9.3 Leak Down Testing

Leak Down Testing can be performed manually or through an automatic test which displays pass or fail

results.

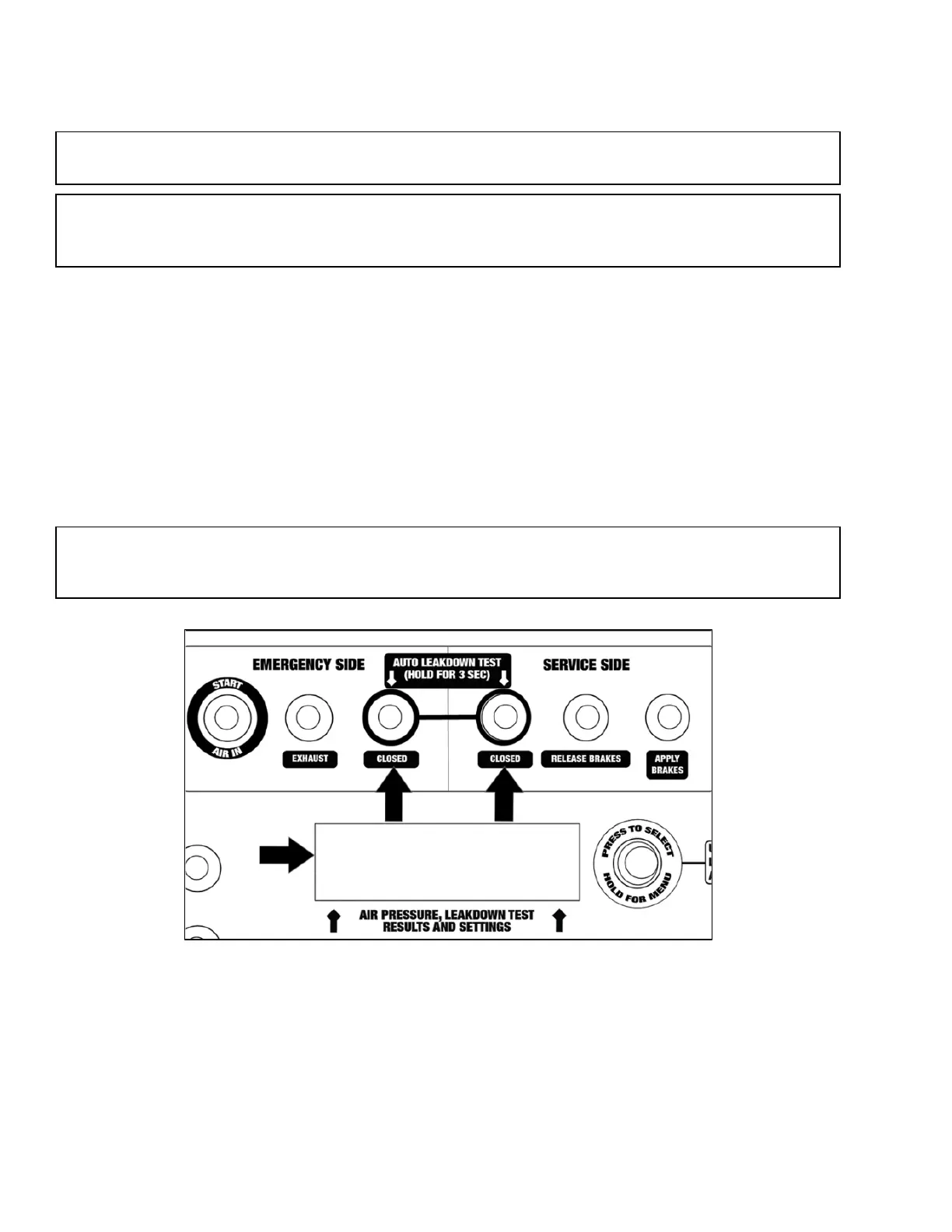

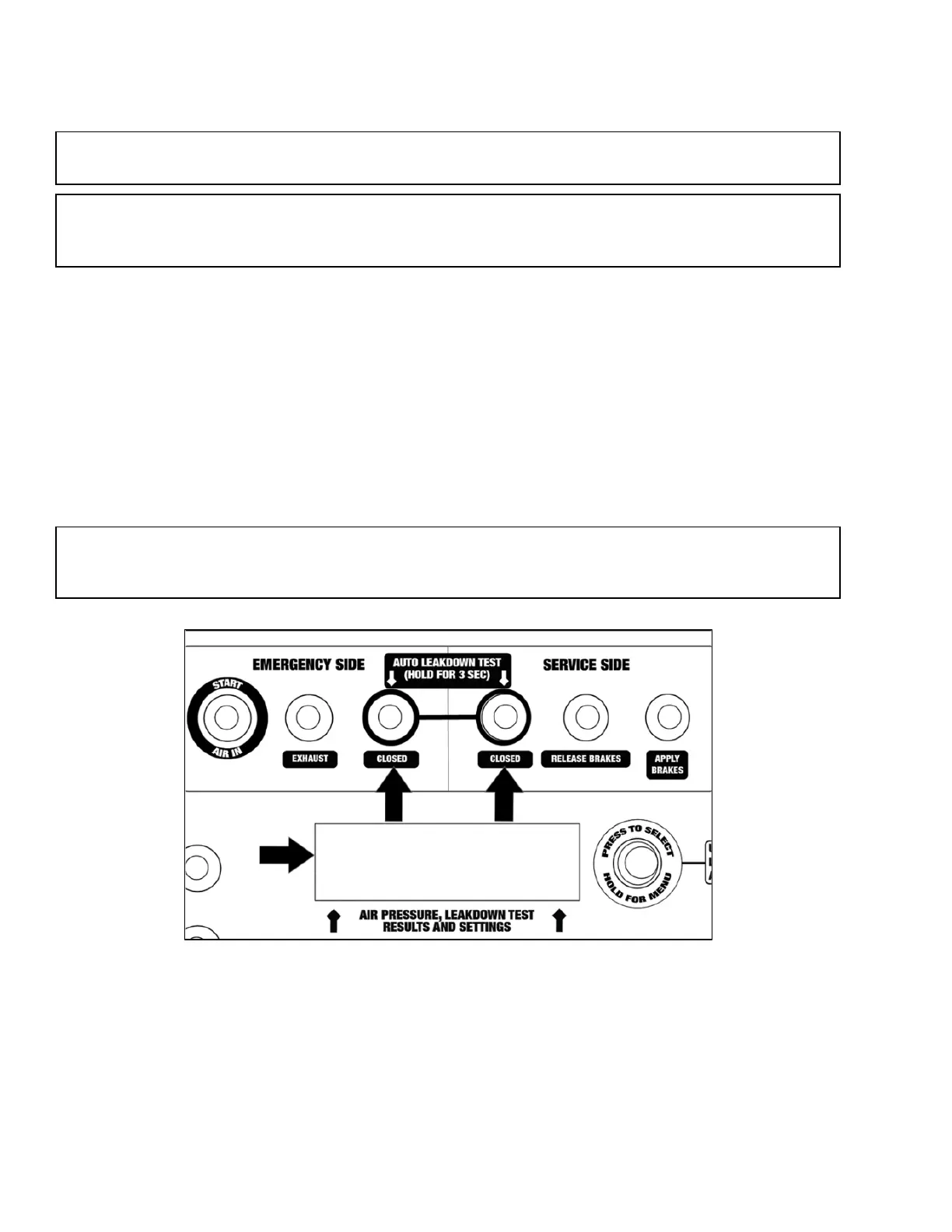

Manual Leak Down Test

A Manual Leak Down test simply means the user fills up one or both sides of a trailer’s air brake system

with air to the desired pressure, then stops the air flow and monitors the pressure loss over time by

viewing the real-time psi readings on the Upper LCD screen.

1. Complete the steps in sections 9.1 and 9.2.

2. 120 psi is the recommended testing value. Press the Close button on the Emergency side

and then on the Service side.

3. Use a countdown timer and observe pressure loss over time. Follow your company’s

recommended leak down tolerance to determine if the amount of pressure loss observed

falls within allowable limits.

EXAMPLE: Some fleets allow for 1 psi loss per minute. If the tester shows a loss of 2 psi after 3

minutes, the trailer passes the Leak Down test. If the tester shows a loss of 4 psi after 3 minutes, the

trailer fails the Leak Down test.

NOTE: The Alpha MUTT

®

is equipped with a safety feature which requires the user to acknowledge

the vehicle’s tires are securely chocked prior to resting. Until this is completed, the tester will not allow

operation of the air brake controls.

WARNING: DO NOT connect shop air until completing the testing set-up procedure. Failure to fully

understand these warnings can result in minor to serious injury and possibly death.

Loading...

Loading...