Page 26

4.10.2 Installation of a Complete New Concentric

Stainless Steel Venting System.

For a vertical venting system, locate the boiler to aect

the shortest possible vent length run with the

maximum venting length not to exceed 25 feet and no

more than 3 90° elbows.

Venting Assembly Process:

Note:

Follow the detailed instructions supplied with

the Heat-Fab SC series venting components during

the assembly process.

1)

Install the Dual pipe to concentric adaptor, kit

FT3006. Ensure that the ttings are clean, moisten the

seals and pipe ends before insertion and insert the

Dual pipe to concentric adaptor, kit FT3006 into the FT

boiler sockets until they bottom out. Tighten the

clamps on the boiler vent connectors.

2)

The venting system will probably have both

horizontal and vertical components to align the Dual

pipe to concentric adaptor, kit FT3006, and the

penetration through the roof.

3)

The selection on the roof for the roof termination

must follow the guidelines of Section 4.9 Vent / Air

Termination, Page 22 in this manual.

4)

Locate the FT boiler as close as possible to the site

of the roof termination overhead and determine the

routing of the venting system and measure the

required lengths of horizontal and vertical runs.

5)

Properly support each horizontal and vertical

section at least every 4 ft and at each elbow. Finish

the vertical section by the installation of the SCO3VT

Vertical Terminal Adapter on the last piece of vertical

concentric vent pipe.. The top of this adapter must be

12” above the roof or anticipated snow line where it

penetrates the roof. Install a SCO3RC, Rain Cap.

6)

After completion of the venting system, review all

joints of the venting installation and make sure that all

locking screws of the adjoining vent sections are all

fully installed into the pre-drilled holes.

For a horizontal venting system do not exceed the

maximum allowed lengths and number of elbows

noted above and select a location for the vent

termination on the outside wall. This location must

consider the 12” height above grade and/or anticipated

snow line and its proximity to windows, doors and

sources of incoming air, etc. Reference Section 4.6

Locations for Vent Pipe Terminator, Page 18 in this

manual.

Venting Assembly Process:

Note:

Follow the detailed instructions supplied with

the Heat-Fab SC series venting components during

the assembly process.

1)

Locate the FT boiler as close as possible to the

selected location for the penetration through the

outside wall and install the Dual pipe to concentric

adaptor, FT3006 kit, in the sockets on the FT boiler.

Ensure that the ttings are clean, moisten the seals

and pipe ends before insertion and insert the Dual

pipe to concentric adaptor, FT3006 kit, into the FT

boiler sockets until they bottom out.

2)

Determine the routing of the venting system and

measure the required lengths of horizontal and vertical

runs. Keep in mind that telescoping pieces may be

required for certain lengths as the pipes can NOT be

trimmed to length. Each vertical and horizontal run

must be supported by hangers every 4 ft so that it

slopes 3/8” per foot downward toward the FT boiler

and has no low sections that will limit the ow of

condensate back to the boiler.

3)

The telescoping sections are used to adjust both

the vertical and the horizontal sections of the pipes so

that the proper slope can be maintained.

4)

Install the 3" x 5" horizontal termination adaptor

(SCO3HT) on the last piece of horizontal concentric

vent pipe protruding through the exterior wall and

select one of the listed horizontal terminations to

complete the concentric venting installation.

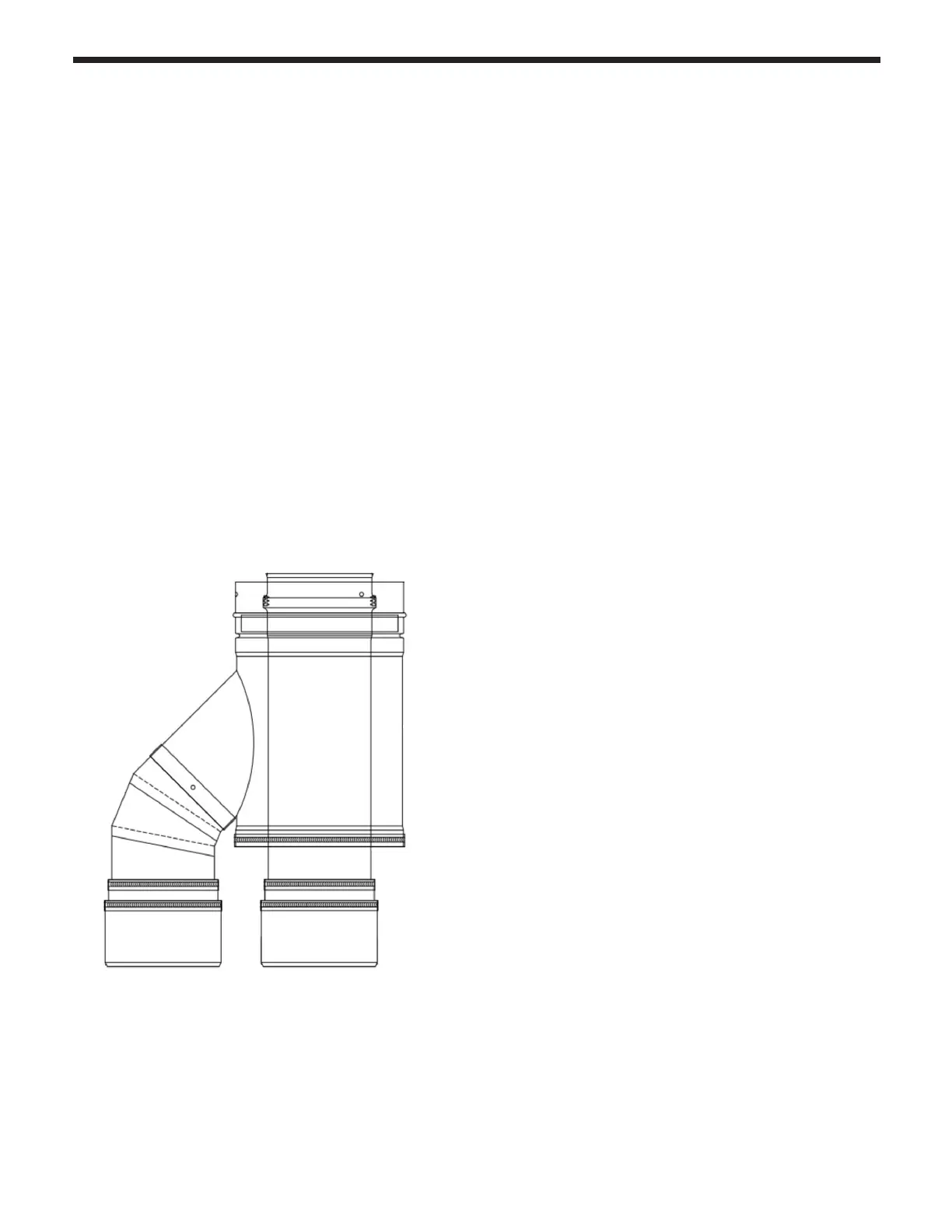

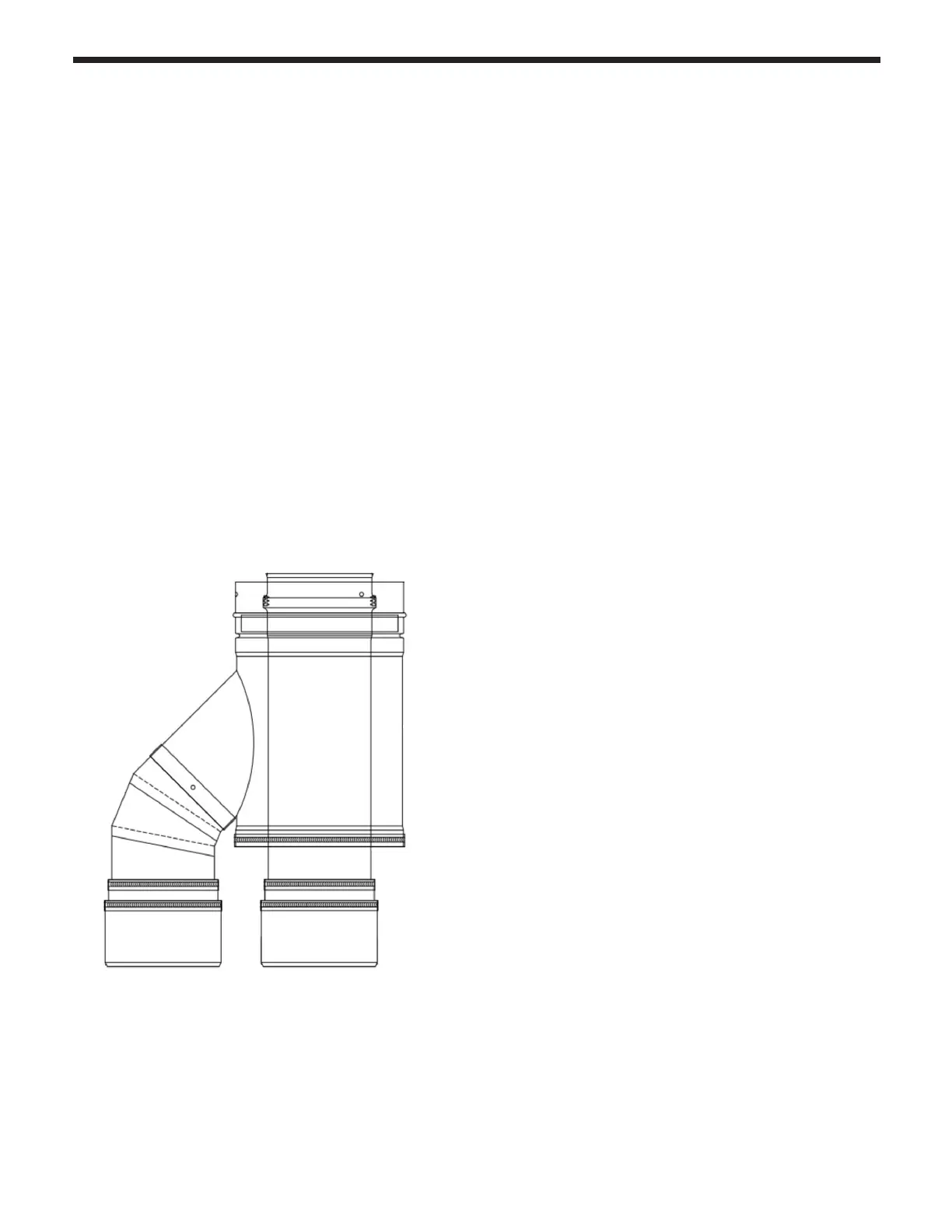

FT3006 Kit

Loading...

Loading...