The FT Series Floor Standing, Heating Only Boiler

Page 41

800.900.9276 • Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355 (Applications Engineering)

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com

Document 4388

The FT Series, Wall Combi, Gas Conversion Kit

pg 3 of 4

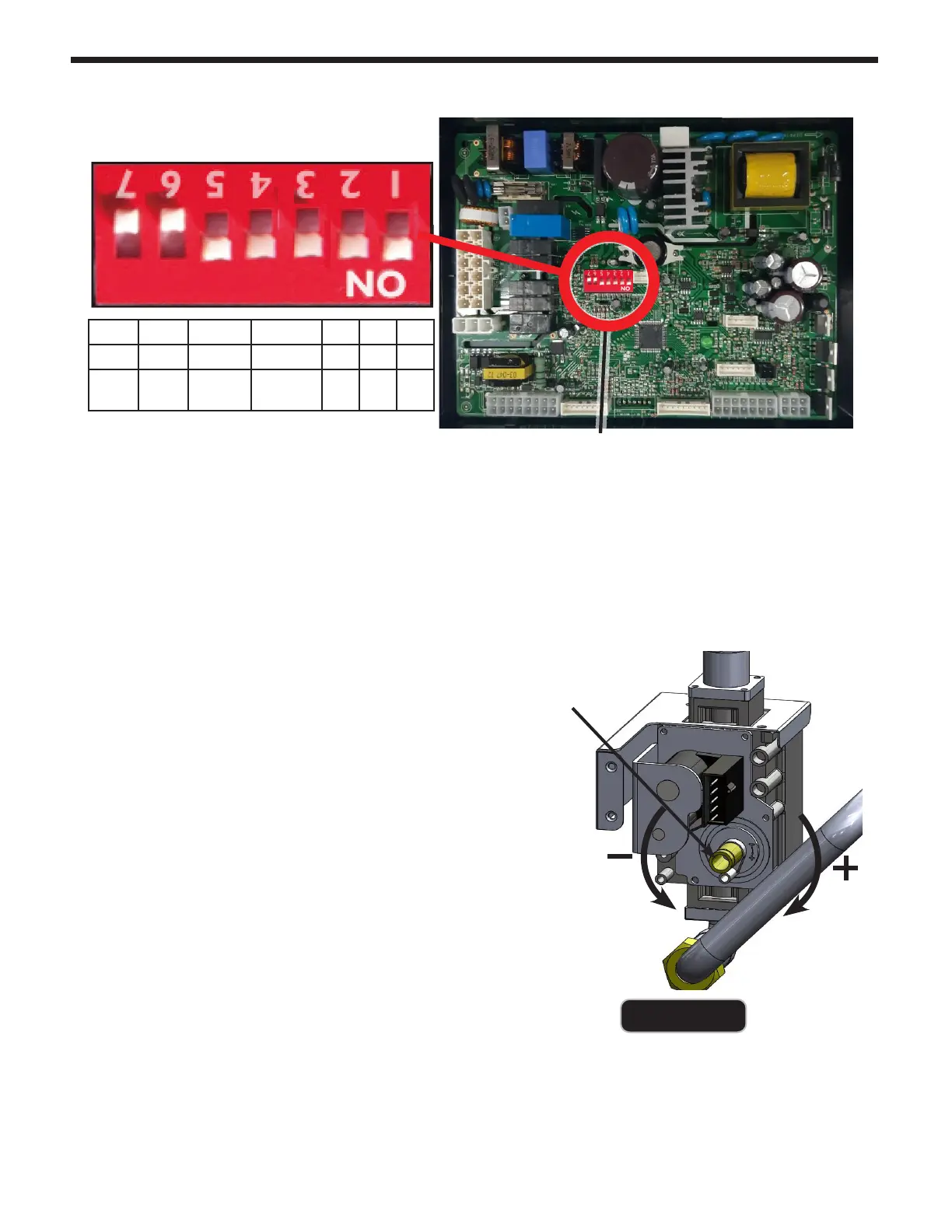

Gas Valve

Adjustment Port

+

+

-

-

Gas Valve

Adjustment Port

Figure D

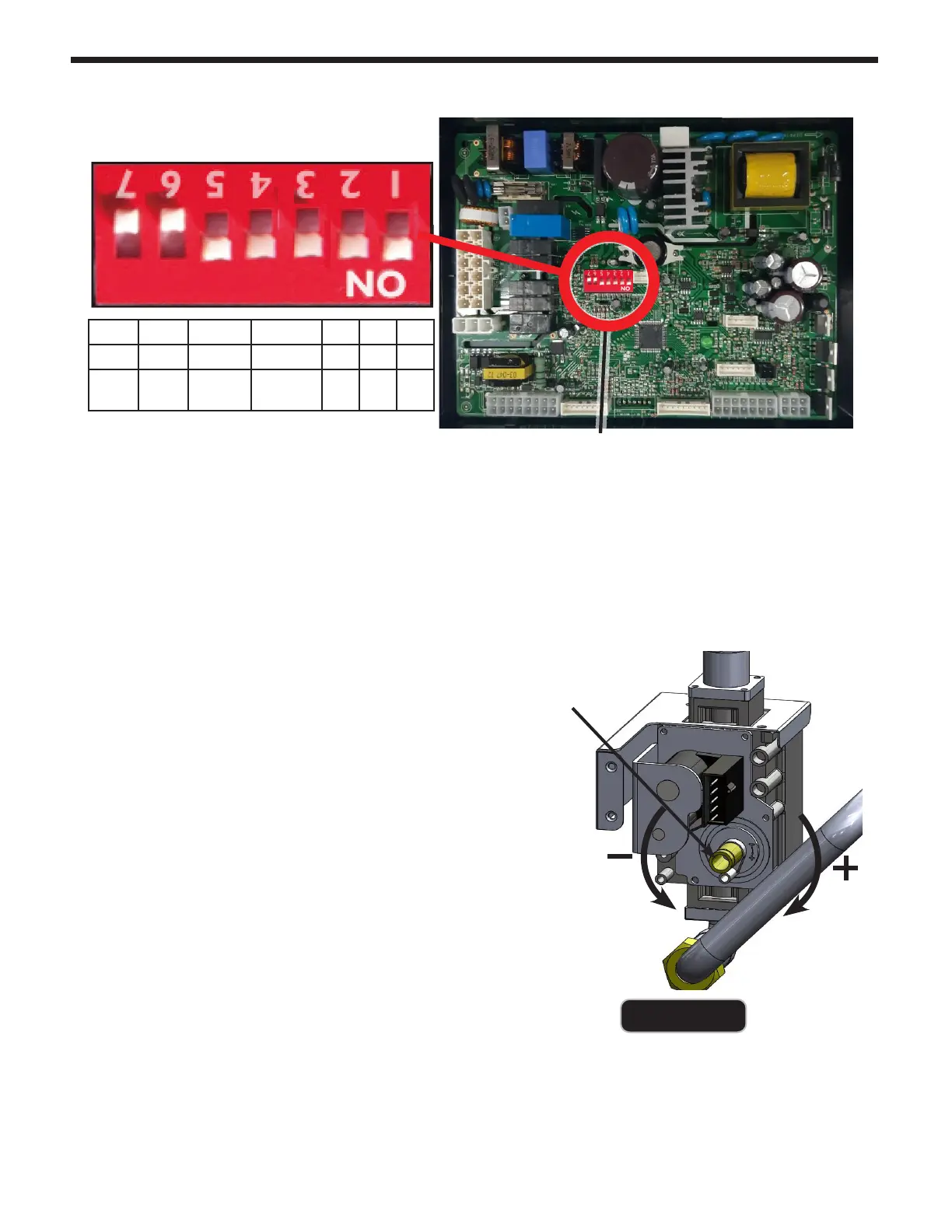

Table B DIP Switch Settings

Shown is a

Model 140

with 3" Venting

and using

Natural Gas

Figures E

MBH

140

199

ON OFF

MIN Fire Normal Operation

MAX Fire Normal Operation

NG Natural LP Propane

3” Vent Size

2” Vent Size

FTCW140

FTCW199

7. Install the new LP (propane) nozzle or orifi ce.

Re-use the packing from previous.

8. Return the Gas Inlet Pipe to its original position

and tighten both brass fi ttings.

9. Per Table B, set DIP Switch 5 to OFF for LP

Propane.

10. Turn ON the GAS and WATER supply to the FT

11. Now start the unit and adjust combustion as

described in Section 4.12

12. Upon completion of set up, write in the correct

Conversion Date and the Technicians Name to

the included gas conversion sticker. See Figure F.

Then apply that sticker adjacent to the rating plate.

4.15 Natural Gas to Propane Conversion (continued)

7. Install the new LP (propane) orifice. Re-use the

existing gasket. Install the LP orifice with its

identifying mark facing inward.

8. Return the Gas Inlet Pipe to its original position

and tighten both brass fittings.

9. Per Table B, set DIP Switch 5 to OFF for LP

Propane.

10. Turn ON the GAS and WATER supply to the FT

11. Now start the unit and adjust combustion as

described in Section 4.12

12. Upon completion of set up, write in the correct

Conversion Date and the Technicians Name to

the included gas conversion sticker. See Figure F.

Then apply that sticker adjacent to the rating

plate.

Figure E

Shown is a Model 199 Natural Gas

with 3” Venting.

Gas Valve

Adjustment Port

7* 6* 5 4 3 2 1

OFF OFF LP Gas 2˝ Vent

Low

Fire

High

Fire

Natural

Gas

3˝ Vent

FACTORY SET

*Dip Switches #7 and #6 are Maximum and Minimum re test

Switches which are used only when setting up combustion (See Section 4.13)

These Switches should only be in the ON position during either High or Low re

Testing. When nished testing, ensure both of these switches are in the OFF position.

Dip Switches #1, 2 and 3 are Set at the factory and should not need adjusting. For

Reference the correct positions of these three switches are as follows:

Model FTHF199 : All three dipswitches should be in the “down”/ ON position. As

shown above.

Table B

Dip Switch Settings

Loading...

Loading...