Page 48

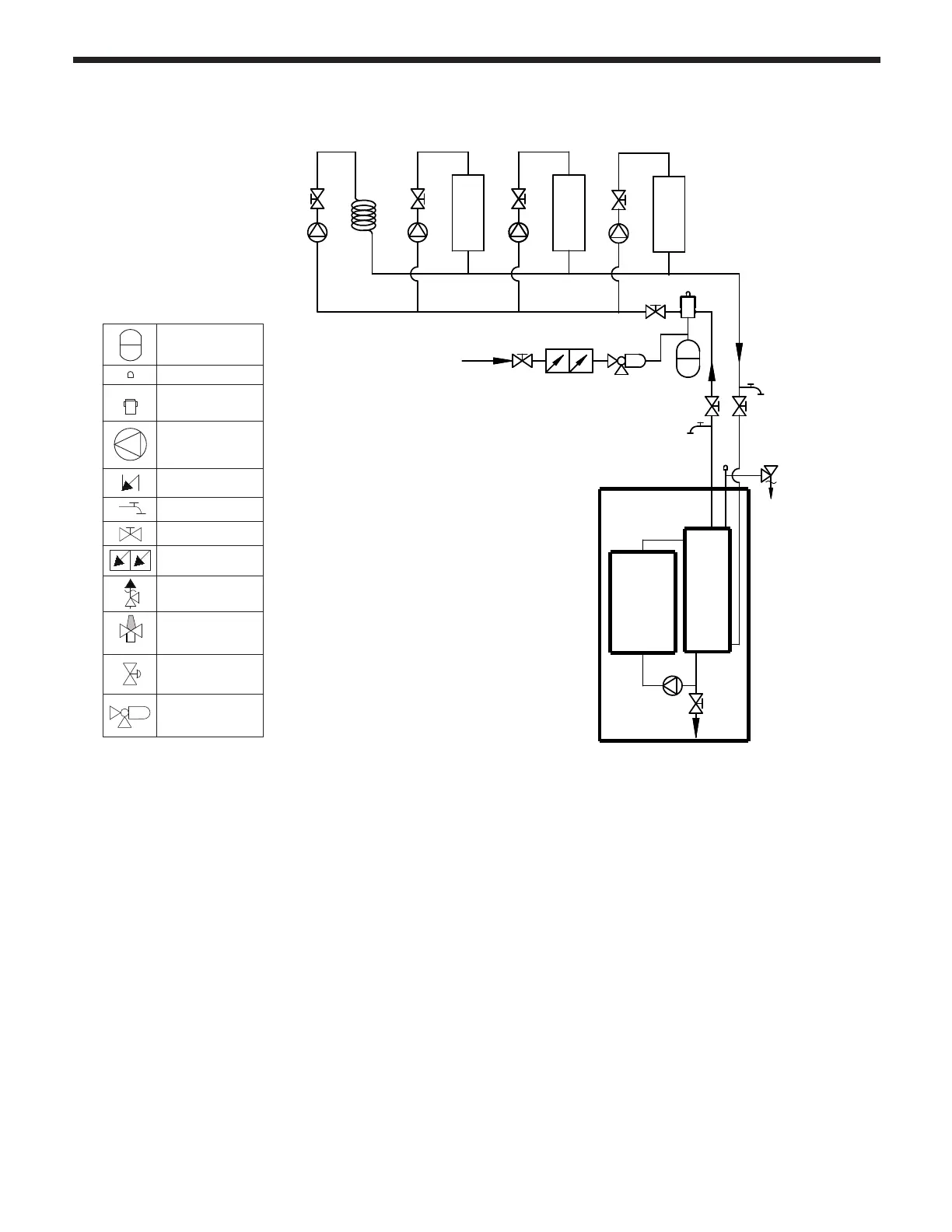

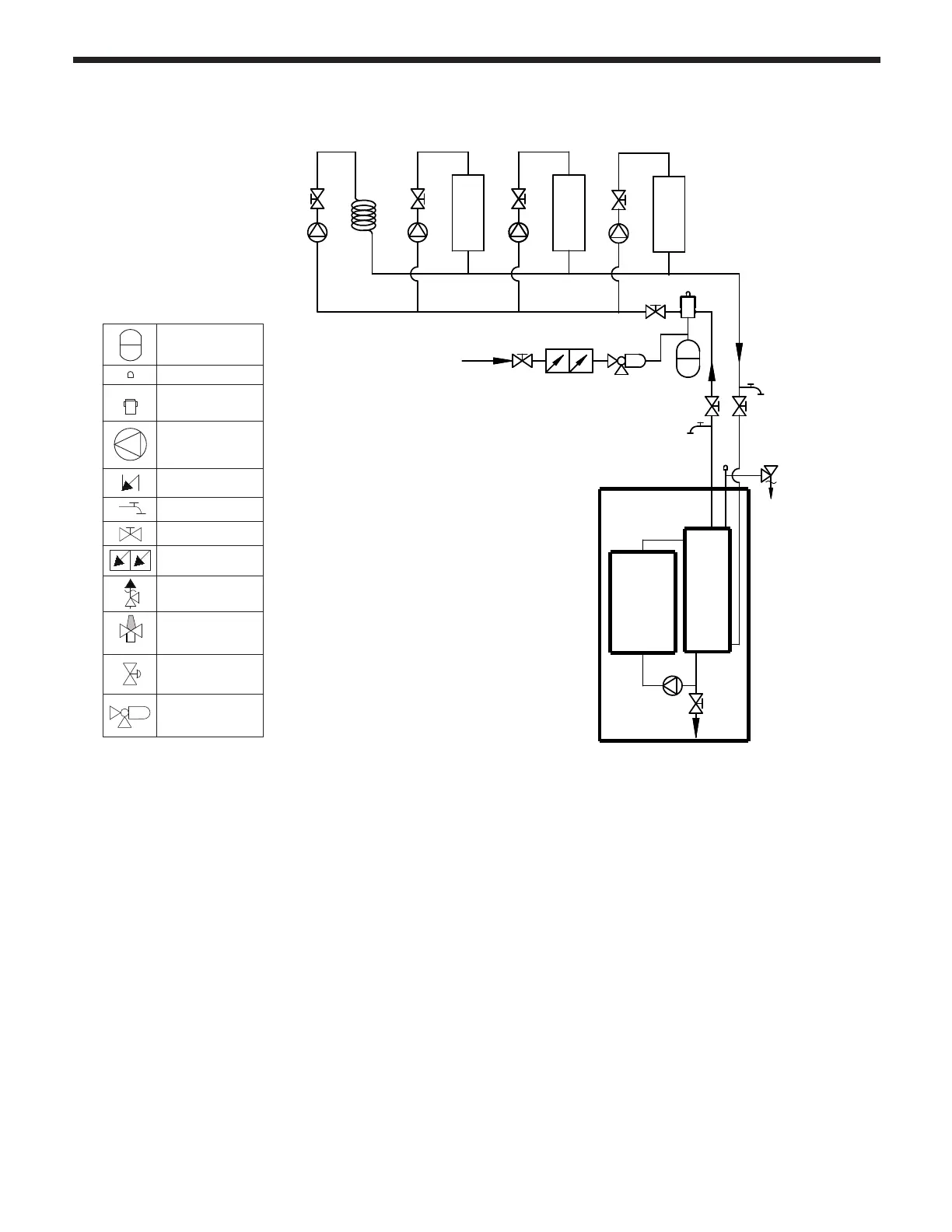

4.16.6 Zoning with pumps and indirect DHW tank pump.

1. This piping diagram is meant to show system piping concept only. Installer is responsible for all

equipment and detailing required by local codes.

2. The minimum size piping to the Indirect Tank heat exchanger is ¾” inside diameter.

3. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

4. The system return must be piped directly to the Boiler Return connection.

5. The system supply must be piped directly to the Boiler Supply connection.

6. The heat exchanger in the Indirect Tank shall be piped as a separate zone. Power the pump

for the indirect tank from the DHW tank terminals. The (dry contact) aquastat or DHW sensor

connects back to the DHW sensor terminals of the boiler.

7. Manufacturer strongly recommends the use of an anti-scald mixing valve at the hot water outlet

of the Indirect Tank to reduce the potential for scalding. Check with local codes.

(FACTORY

WIRED)

LLH

ZONE 2

MFTHF Multizone Heating w Circulators & Indirect Tank

ZONE 3

MAKE UP

WATER

ZONE 1

INDIRECT H-X

A

B

EXPANSION

TANK

BACKFLOW

PREVENTER

PURGE

VALVE

AIR

ELIMINATOR

CHECK

VALVE

ISOLATION

VALVE

REDUCING

PRESSURE

VALVE

AIR

VENT

CIRCULATOR

RELIEF

T & P

VALVE

E

B

O

I

L

R

Circulation pump

Check valve

Zone valve

Pressure

reducing valve

Drain valve

Gate valve

Backflow preventer

Pressure Relief Valve

Expansion tank

Air separator

(Diaphragm-type)

Automatic air vent

Anti-scald rated

Mixing Valve

Check Valve

Shut-off valve

Circulation pump

with built-in IFC

Loading...

Loading...