VS070QS-1618MDM1 Integrated Machine Mechanical installation

202403 (V1.0) 26

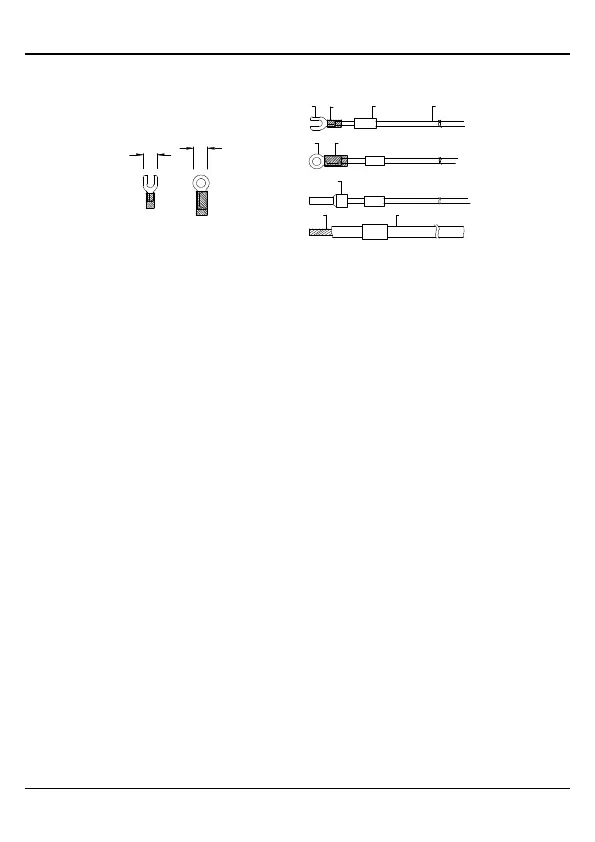

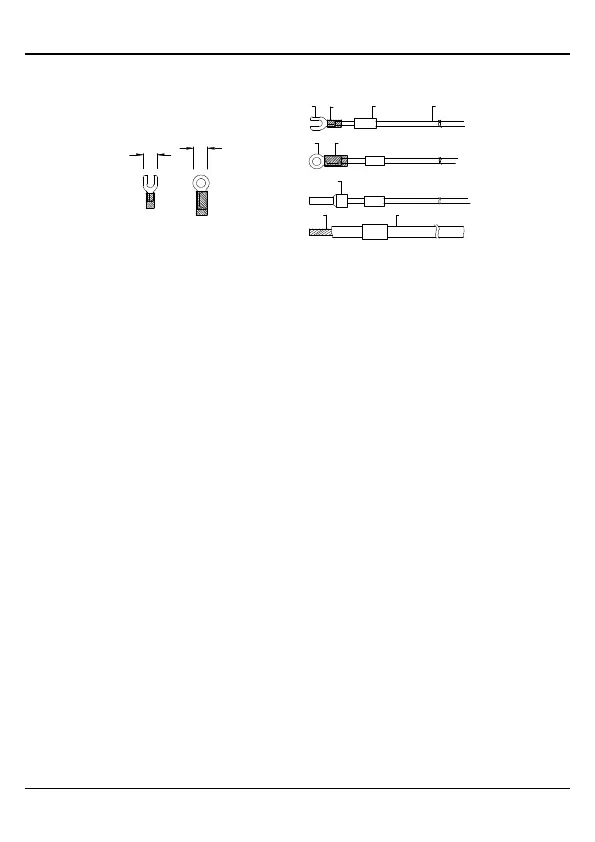

The recommended cable processing-method is shown in the following figure.

No more than

5.0

No more than

5.0

UT Cold-pressed

terminal

Heat-

shrinkable

tubing

Wire No. Wire

OT Cold-pressed

terminal

Heat-shrinkable tubing

H-type preinsulated

cold-pressed terminal

Hot tin-coated

cable terminal

Wire

PG

18

47

682

3.2 Power-on, operation, and routine maintenance

3.2.1 Power-on and operation

After the wiring is complete, check all the connections. Ensure that no foreign

matters have dropped inside the housing and heat dissipation is in good conditions.

The power-on procedures are as follows:

Step 1 Power on the PLC. The POWER indicator of the PLC is on.

Step 2 Start the Auto Station software on the PC and download the compiled user

program to the PLC.

Step 3 After the program is downloaded and verified, set the mode selection

switch to ON. The RUN indicator is on. If the ERR indicator is on, it indicates

that errors occur on the user program or the system. In this case, rectify

the errors by referring to the instructions in the

IVC Series Micro-PLC

Programming Manual

.

Step 4 Power on the PLC external system to perform commissioning on the

system.

3.2.2 Routine maintenance

Pay attention to the following aspects when performing routine maintenance and

inspection:

1. Ensure that the PLC operates in a clean environment, preventing foreign

matters or dust from dropping into the machine.

2. Keep the PLC in good ventilation and heat dissipation conditions.

3. Ensure that the wiring is properly performed and all the wiring terminals are

well fastened.

Loading...

Loading...