14

13

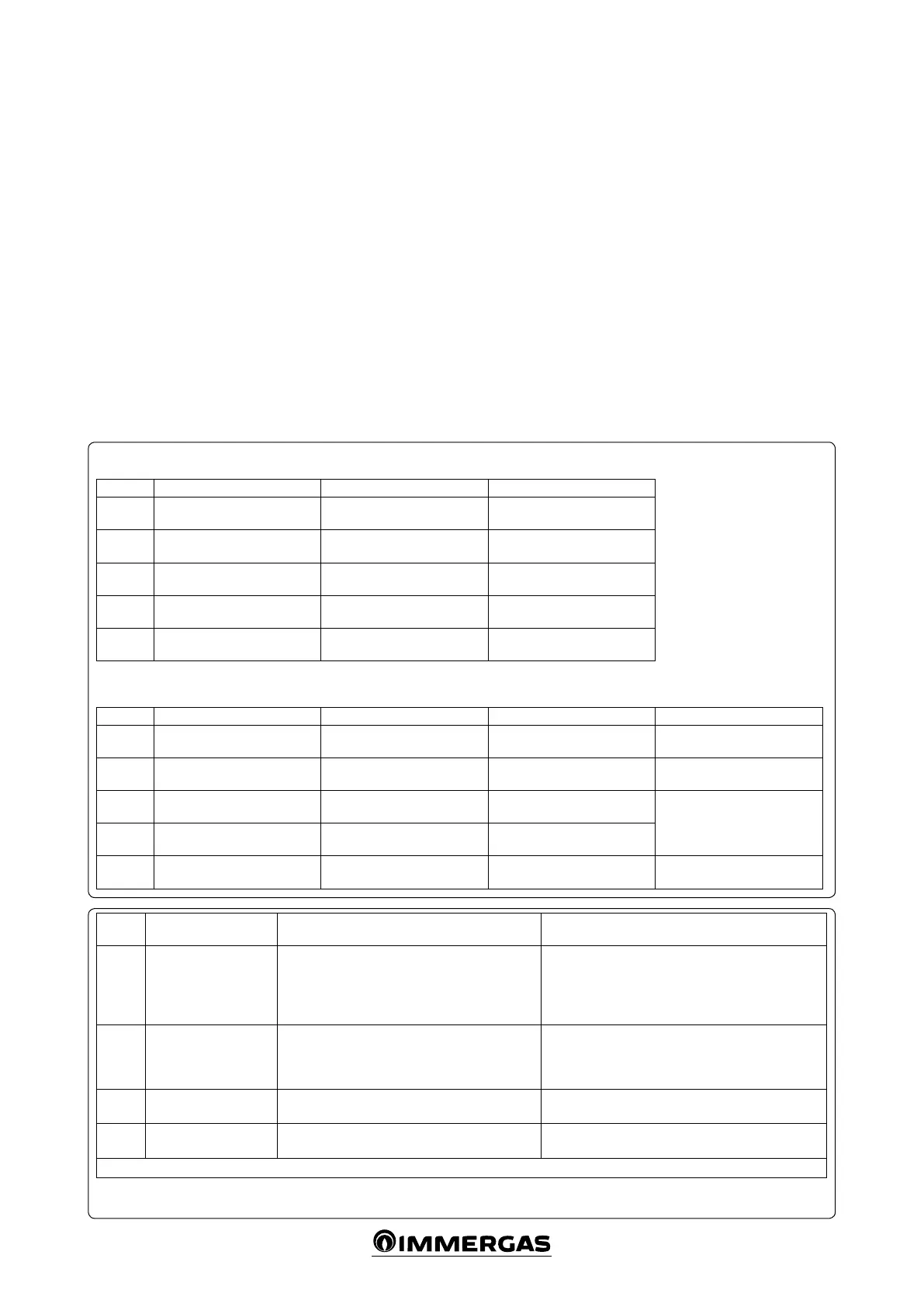

e system operating status is indicated by LEDs

(Ref. 10 Fig. 12 ) according to the relative tables

(Fig. 13).

FAULT AND ANOMALY SIGNALS.

e P.C.B. reports a fault by means of a code

shown on the remote control display, according

to the table below and the table in the boiler

instruction booklet. Depending on the settings

of the relevant parameters, it is possible to decide

on which remote control the fault is displayed

(Par. “Programming the P.C.B.”).

System with 1 high temperature zone and 1 low temperature zone.

LED O On Slow Flashing Fast Flashing

DL1

(Red)

No remote control communica-

tion in OT-S1

Remote control presence in

OT-S1

Zone 1 active request Open safety thermostat

DL2

(Red)

Operation with Room er-

mostat

Remote control presence in

OT-S2

Zone 2 active request /

DL3

(Red)

Mixing valve stopped Mixing valve opening /

Low temperature zone probe

anomaly

(simultaneous ashing)

DL4

(Red)

Mixing valve stopped Mixing valve closing /

DL5

(Green)

No communication with boiler

Communication with boiler in

progress

DHW request in progress /

System with high temperature zones

LED O On Slow Flashing

DL1

(Red)

No remote control communica-

tion in OT-S1

Remote control 1 presence Zone 1 active request

DL2

(Red)

Operation with TA2 Remote control 2 presence Zone 2 active request

DL3

(Red)

Operation with TA3 Remote control 3 presence Zone 3 active request

DL4

(Red)

Operation with TA4 Remote control 4 presence Zone 4 active request

DL5

(Green)

No communication with boiler

Communication with boiler in

progress

Boiler in domestic hot water

operating mode

Perform the electrical connection as required and

as shown in the following wiring diagrams (Par.

“Wiring diagrams”).

SYSTEM USE.

- DHW temperature setting. e domestic hot

water temperature is controlled by the “master”

remote control, i.e. the one connected to the

OT-S1 channel of the kit connected to the boil-

er. e settings made on the remaining remote

controls for domestic hot water are ignored.

- Flow temperature setting. The boiler flow

temperature for central heating can be ad-

justed on each remote control as required. Or

in the case of a system controlled from room

thermostats, the ow temperature is set on the

relative parameters (Par. “Programming the

P.C.B.”). e system takes into consideration

the highest temperature in order to meet all

the active requests.

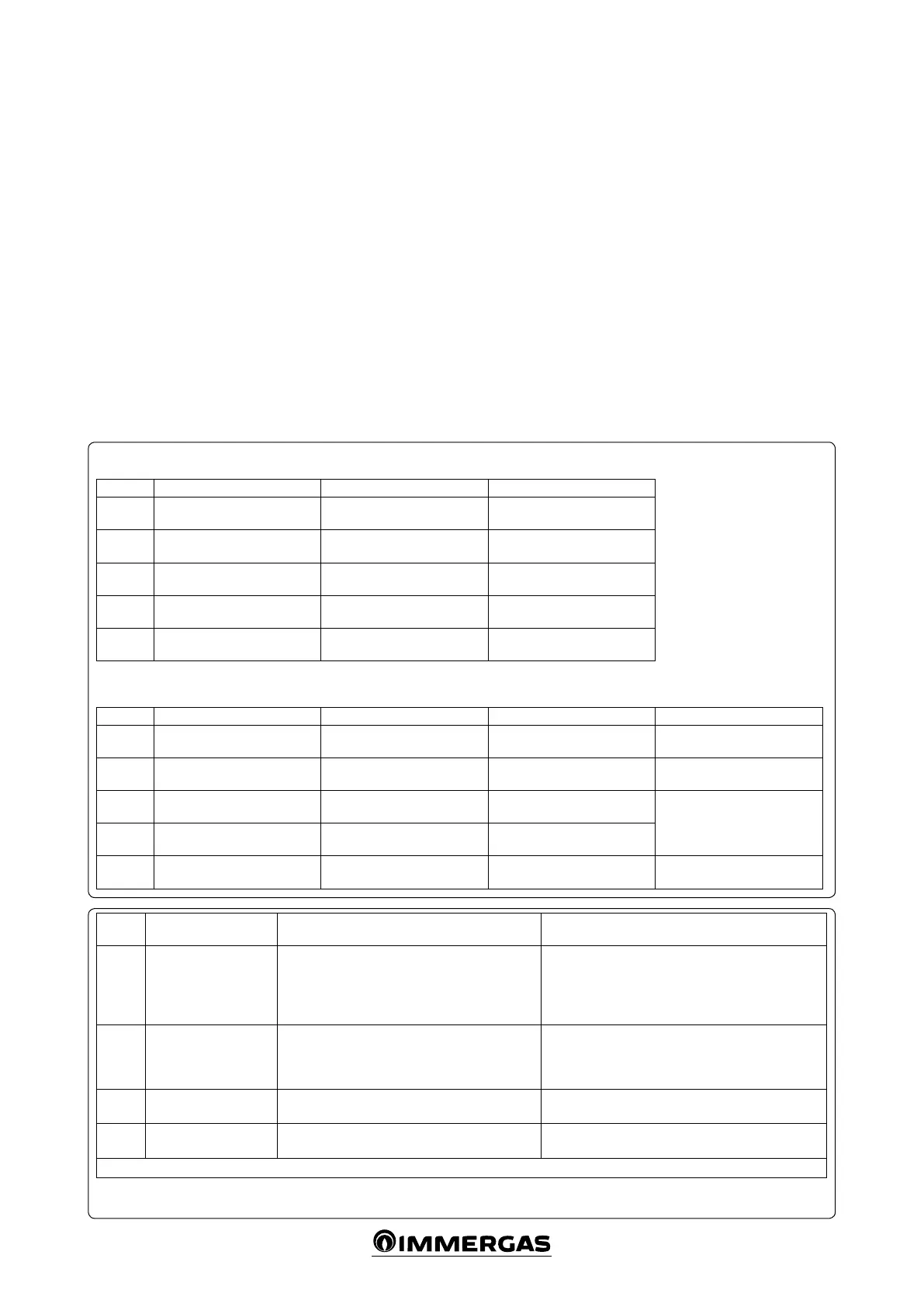

Error

Code

Anomaly signalled Cause Boiler status / Solution

36

IMG Bus communica-

tion loss

Communication between the components is inter-

rupted due to a fault on the boiler, multi-zone kit

or IMG Bus.

Disconnect and reconnect the power to the boiler. If the

Remote Control is still not detected on re-starting, the

boiler will switch to local operating mode, i.e. using the

controls on the control panel. In this case, the boiler

will not meet the heating requests (1)

68

Communication

failure between remote

control and multi-zone

kit

Due to a fault, communication between remote

control and multi-zone kit is interrupted.

Check the connection between the devices. In this case,

the boiler will meet the heating requests according to

the settings of the “Emergency Function” parameters

(1)

46

System protection

thermostat fault

e board detects a fault on the system protection

thermostat (optional).

e requests of the mixed zone (low temperature) are

not met (1)

55

Low temperature zone

probe anomaly

e board detects a fault on the low temperature

probe (optional).

e requests of the mixed zone (low temperature) are

not met (1)

(1) If the block or anomaly persists, contact an authorised company (e.g. Immergas Technical Aer-Sales Service).

ELECTRICAL CONNECTION.

e kit has an IP20 protection rating; electrical

safety of the appliance is achieved only when it

is properly connected to an ecient earthing

system, as specied by current safety standards.

Attention: the manufacturer declines any re-

sponsibility for damage or physical injury caused

by failure to connect the kit to an ecient earth

system or failure to comply with IEC reference

standards.

Important: it is mandatory to prepare two elec-

trical connection lines in order to separate the

electrical power supply from all other low-voltage

connections, according to the standards in force

regarding electrical systems.

e electrical connection between the devices

must be made using cables with a minimum

section of 0.50 mm

2

and with a maximum section

of 2.5 mm

2

; the length of these connections must

not exceed 15 metres.

14

Loading...

Loading...