The FT Series Floor Standing, Heating Only Boiler

Page 71

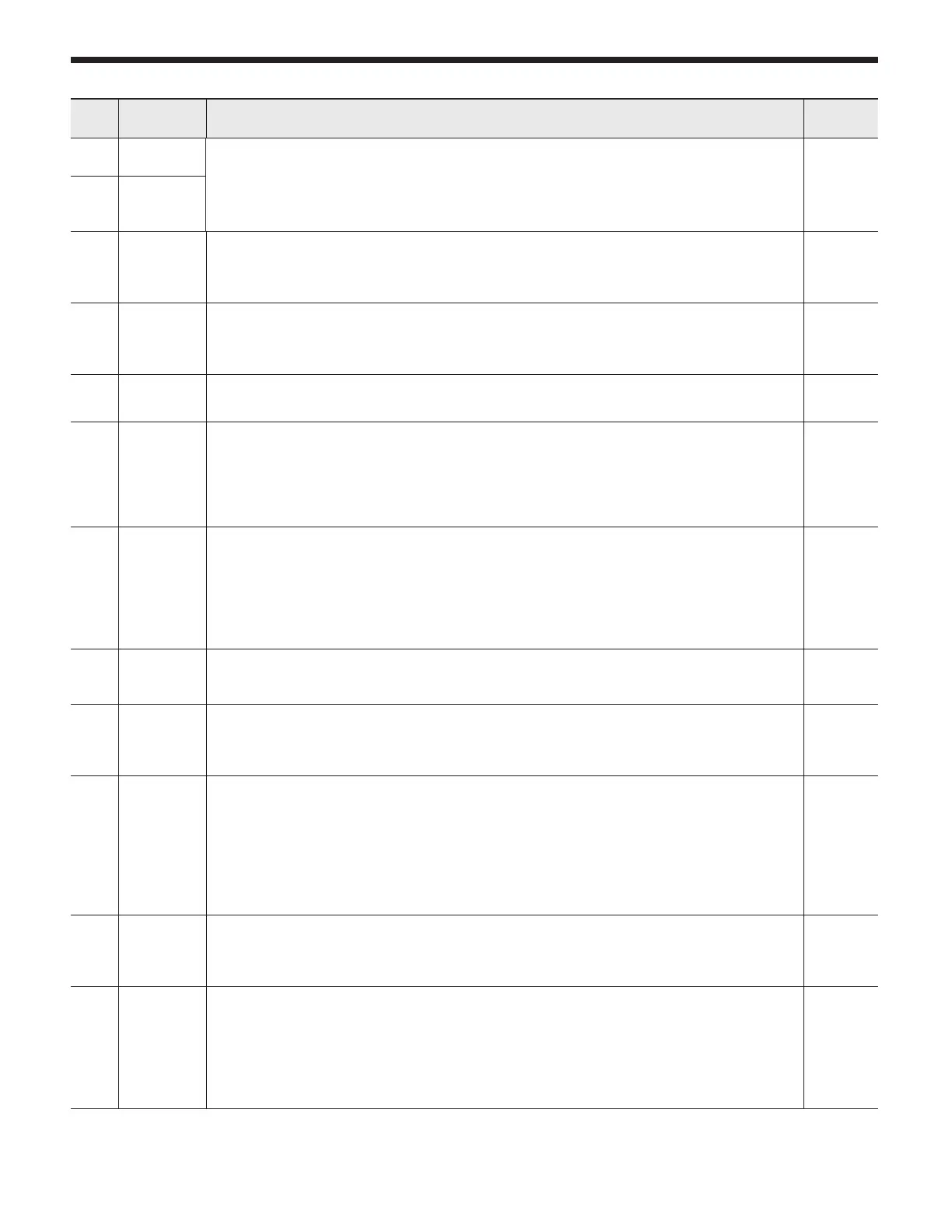

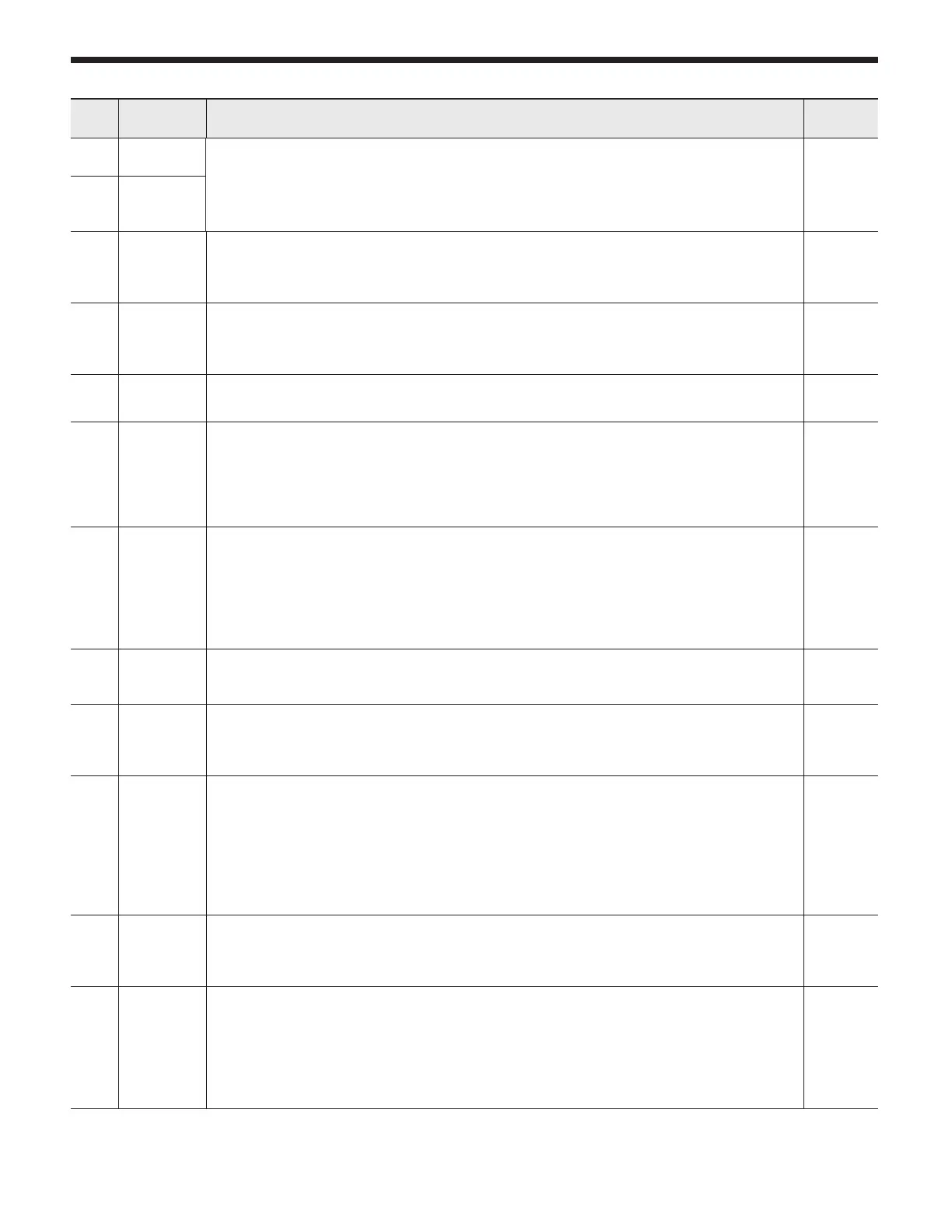

Error

Code

Error Code

Description

Possible Remedies

Recover

methods

32

DHW outlet

sensor fault

This Error Code will go away when CH temperature decreases. If Error happens again:

1. Check DHW or CH temperature sensor. Ensure connections are secure.

2. Check DHW or CH sensor resistance. If resistance is zero, replace the sensor.

3. If the problem persists, contact technical support.

Soft Lock

33

OP Water

temperature

sensor fault

36

Main power

fault

Supply voltage is too low to operate. This Error Code will go away when supply voltage returns to normal

operating range. If Error happens again:

1. Ensure appliance is properly wired to a power source meeting the requirements on the rating plate.

2. If problem persists,

contact technical support.

Soft Lock

37

Power

frequency

fault

Supply frequency is too high to operate. This Error Code will go away when supply frequency returns to normal

operating range. If Error happens again:

1. Ensure appliance is properly wired to a power source meeting the requirements on the rating plate.

2. If problem persists,

contact technical support.

Soft Lock

38 EPROM fault

Press the Power button to clear the Error Code.

If the problem persists. contact technical support.

Hard Lock

40

Gas leakage

fault

IMPORTANT: If you smell gas, STOP! Follow the instructions on page 2, this manual, and call a qualied

service technician or the fuel gas utility. Press the Power button to clear the Error Code. If Error happens again:

1. Check the appliance cover. Ensure it is secure.

2. Check gas connections for leakage with a soapy solution. Fix any leaks.

3. Check condition of the burner assembly.

4. If the problem persists,

contact technical support.

Hard Lock

41

Fan high

RPM fault

Press the Power button to clear the Error Code. If Error happens again:

1. Check the vent connections for blockages.

2. Check the burner assembly.

3. Check fan operation. If fan appears to be operating normally but RPMs are too high, replace the fan.

4. Check intake and exhaust for blockages, debris, proper installation and placement. Check and record SFN

(revision # of printed circuit board during start-up for future reference).

5. If the problem persists,

contact technical support.

Hard Lock

42

External

LWCO/

safety fault

Press the Power button to clear the Error Code. If Error happens again:

1. Ensure the LWCO jumper wire is properly connected.

2. If the problem persists,

contact technical support.

Soft Lock

43

Burner over-

heating fault

Press the Power button to clear the Error Code. If Error happens again:

1. Check burner overheat switch connections. Ensure connections are secure.

2. Check switch resistance. If resistance is zero, replace the switch.

3. If the problem persists,

contact technical support.

Hard Lock

44

Air

Pressure

Sensor

Range (APS)

Fault

Press the power button to reset If error happens again:

1. Check the vent pipe for blockages.

2. Check the air intake pipe for blockages.

3. Inspect air intake lter screen located at the air intake adapter on top of the boiler. Clean if necessary.

4. Inspect the Venturi and fan motor, the air intake screen at the fan connection or the burner itself for any

debris that could have been drawn in by the fan through the air intake.

5. If error does not clear, replace the APS.

6. If the problem persists,

contact technical support.

Hard Lock

45

Air Pressure

Sensor Fault

Check the aps connection.

1. If APS is closed and connections are secure, check APS connection.

2. If the problem is not happen, replace the APS

3. If the problem persists,

contact technical support.

Soft Lock

61 Fan fault

This Error Code will go away when the condition is remedied. If Error happens again:

1. Check the connections to the fan. Ensure all are secure.

2. Check intake and exhaust for blockages and debris.

3. If the fan does not rotate during the ignition sequence, check for AC8V~26.5V power at the fan connection.

IfAC8V~26.5V power is present at the control, replace the fan. If the blower does not have AC8V~26.5V power,

check power at the control. If AC8V~26.5V power is not present at the control, replace the control.

4. If the problem persists,

contact technical support.

Soft Lock

SECTION 6. Error Codes (continued)

Loading...

Loading...