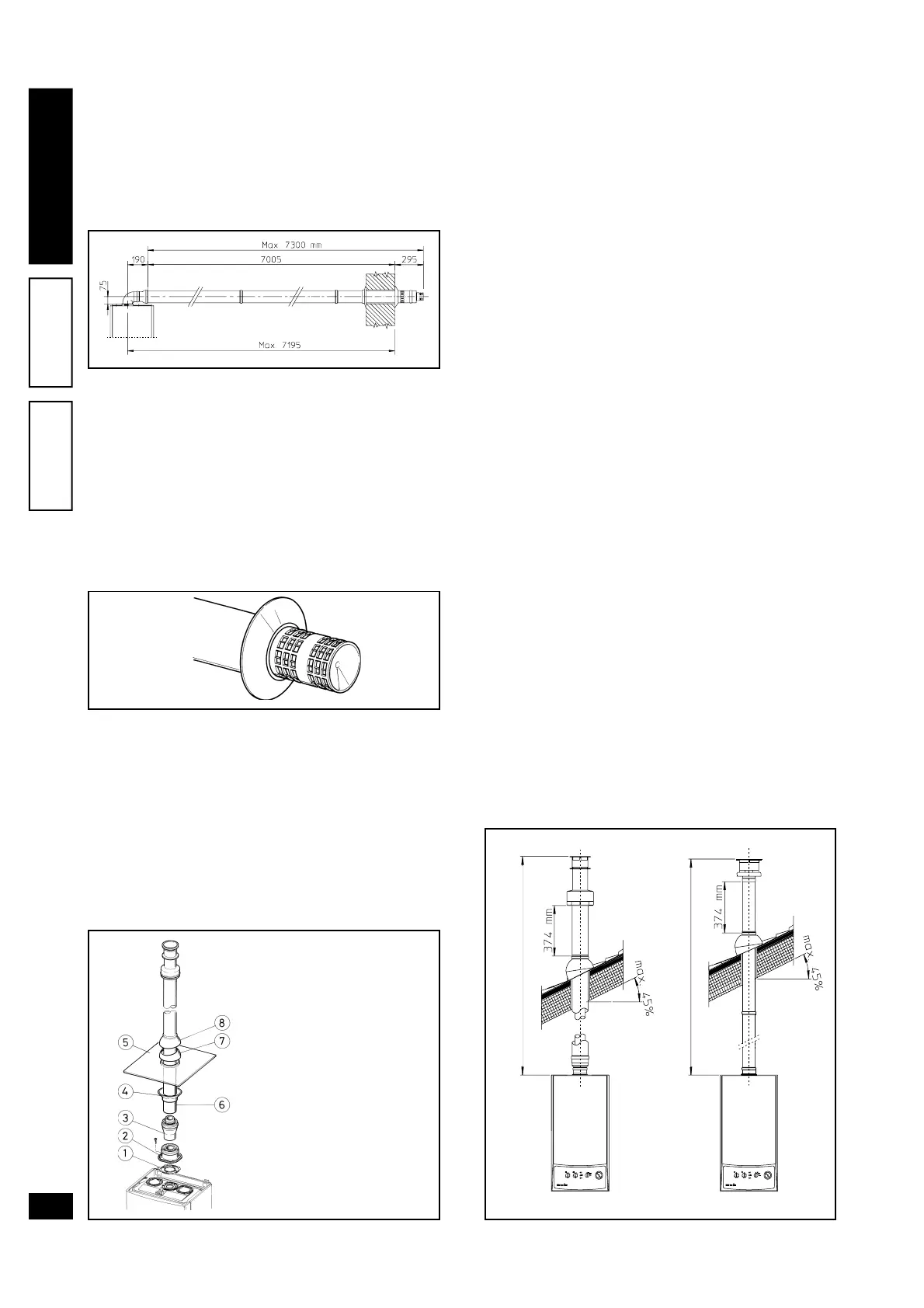

Vertical kit with aluminium tile Ø 80/125. Kit as-

sembly: install the concentric flange (2) on the cen-

tral hole of the boiler taking care to insert the seal (1)

supplied with the kit and tighten by means of the

screws supplied with the boiler. Fit the male section

(smooth) of the adapter (3) coin the female section

of the concentric flange (2). Installing the imitation

aluminium tile. Replace the tile with the aluminium

sheet (5), shaping it to ensure off-flow of rainwater.

Position the fixed half-shell (7) on the aluminium tile

and insert the intake/exhaust pipe (6). Fit the con-

centric terminal Ø 80/125 with the male section (6)

(smooth), in the female section of the adapter (3)

(with lip seal) to the end stop, ensuring that washer

(4) si already fitted to ensure sealing efficiency of all

couplings.

• Snap fit extension pipe fittings and concentric el-

bows Ø 80/125. To install snap-fit extensions with

other elements of the boiler assembly, proceed as

follows: fit the concentric pipe or elbow with the

male section (smooth) on the female section (with

lip seal) to the end stop on the previously installed

to ensure sealing efficiency of the couplings.

Caution: if the exhaust terminal and/or extension

concentric pipe needs shortening, consider that the

internal duct must always protrude by 5 mm with re-

spect to the external duct.

This specific terminal enables flue exhaust and air

intake in a vertical direction.

N.W.: the vertical kit Ø 80/125 with aluminium tile

enables installation on terraces and roofs with maxi-

mum gradient of 45% (24°) and the height between

the terminal cap and half-shell (374 mm) must be

strictly observed.

This vertical kit configuration can be extended to a

maximum length of 12200 mm in a vertical straight

route, including the terminal (see figure below). This

configuration corresponds to a resistance factor of

100. In this case specific extensions must be re-

quested.

Terminal Ø 60/100 can also be used for vertical ex-

haust, in conjunction with concentric flange code no.

3.011141 (sold separately). height between the ter-

minal cap and half-shell (374 mm) must be strictly

observed (see drawing below).

This vertical kit configuration can be extended to a

maximum length of 4700 mm in a vertical straight

line, including the terminal (see figure below).

MAX. LENGTH 4700 mm

MAX. LENGTH 12200 mm

The kit comprises:

2 - Seal (1)

1 - Female concentric flange

(2)

1 - Adapter Ø 60/100 for Ø

80/125 (3)

1 - Washer(4)

1 - Aluminium tile (5)

1 - Int./Exh. concentric pipe

Ø 80/125 (6)

1 - Fixed half-shell (7)

1 - Mobile half-shell (8)

Loading...

Loading...