The FT Series Floor Standing, Heating Only Boiler

Page 51

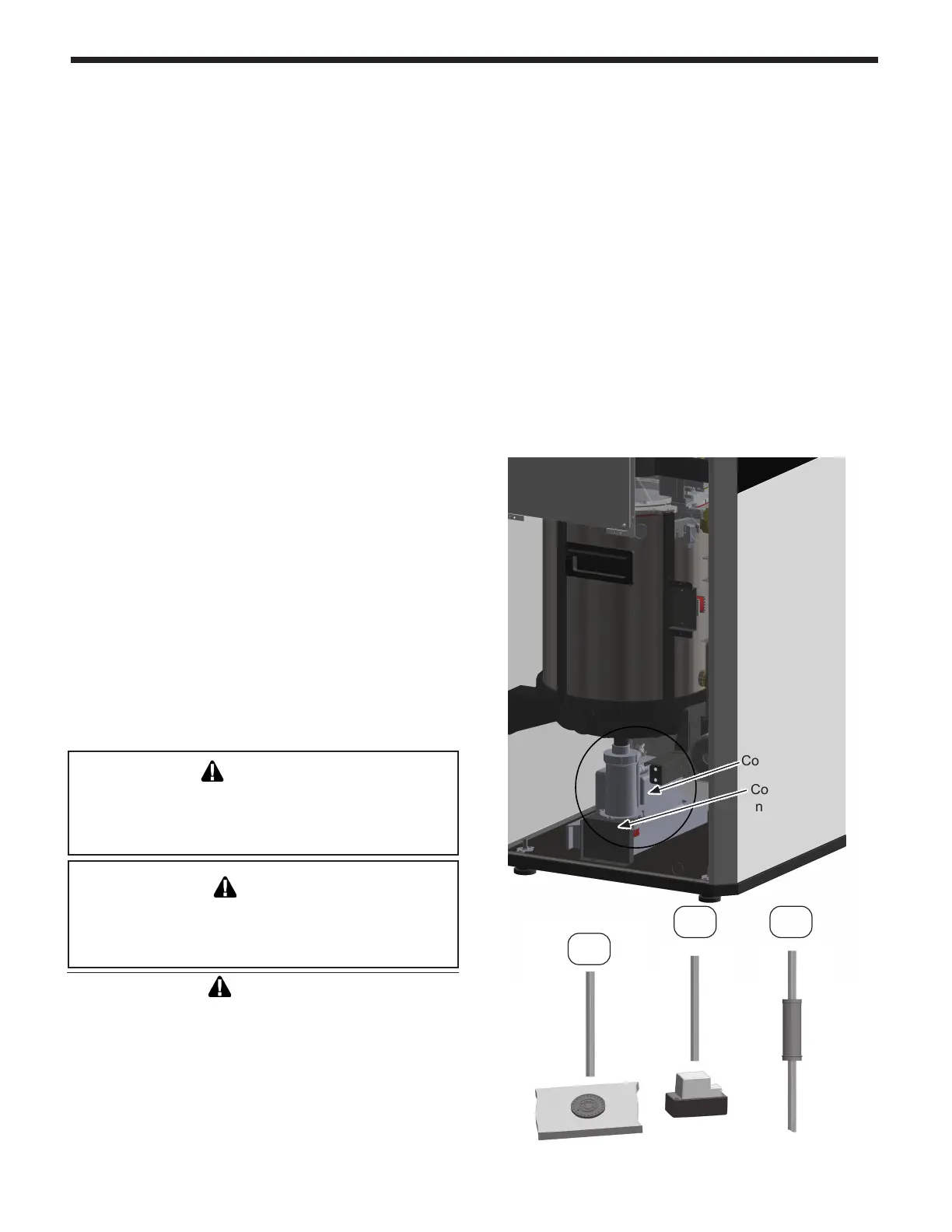

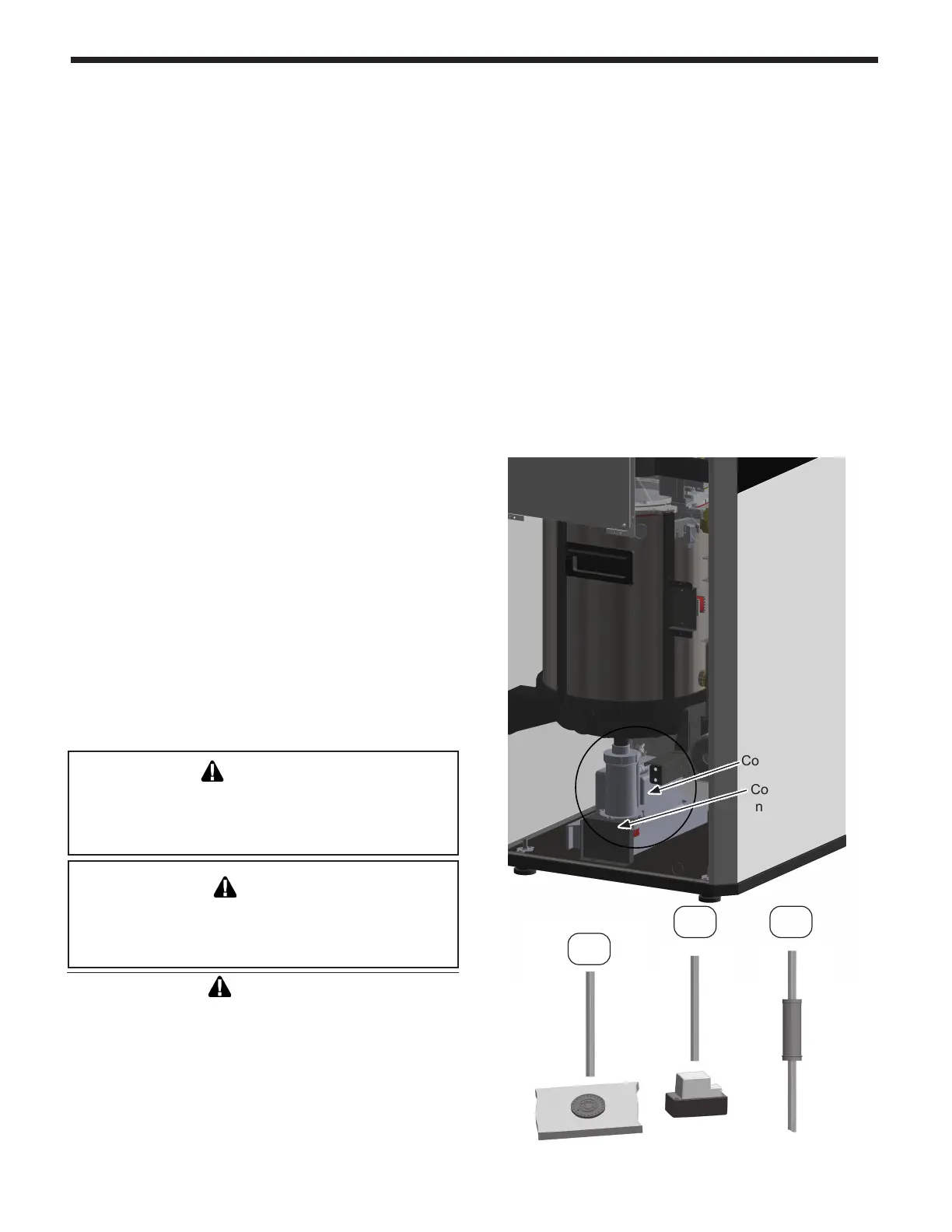

1

2 3

(View is as

if side panel

were removed)

Condensate Trap

Combination

neutralizer/

condensate

pump kit

• High eciency gas condensing boilers create

condensation when operating. Condensation is acidic

with a pH ranging from 4 to 5.

• Attach the supplied condensate drain hose to the

installed condensate trap. Make sure to attach

the 1/8” air vent tube and secure this 6” long hose

to a bracket so it will not spill condensate. Follow

your local code with regards to the disposal of

condensation.

One of 3 disposal methods must be followed

1. to a oor drain

2. Combination neutralizer and condensate pump

kit (optional kit available from manufacturer)

3. to a condensate pump (eld supplied)

• If a neutralizer is installed, periodic replacement of the

lime stone (or neutralizing agent) will be required. The

rate of depletion of the lime stone varies upon usage

of the boiler. During the rst year of operation, please

check the neutralizer every few months for depletion.

• Apply only corrosion-resistant materials for the

condensate drain lines such as 1/2˝ PVC, CPVC,

Polypropylene pipe or included plastic hose.

• In case of a closet installation, a combination

neutralizer/pump (FT3007 kit) can be installed by

removing the lower left access panel, an electrical

outlet (Max amp rating: 2 Amp) is provided to power

the condensate pump.

• Overall dimensions can not exceed 15-7/8” (L) x

5-7/16” (W) x 6-3/4” (H) in order to t inside the

boiler cabinet.

NOTICE

Category II & IV boilers must be installed with a means

provided for the drainage of condensate.

AVIS

les chaudières de catégories II et IV doivent être

installées avec un moyen de drainage du condensat.

CAUTION

Condensate is mildly acidic (pH=5), and may harm

some oor drains and/or pipes, particularly those

that are metal. Ensure that the drain, drainpipe, and

anything that will come in contact with the condensate

can withstand the acidity, or neutralize the condensate

before disposal. Damage caused by failure to install

a neutralizer kit or to adequately treat condensate

will not be the manufacturer’s responsibility.

Various condensate disposal methods

• If desired, a discharge 1/4” or 3/8” can be routed by

removing yellow cap from the top right rear corner

and routing the hose down to the condensate pump.

• Knock-out provisions are supplied in the lower left,

rear or right hand side panels to rout the condensate

to a nearby oor drain or externally placed

condensate pump.

• Cut a small opening in the plastic grommet and pull

the discharge hose through the opening for strain

relief.

• When placing the FT3007 kit or other suitable

condensate pump/ neutralizer combination inside

the cabinet, it may be necessary with a small clip

(not provided) to secure the condensate hose

coming from the trap to this cover. One can also use

the soft plastic insert, shorten the condensate drain

hose and carefully “thread” the hose into this insert

and place it into its designation location of the

FT3007 kit.

4.18 Disposal of Condensate

Loading...

Loading...