sales@romanoff.com | www.romanoff.com

4.20 Collection of spoiled castings

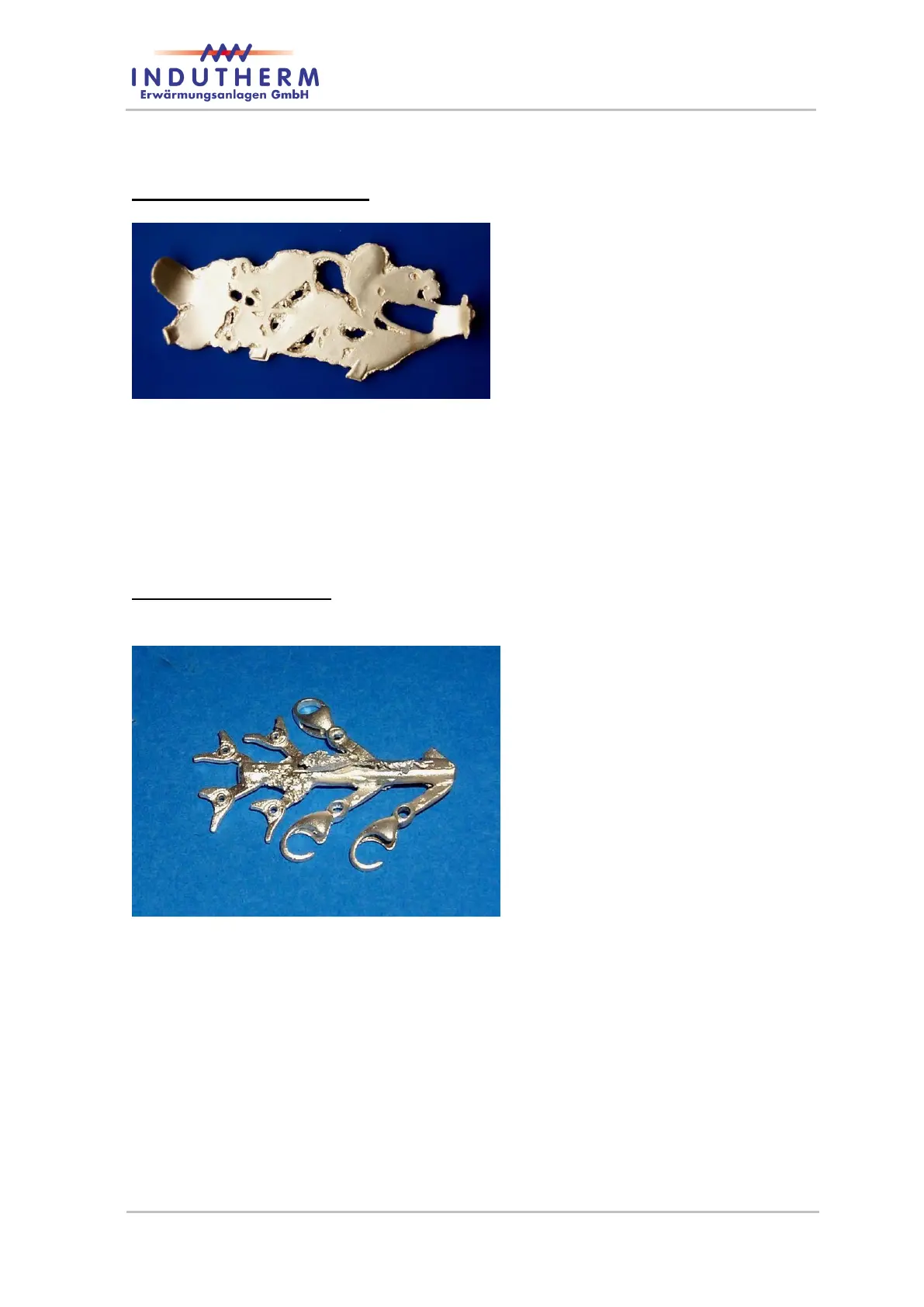

Horizontal flashing or finning

Figure 18: horizontal flashing or finning

Incorrect powder / water ratio (too much

water).

Using correct amount of water (espe-

cially important with vacuum investing

machines).

Work time of investment not used up.

Ensuring the work time is used up and

slurry temperature is 20 – 22 ºC.

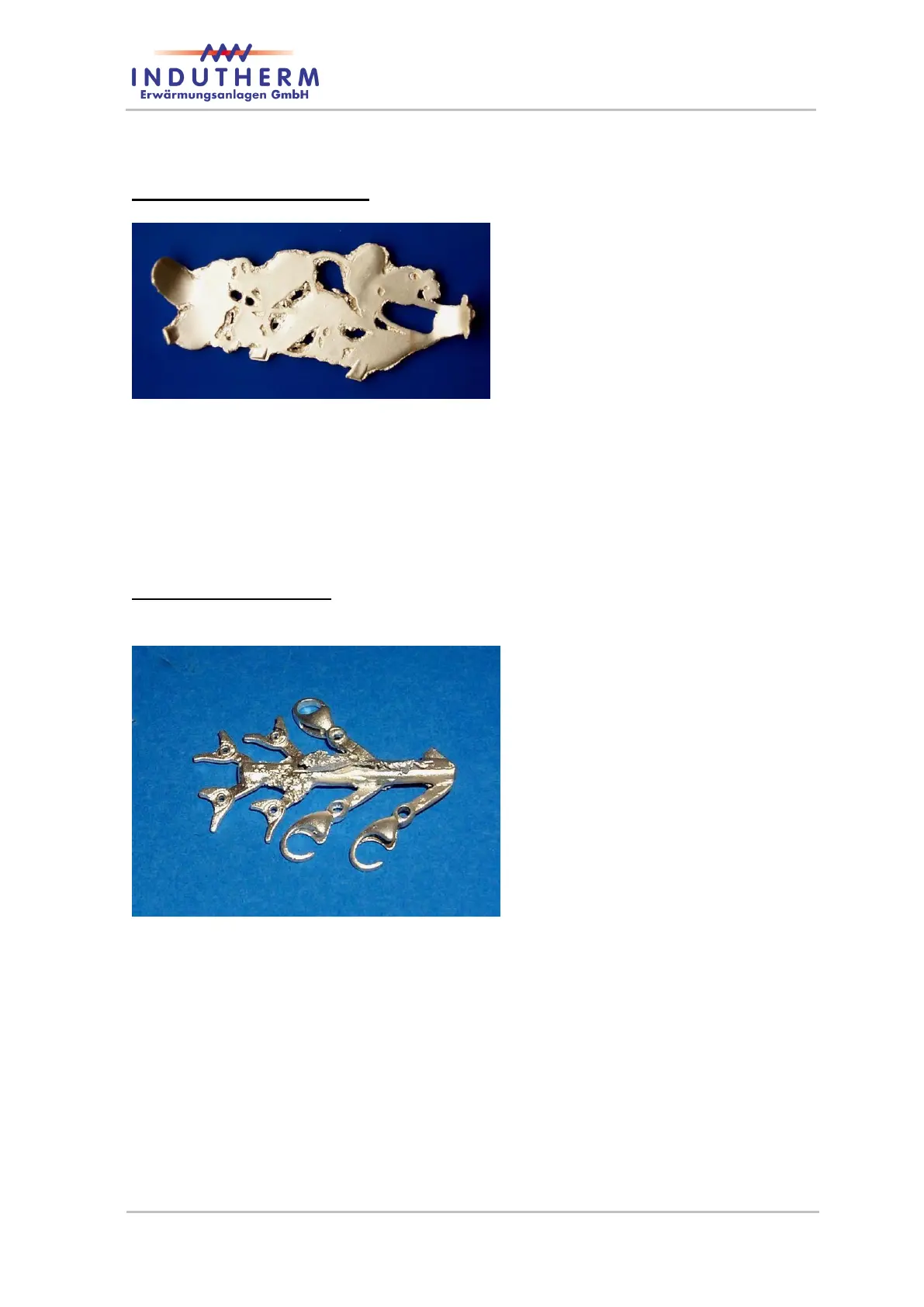

Other flashing or finning

Figure 19: other flashing or finning

Work cycle too long. Investment begin-

ning to set while still under vacuum.

Ensuring the work cycle is not too long

and slurry temperature is 20 – 22 ºC.

Disturbing the flasks too soon.

Leave the flasks for at least one hour

undisturbed.

Heating too quickly during de-wax.

Do not put the flasks in the hot oven. Do

not exceed 150 ºC during de-waxing.

Moulds allowed drying out before burn-

ing out.

If not burning out the same day, keep

moulds wet by covering with wet sack-

ing or plastic sheets.

Loading...

Loading...