sales@romanoff.com | www.romanoff.com

4.17 Recommendations for flasks

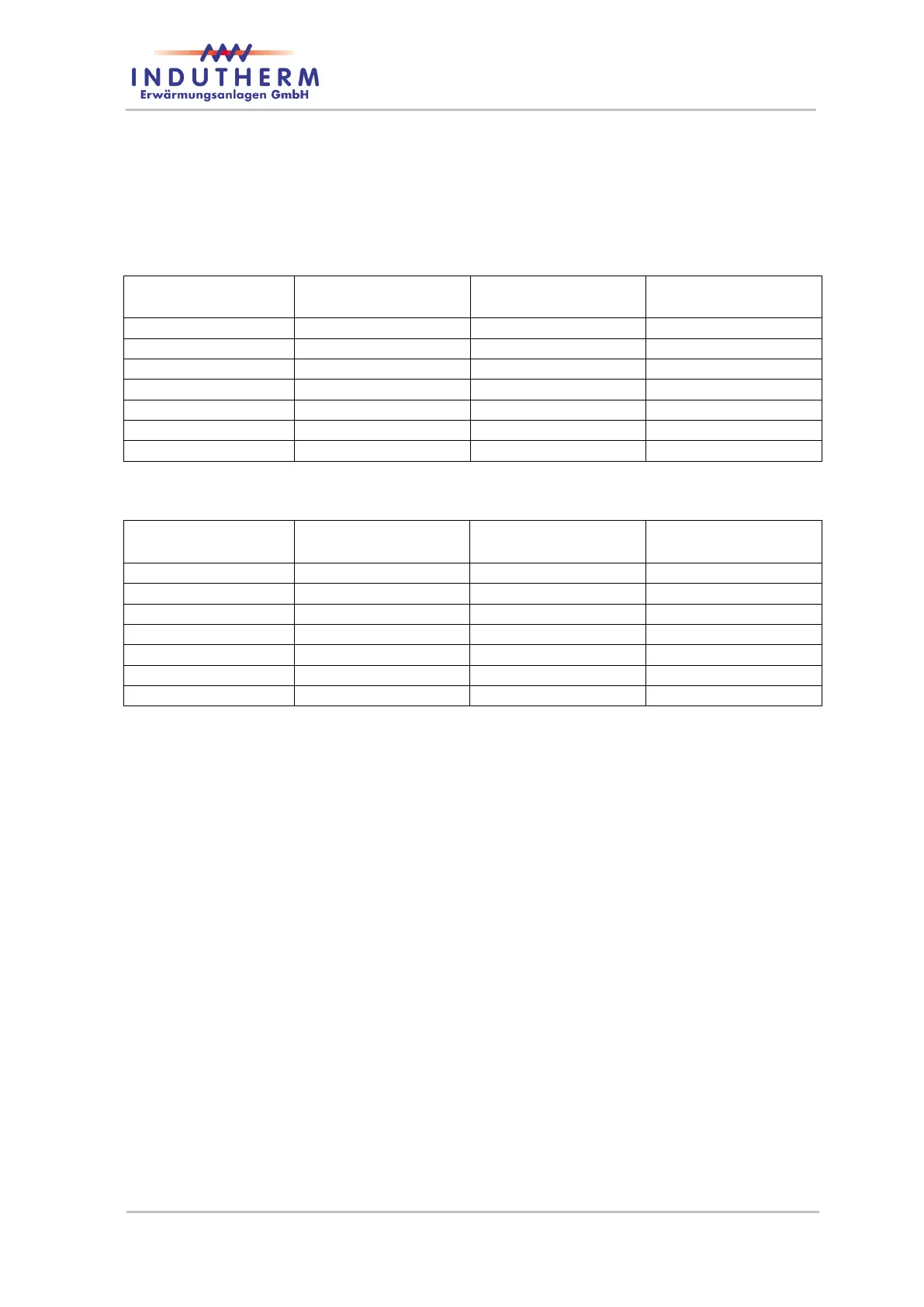

For standard MC60V flasks there are some recommendations:

gypsum bonded investment powder like Goldstar XL, XXX, Kerr Satin Cast 20 etc. 100: 40

powder:water

investment powder

in grams

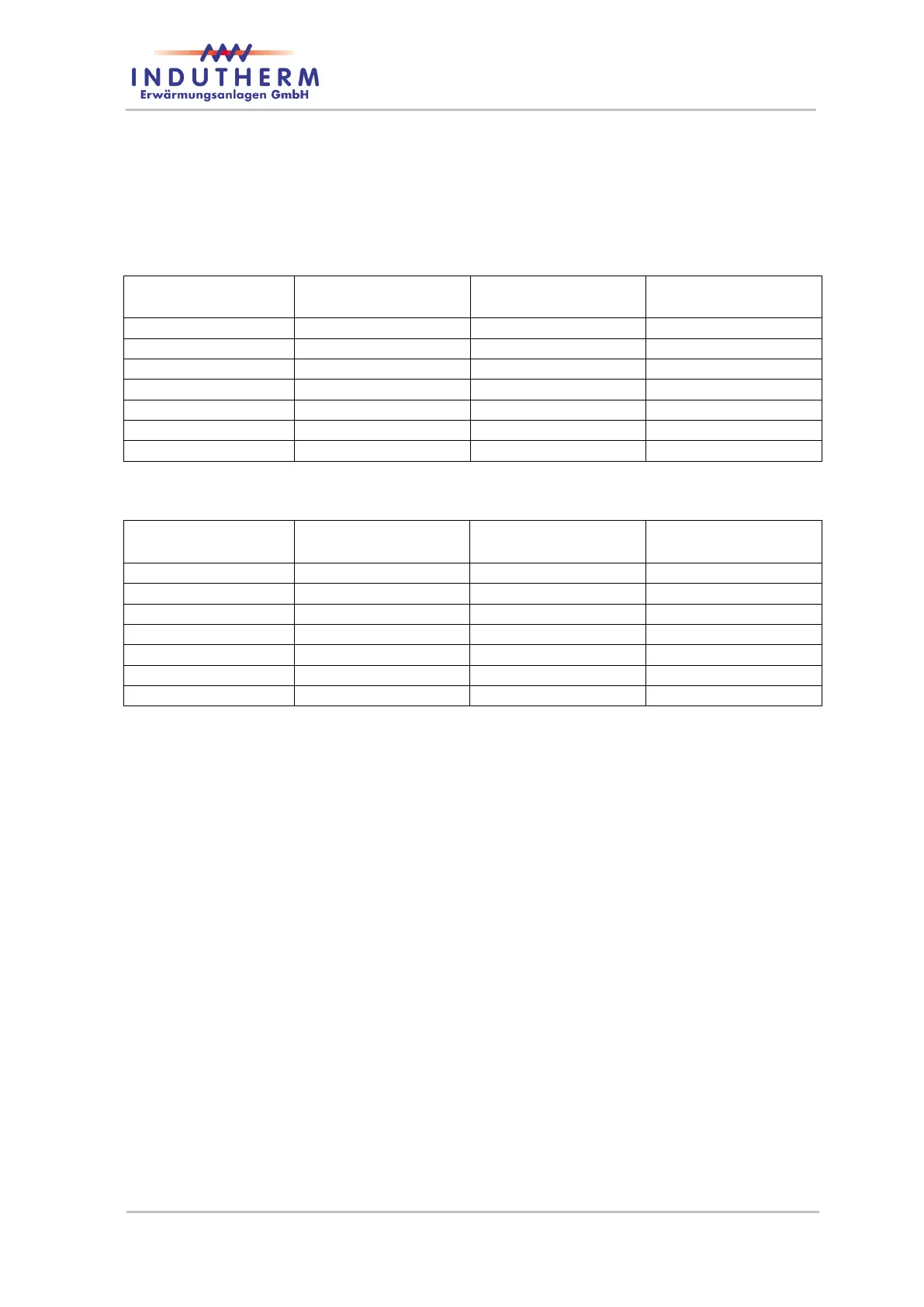

phosphate bonded investment powder like Goldstar Platincast, H.T.

100:35 phosphate: water

investment powder

in grams

4.18 Preheating of the flasks

After investment process the flasks have to undergo a firing process. For this purpose the

flasks have to be placed in the furnace with the button (opening) down to ensure a com-

plete flow-out of wax.

The firing cycle of gypsum bonded flasks has normally 3 phases:

Phase 1. Melting out of wax and steaming out remaining moisture of flasks very

slowly. This steaming out process should be done very gently to prevent gypsum

against cracks. In case of the flasks for MC60V (comparatively small) we recom-

mend to reach a temperature of 300 °C (= ramp of 2.5 °C/min) in 120 minutes. On

bigger flasks, we recommend to go to 150 °C – 180 °C in 120 minutes.

Investment powder is a good insulator, that’s why the heat takes time to reach the

core of the flask. To ensure that the flasks heat up homogeneous, let the flasks

have a rest at the hold temperature of 30 minutes on small flasks and up for 60

minutes on bigger flasks. After this time the wax should be fully flowed out.

Phase 2 Burning process of flasks. This process is like a sintering process: single

particles bake together (bonding) and the investment material becomes much

stronger. Gypsum bonded investment materials need 730 °C for this bonding pro-

cess. To reach this temperature starting at 300 °C, ramp should be 4 °C/min =

process takes around 2 hours. On bigger flasks (starting at 150 °C, we recom-

mend to select ramp 5 °C/min. Duration in the furnace: for small flasks like MC60V

around 1 hour, on bigger flasks up to 5 hours.

Loading...

Loading...