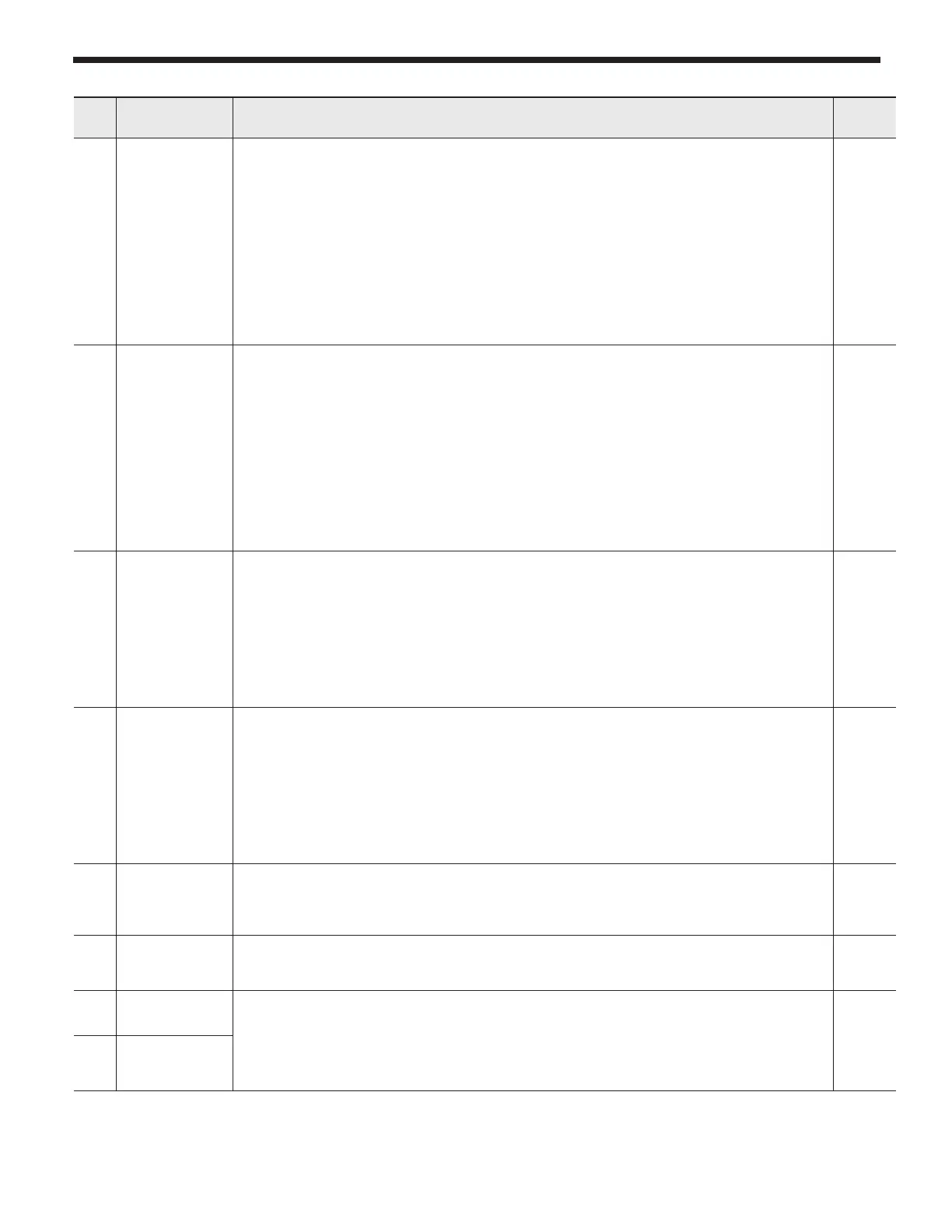

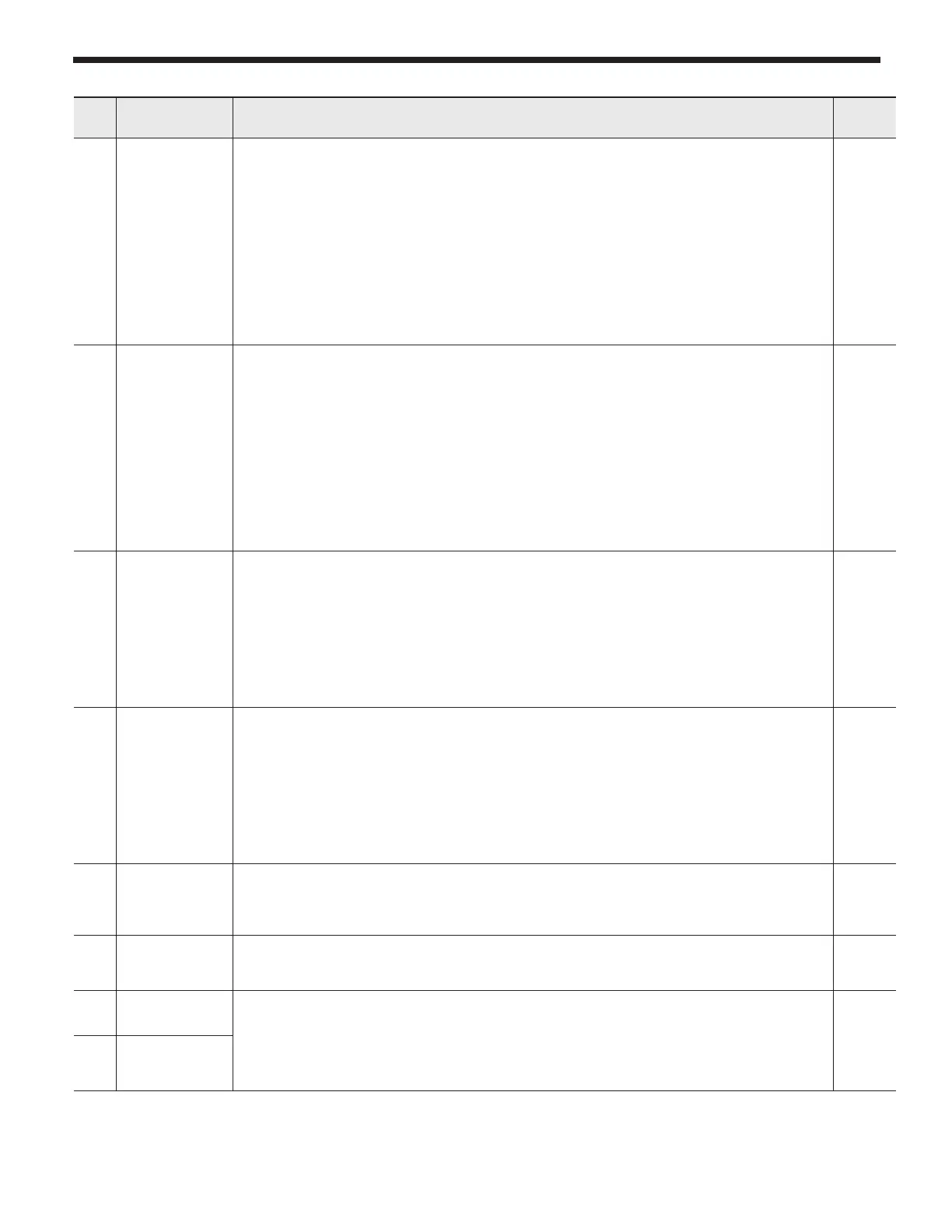

Page 70

SECTION 6 Error Codes

Error

Code

Error Code

Description

Possible Remedies

Recover

methods

10

Combustion

fault Flame has

Extinguished 8

(Eight) Times

Press the Power button to clear the Error Code. If Error happens again:

1. Monitor the gas pressure to the appliance while in operation. Ensure pressure is between 3.5” to 10.5” WC

(Nat. Gas) and 8” to 13” WC (Propane).

2. Check gas valve wire. Ensure connection is secure.

3. Check ame detection sensor. Ensure connections are secure. Normal operating settings are more than

2.5DC before ignition, less than 2.5DC after ignition.

4. Check exhaust and intake terminations for blockages. Also verify that intake, intake boot, blower and burner

housing is free of blockages and debris.

5. Assure that the ame is stable when lit. Conrm Flame stability by manually forcing the boiler into Low Fire

(see section 4.20) - Burner should not cycle on and off in low re. If burner cycles on/off during low re

operation adjust fuel/air mixture and conrm CO

2

values are within range for model and fuel type.

6. If the problem persists, contact technical support.

Hard

Lock

11

Ignition fault

Ignition has Failed

10 (Ten) Times

Press the Power button to clear the Error Code. If Error happens again:

1. Monitor the gas pressure to the appliance while in operation. Ensure pressure is between 3.5” to 10.5” WC

(Nat. Gas) and 8” to 13” WC (Propane).

2. Check gas valve wire. Ensure connection is secure.

3. Check ame detection sensor. Ensure connections are secure. Normal operating settings are more than

2.5DC before ignition, less than 2.5DC after ignition.

4. Check igniter transformer for proper connection.

5. Clean the spark igniter with steel wool to remove oxides. Ensure proper separation (3-4 mm).

6. Replace the spark igniter if damaged. Remove and inspect burner. If burner is damaged/blocked - replace

burner

7. Assure that the ame is stable when lit.

8. If the problem persists, contact technical support.

Hard

Lock

16

Water temperature

over-heating fault

Operating

Temperature

Sensor detects

Water Temperature

Greater than 203°F

(95°C)

Press the Power button to clear the Error Code.

If boiler is not piped Primary/Secondary it is likely the internal boiler pump is not able to move enough water thru

heat exchanger. If Error happens again:

1. Check if dip switch Max Fire setting is ON. Switches 6 and 7 should be OFF for normal operation.

2. Check if CH inlet pipe is blocked. Ensure there is enough water owing to the appliance.

3. Check Operating Temperature sensor at CH heat exchanger outlet. If resistance is zero, replace the sensor.

4. Verify operation of internal boiler pump by checking rotation of pump shaft. (Manually spin pump shaft by

inserting a at head screwdriver. You may need to remove a side panel knock-out for better access).

5. If the problem persists, contact technical support.

Hard

Lock

20

Blocked

condensate switch

fault

Press the Power button to clear the Error Code.

1. Check Condensate and main controller connections. Ensure all are secure.

2. Check Condensate sensor resistance. If resistance is zero, replace the switch.

3. Check Condensate hose. Ensure it is connected and in good condition.

4. Check condensate line and termination for blockages.

5. Check Vent Pipe for blockages.

6. If the condensate is “hard piped” in the eld, install a vent in the piping at a point higher than the

condensate trap.

7. If the problem persists, contact technical support.

Hard

Lock

28

Overheat

sensor fault

This Error Code will go away when CH temperature decreases. If Error happens again:

1. Check overheat temperature sensor. Ensure connections are secure.

2. Check overheat sensor resistance. If resistance is zero, replace the sensor.

3. If the problem persists, contact technical support.

Soft Lock

29

Factory installed

Jumper missing

or not connected.

1. Check upper left plug on PCB board. Reconnect blue jumper wire part of this plug.

2. Press the Power button to clear the Error code. Error occurs when the blue wire inside the KI-I9CCWL plug

(upper left corner of PCB board) is shorted to ground or has a poor contact.

Hard

Lock

32

DHW outlet

sensor fault

This Error Code will go away when CH temperature decreases. If Error happens again:

1. Check DHW or CH temperature sensor. Ensure connections are secure.

2. Check DHW or CH sensor resistance. If resistance is zero, replace the sensor.

3. If the problem persists, contact technical support.

Soft Lock

33

OP Water

temperature

sensor fault

6.1 Error Code Tables

Loading...

Loading...