a

1

2

d

e

4

b

c

3

5

12

INSTALLER

USER

MAINTENANCE TECHNICIAN

TECHNICAL DATA

1.7 Hydraulic connection.

In order not to void the heat primary exchanger

warranty, before making the boiler connections,

carefully clean the heating system (pipes, radiators,

etc.) with special pickling or de-scaling products to

remove any deposits that could compromise correct

boiler operation.

A treatment of the heating and water system water is required,

in compliance with the technical standards in force, in order to

protect the system and the appliance from deposits (e.g. scale),

slurry or other hazardous deposits.

Hydraulic connections must be made in a rational way using the

couplings on the boiler template.

ATTENTION:

the manufacturer declines all liability

in the event of damage caused by the

installation of an automatic lling system.

In order to meet the system requirements established by EN 1717

in terms of pollution of drinking water, we recommend installing

the IMMERGAS anti-backow kit to be used upstream of the cold

water inlet connection of the boiler. We also recommend using a

category 2 heat transfer uid (ex: water + glycol) in the boiler's pri-

mary circuit (C.H. circuit), as dened in standard EN 1717.

To preserve the duration of appliance eciency fea-

tures, in the presence of water whose features can

lead to the deposit of lime scale, installation of the

“polyphosphate dispenser” kit is recommended .

3 bar safety valve.

Safety valve discharge must always be conveyed through a draining

funnel. Otherwise, the manufacturer declines any responsibility

in case of ooding if the drain valve cuts in.

1.8 Electrical connection.

e appliance has an IPX5D protection degree; electrical safety of

the appliance is achieved only when it is connected properly to an

ecient earthing system, as specied by current safety standards.

ATTENTION:

the manufacturer declines any respon-

sibility for damage or physical injury

caused by failure to connect the boiler

to an ecient earth system or failure to

comply with the reference standards.

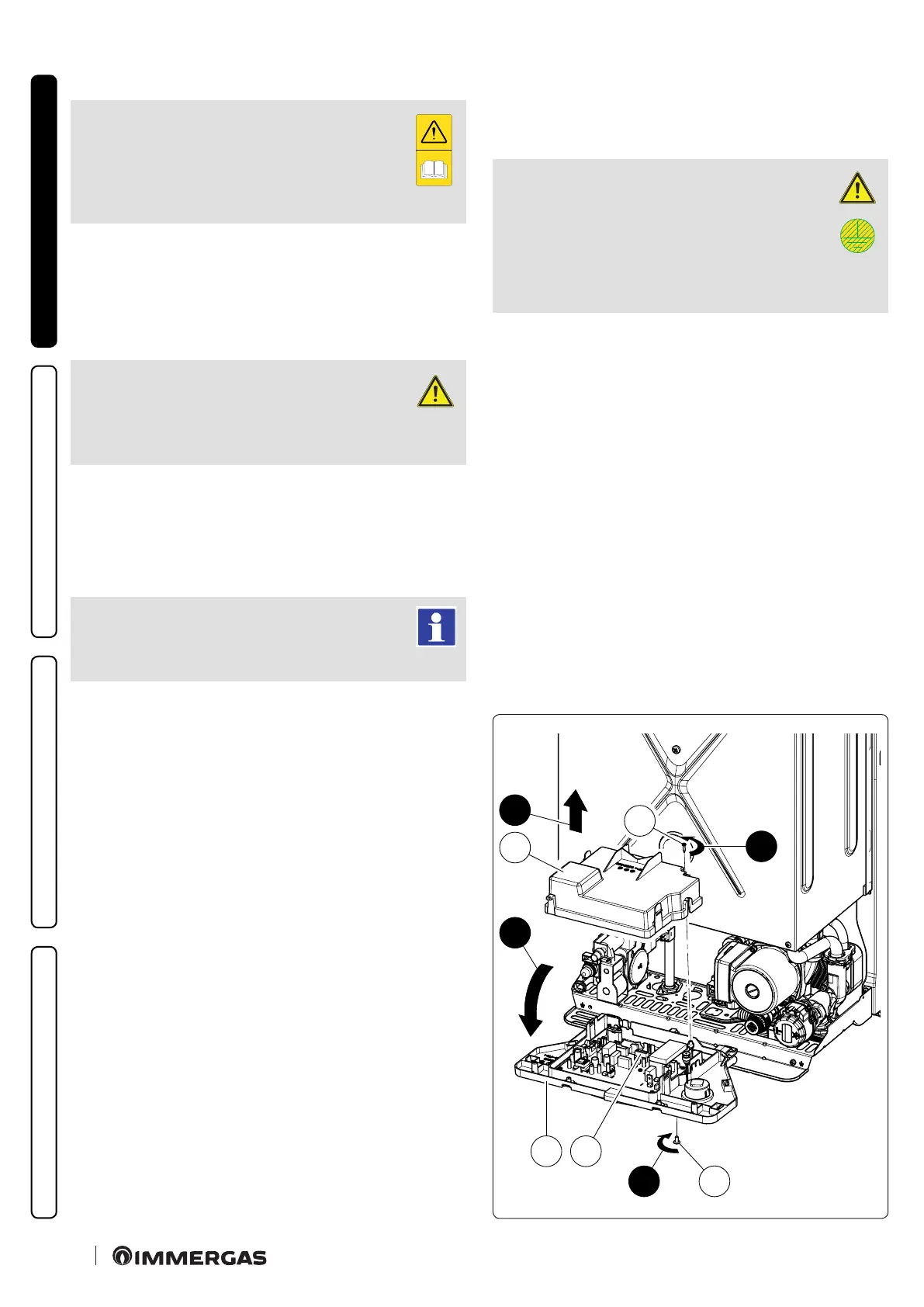

Open the control panel connections compartment (Fig. 5)

To carry out electrical connections, all you have to do is open the

connections compartment as follows.

Remove the casing:

1. Loosen the screw (a) at the bottom.

2. Place the control panel (b) horizontally;

3. Remove the screw (c) securing the control panel (b) cover (d);

4. Remove the cover (d) from the control panel (b);

At this point, it is possible to access the terminal board (e).

Also ensure that the electrical installation corresponds to maxi-

mum absorbed power specications as shown on the boiler data

nameplate.

Boilers are supplied complete with an “X” type power cable without

plug.

Loading...

Loading...