Terminals

‑92‑

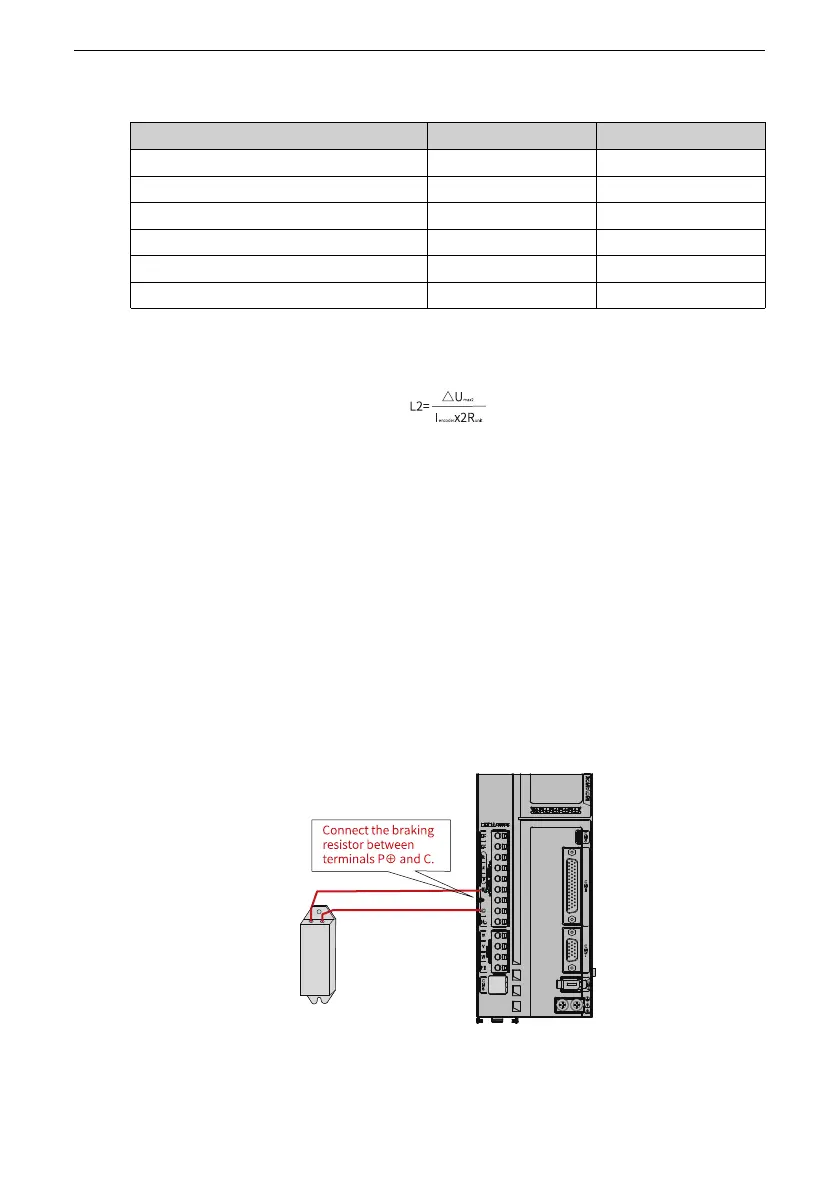

Table 4–24 Recommended cable between the servo drive and linear motor encoder

Cable Size

Ω/km

Allowable Length (m)

26 AWG (0.13 mm

2

)

143 8.0

25 AWG (0.15 mm

2

)

89.4 14.0

24 AWG (0.21 mm

2

)

79.6 15.0

23 AWG (0.26 mm

2

)

68.5 18.0

22 AWG (0.32 mm

2

)

54.3 23.0

21 AWG (0.41 mm

2

)

42.7 29.0

Suppose the current consumed by the motor encoder is higher than 200 mA,

you can select the cable based on the following formula.

Where, △U is 0.5 V, I

encoder

represents the current consumed by the encoder (see the

encoder user guide for details), and R

unit

represents the unit resistance (Ω/km) of the

cable.

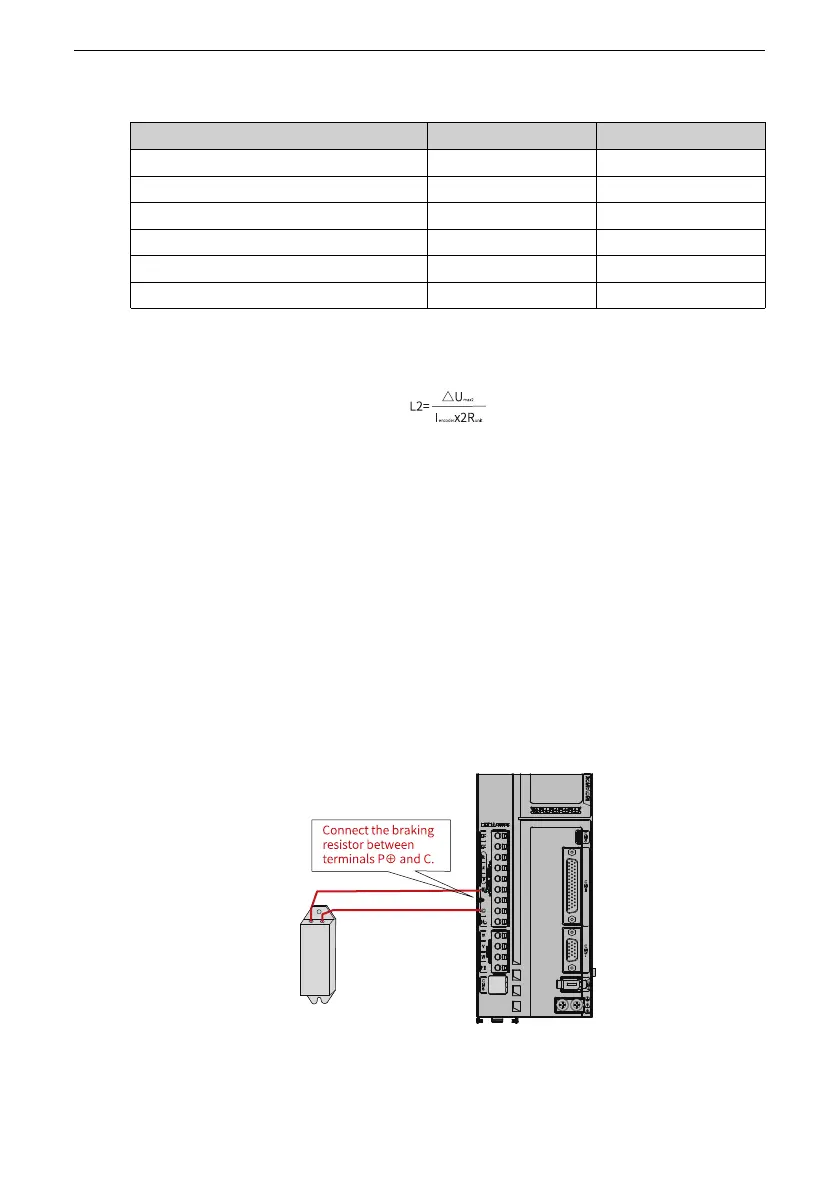

4.8 Wiring of the External Regenerative Resistor

Connecting the regenerative resistor

When the motor torque direction is opposite to the direction of rotation, the energy is

fed back to the servo drive from the motor side, leading to bus voltage rise. Once the

bus voltage rises to the braking threshold, the excessive energy must be consumed by

a regenerative resistor. Otherwise, the servo drive will be damaged. The regenerative

resistor can be a built‑in or an external one. However, a built‑in regenerative resistor

cannot be used together with an external one.

Figure 4‑24 Wiring of external regenerative resistor

Loading...

Loading...