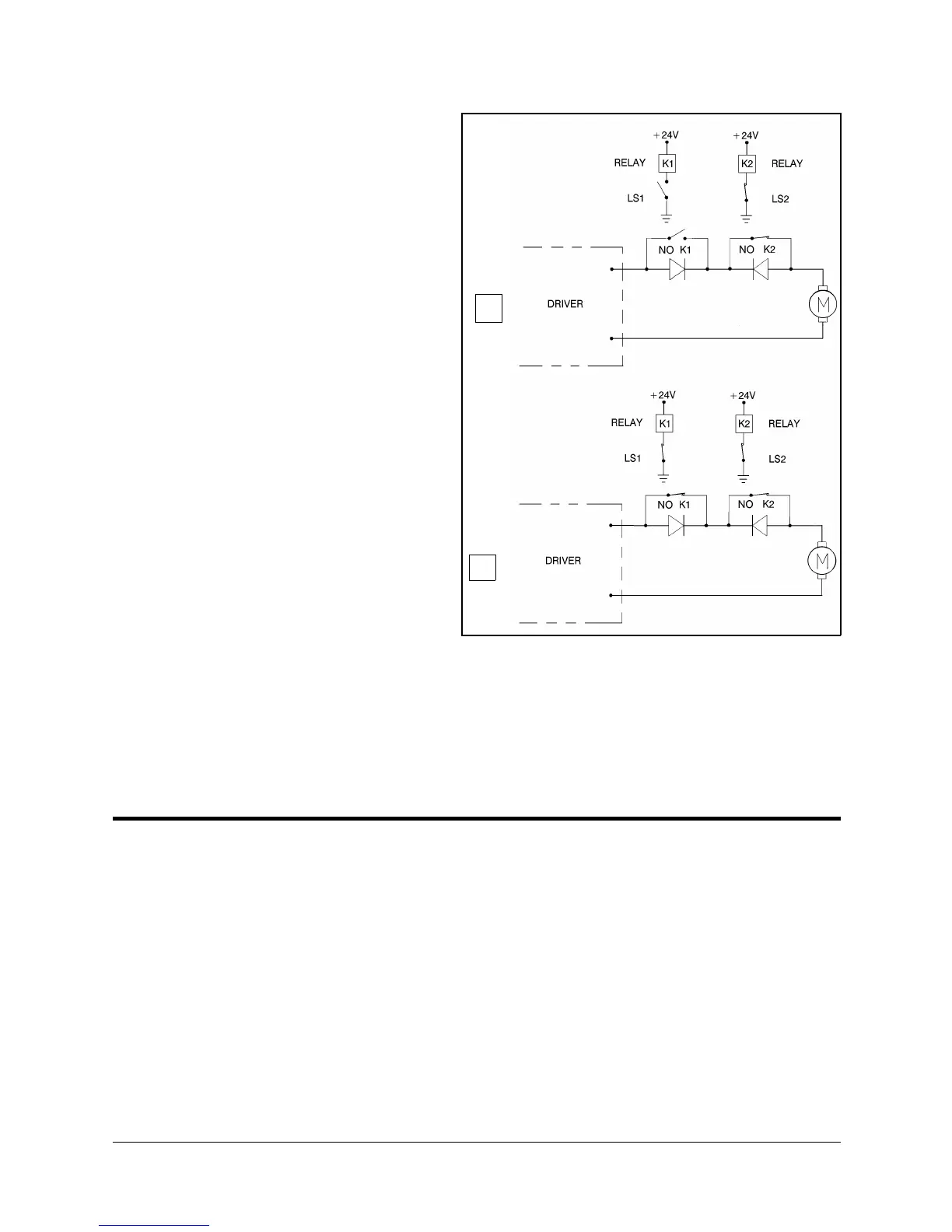

As shown in Figure 7-7A,

when limit switch 1 is

activated (that is, when the

button is depressed), the relay

contact opens and the relay is

deenergized. The motor

cannot move the joint beyond

this point. The diode allows

the motor to reverse

direction, thus permitting the

joint to move away from the

limit switch.

When the limit switch is

activated, it causes a control

error, resulting in the

activation of COFF (control

off mode), and an impact

protection message.

CON (control on mode) must

be activated and the robot

arm must be manually moved

(using keyboard or teach

pendant) away from the

impact condition.

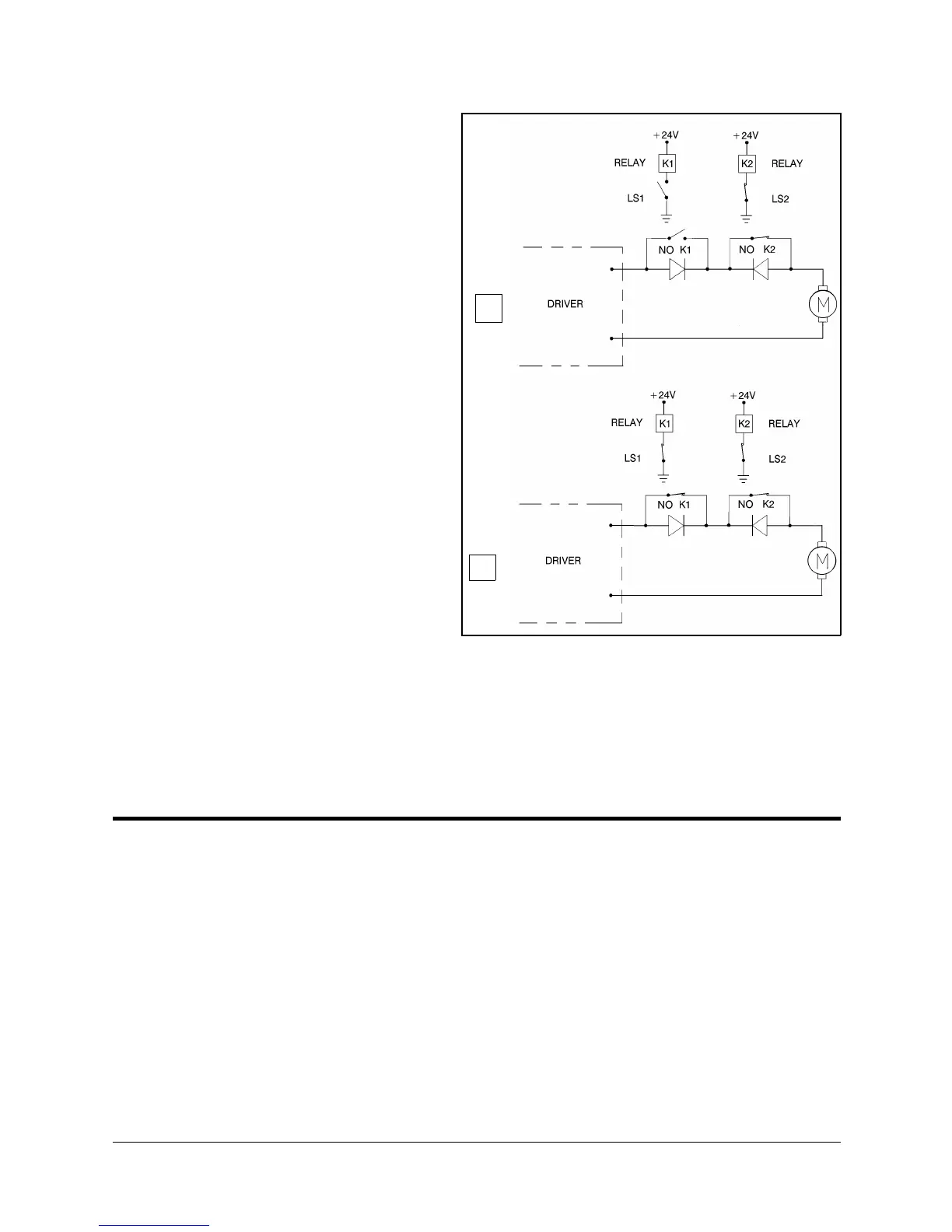

As long as the axis has not reached one of its limits, the relay contact remains

closed, and the diode has no effect on the circuit, as shown in Figure 7-7B.

Current can flow in either direction; the motor is thus able to rotate in either

direction.

Hard Stops

When the software limits and/or the end of travel switches fail to halt the

movement of the robot arm, it is possible that the momentum of the robot arm

will drive it until it reaches its mechanical limit.

When the joint reaches this hard stop, the impact protection and thermic

protection processes detect an error, thus activating COFF.

CON must be activated and the robot arm must be manually moved away from

the impact condition.

A

B

Figure 7-7: Axis Limit Circuit

User’s Manual 7 - 5 SCORBOT-ER IX

9603

Loading...

Loading...