31

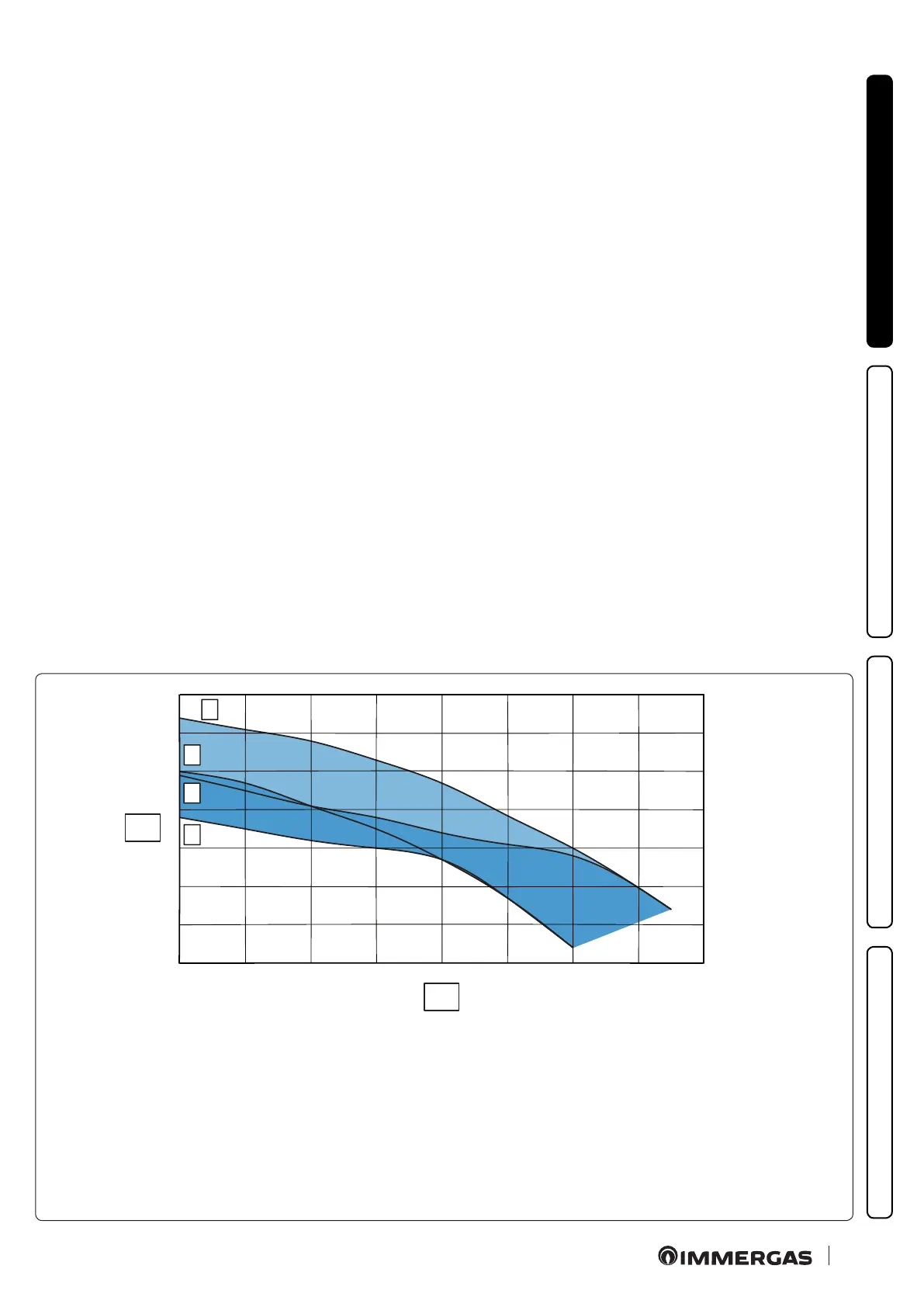

0 200 400 600 800 1000 1200 1400 1600

Y1

20

40

60

10

30

50

0

20

40

60

10

30

50

0

1

2

3

4

27

INSTALLER

USER

MAINTENANCE TECHNICIAN

TECHNICAL DATA

1.22 Circulation pump.

e boilers are supplied with a built-in circulation pump with

three-position electric speed control. e boiler does not oper-

ate correctly with the circulation pump on rst speed. To ensure

optimal boiler operation, in the case of new systems (single pipe

and module) it is recommended to use the pump at maximum

speed. e circulation pump is already tted with a condenser.

Pump release. If, aer a prolonged period of inactivity, the circu-

lation pump is blocked, unscrew the front cap and turn the motor

sha using a screwdriver. Take great care during this operation to

avoid damage to the motor.

By-pass adjustment (Part. 25 Fig. 32). If necessary, the by-

pass can be adjusted according to system requirements from a

minimum (by-pass excluded) to a maximum (by-pass inserted)

represented by the graph (Fig. 31). Make the adjustment using a

at head screwdriver, turn clockwise and insert the by-pass; by

turning it anti-clockwise it is excluded.

Head available to the system.

1.23 Kits available on request.

• System shut o valves kit. e boiler is designed for installation

of system interception cocks to be placed on ow and return

pipes of the connection assembly. is kit is particularly useful

for maintenance as it allows the boiler to be drained separately

without having to empty the entire system.

• Polyphosphate dispenser kit. e polyphosphate dispenser re-

duces the formation of lime-scale and preserves the original heat

exchange and domestic hot water production conditions. e

boiler is prepared for application of the polyphosphate dispenser

kit.

• Cover kit. For outdoor installations, in partially protected areas

and with direct air intake, the top protection cover must be tted

for a correct functioning of the boiler and to protect it from

storms (Fig. 9). For indoor installations, type B conguration, a

suitable top protection cover coupled with the ue exhaust kit

must be tted.

• Anti freeze kit with resistance (on request). If the boiler is in-

stalled in a place where the temperature falls below -5°C and in

the event there is no gas, the appliance can freeze. To prevent

freezing of the domestic hot water system, an anti freeze kit with

an electrical resistance can be tted from the relative cable and

from a control thermostat.

e above-mentioned kits are supplied complete with instructions

for assembly and use. Check the complete list of kits available and

which can be combined with the product, consult the Immergas

website, the Immergas Price List or the technical-commercial

documentation (catalogues and data sheets).

Key:

1 = Head available to the system at speed 3 with by-pass closed

2 = Head available to the system at speed 3 with by-pass open

3 = Head available to the system at speed 2 with by-pass closed

4 = Head available to the system at speed 2 with by-pass open

Area between curves 1 and 3 = Available system head with by-pass closed

Area between curves 2 and 4 = Available system head with by-pass open

X1 = Flow rate (l/h)

Y1 = Head (kPa)

Loading...

Loading...