sales@romanoff.com | www.romanoff.com

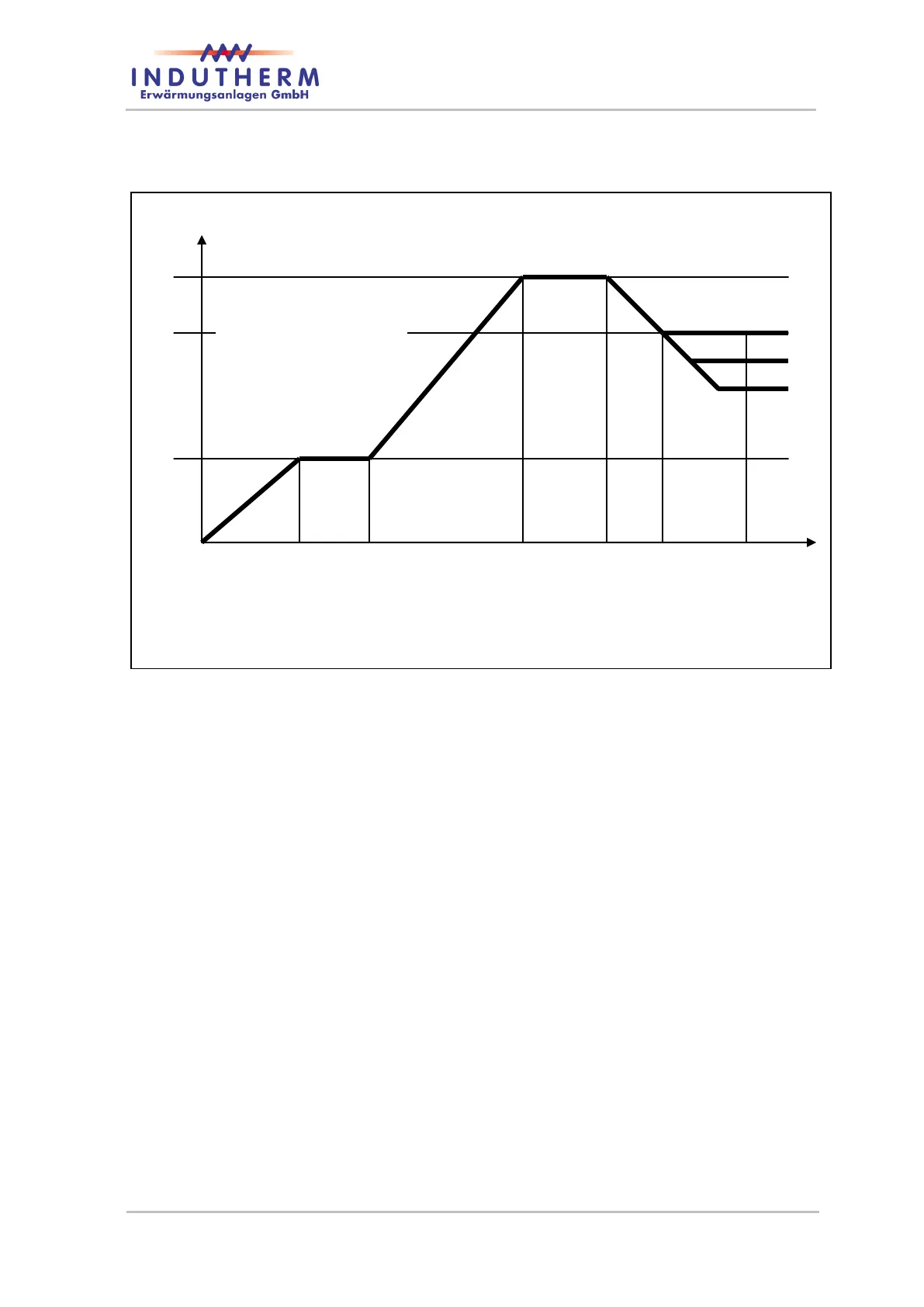

But it is also possible to push this cycle. Here a recommendation of a RAPID firing cycle:

Figure 17: Rapid firing cycle

Caution: In case of a “gentle”-firing cycle all amenities of the investment material are pre-

vented from damage. A rapid firing cycle doesn’t take care on these amenities. Already

aged investment powder or thus of lower quality can react because of gruff handling with

cracks.

In the dental field, most people are using “SPEED”-investment material. The fresh invest-

ed flask can be set into the HOT furnace directly. After 1-hour the flask is ready for cast-

ing. Please ask a Dental Depot about this investment material.

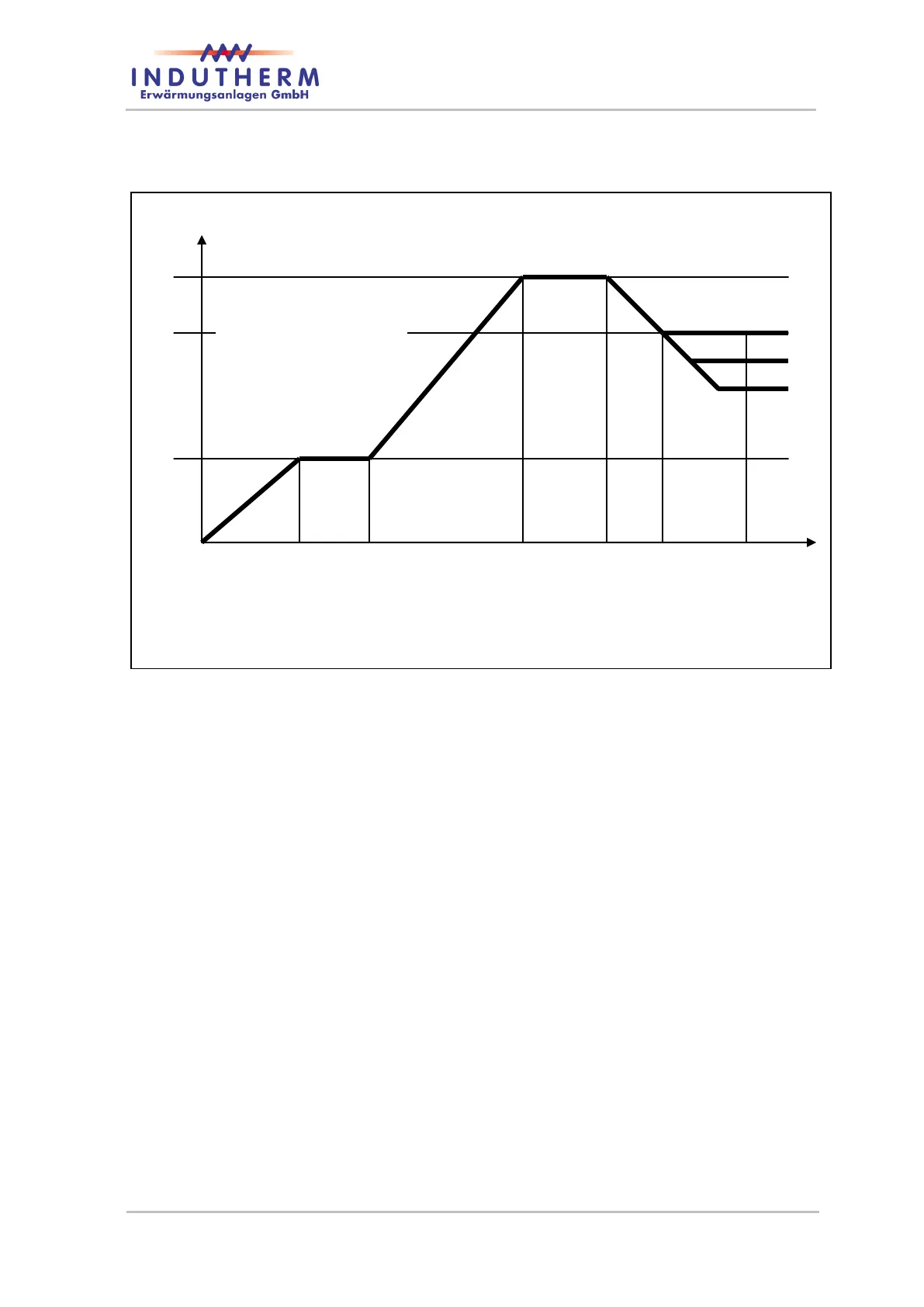

Standard-burnout-cycle for gypsum: (from investment to casting 6.5 hrs)

Resting time after investment 30 min,

in 2 hrs (2.5 °C/min) to 300 °C, holding time 30 min,

in 2 hrs (6 °C/min) to 730 °C, holding time 30 min (with flasks Ø 65 mm x 80 mm and Ø 80

mm x 80 mm should the holding time be extended to 60 min) and

in 30 min (4.3 °C/min) to 600 °C, holding time 30 min.

Rapid-cycle gypsum: (from investment to casting 3 hrs)

Resting time after investment 30 min,

in 30 min (10 °C/min) 300 °C, holding time 30 min,

in 30 min (14.3 °C/min) auf 730 °C, holding time 30 min (with flasks Ø 65mm x 80 mm and

Ø 80 mm x 80 mm should the holding time be extended to 45 min) and

in 10 min (13 °C/min) to 600 °C, holding time 20 min.

RAPID firing cycle for flasks MC60V gypsum bonded investment material

Loading...

Loading...