31

3-4

3-5

3-6

2

3 4

3 4

1

2

3 4

2

1

INSTALLERUSER

MAINTENANCE TECHNICIAN

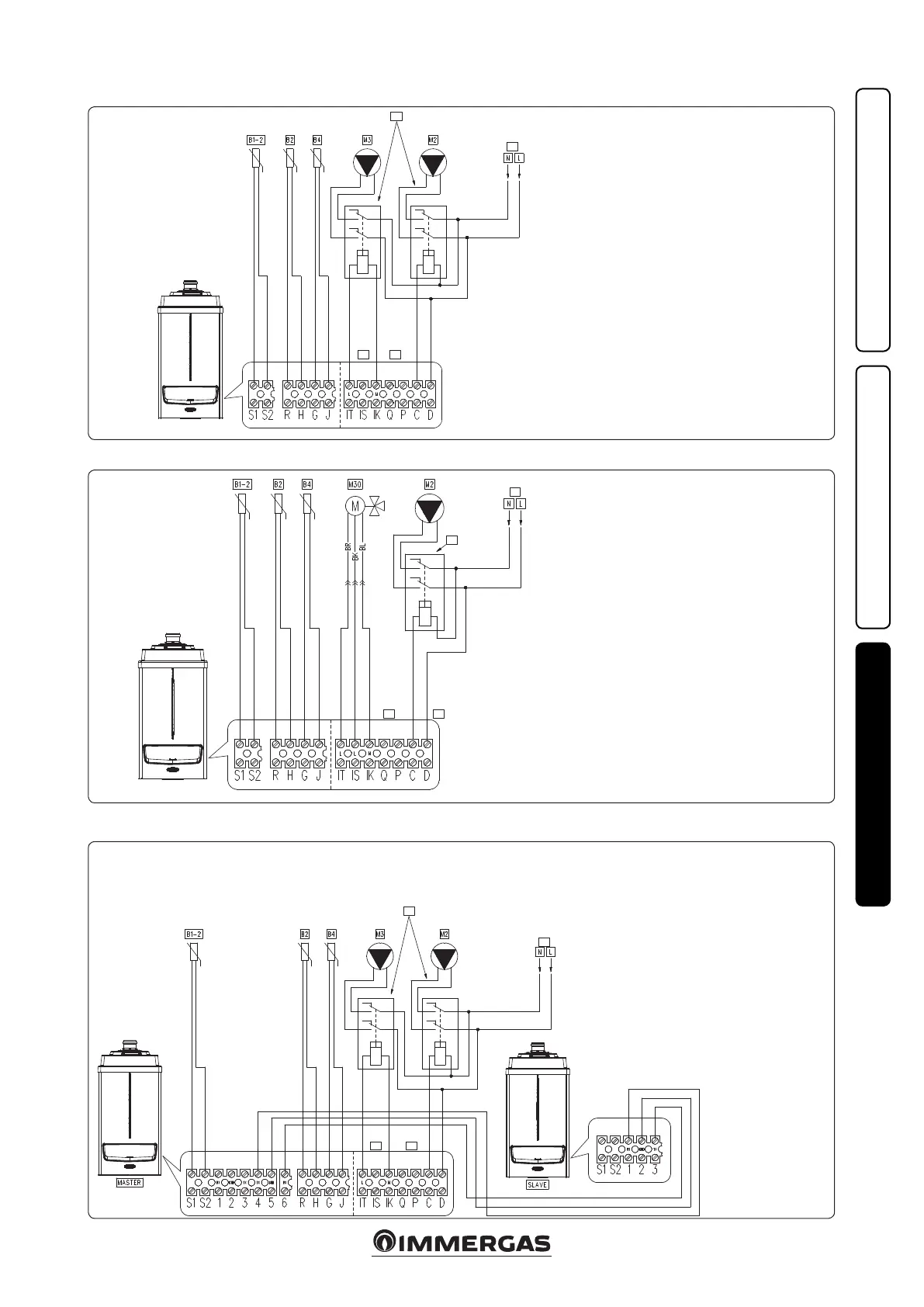

3.4 D.H.W. PUMP BOILER AND TANK PROBE WIRING DIAGRAM.

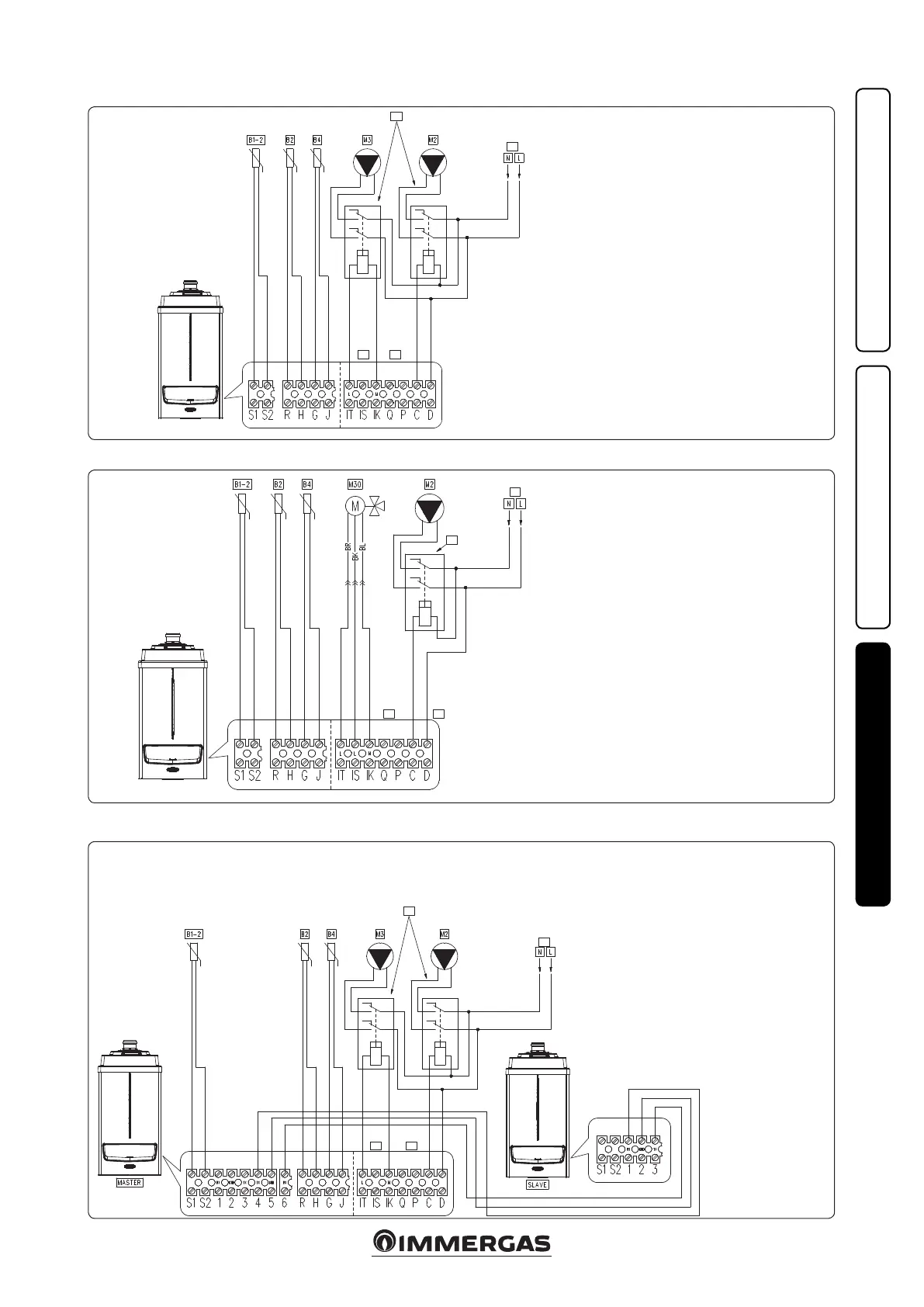

3.5 COMMON FLOW PROBE AND 3WAY BOILER WIRING DIAGRAM.

3.6 SIMPLE CASCADE BOILER WITH D.H.W. PUMP AND TANK PROBE WIRING DIAGRAM.

Key:

B1-2 -System ow probe (NTC)

B2 - Domestic hot water probe (NTC)

B4 - External probe

M2 - Plant CH pump

M3 - Domestic hot water pump

Note (probe B1-2, B2, B4):

- Connection cable diameter 3÷7 mm

- Cable section 0.5 ÷ 1.5 mm

2

1 - External relay (optional)

2 - 230 Vac 50 Hz

3 - “IT”-“IK” outlet =

230 Vac - 0,8 A Max. cosφ ≥ 0,6

4 - “C”-“D” inlet = Clean contact

Max. 230 Vac - 0,8 A Max. cosφ ≥ 0,6

Key:

B1-2 - System ow probe (NTC)

B2 - Domestic hot water probe (NTC)

B4 - External probe

M2 - Plant CH pump

M30 - 3-way valve

Note (probe B1-2, B2, B4):

- Connection cable diameter 3÷7 mm

- Cable section 0.5 ÷ 1.5 mm

2

1 - External relay (optional)

2 - 230 Vac 50 Hz

3 - “IT”-“IS"-"IK” outlet =

230 Vac - 0,8 A Max. cosφ ≥ 0,6

4 - “C”-“D” inlet = Clean contact

Max. 230 Vac - 0,8 A Max. cosφ ≥ 0,6

Key:

B1-2 - System ow probe (NTC)

B2 - Domestic hot water probe (NTC)

B4 - External probe

M2 - Plant CH pump

M3 - Domestic hot water pump

Note (Connection bus):

- Connection cable diameter 3÷7 mm

- Cable section 0.5 ÷ 1.5 mm

2

- Maximum length 3 m

Note: Probes B1-2, B2, B4 must be connected

to the MASTER boiler.

Note (probe B1-2, B2, B4):

- Connection cable diameter 3 ÷ 7 mm

- Cable section 0.5 ÷ 1.5 mm

2

1 - External relay (optional)

2 - 230 Vac 50 Hz

3 - “IT”-“IK” outlet =

230 Vac - 0,8 A Max. cosφ ≥ 0,6

4 - “C”-“D” inlet = Clean contact

Max. 230 Vac - 0,8 A Max. cosφ ≥ 0,6

Loading...

Loading...