3

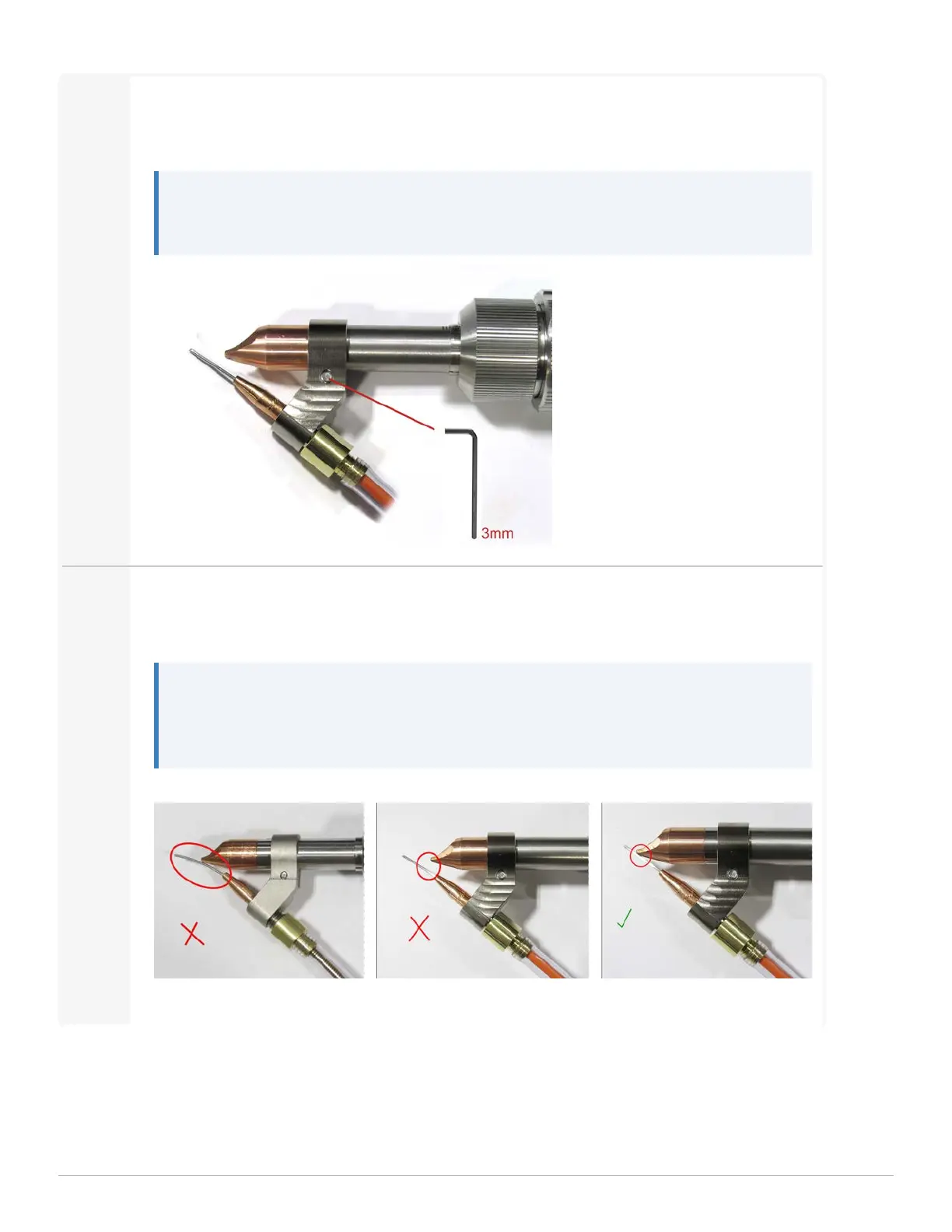

Attach the Weld Head Adapter by sliding it onto the tube.Use a 3 mm Allen Wrench to begin

tightening the screw. Do not tighten completely in order to make adjustments in the next steps.

Note: If you do not have metric allen wrench, the SAE 7/64'' can also be used. However, it

is best practice to use a metric allen wrench. Using SAE instead of metric will cause

stripping of the screw over time.

4

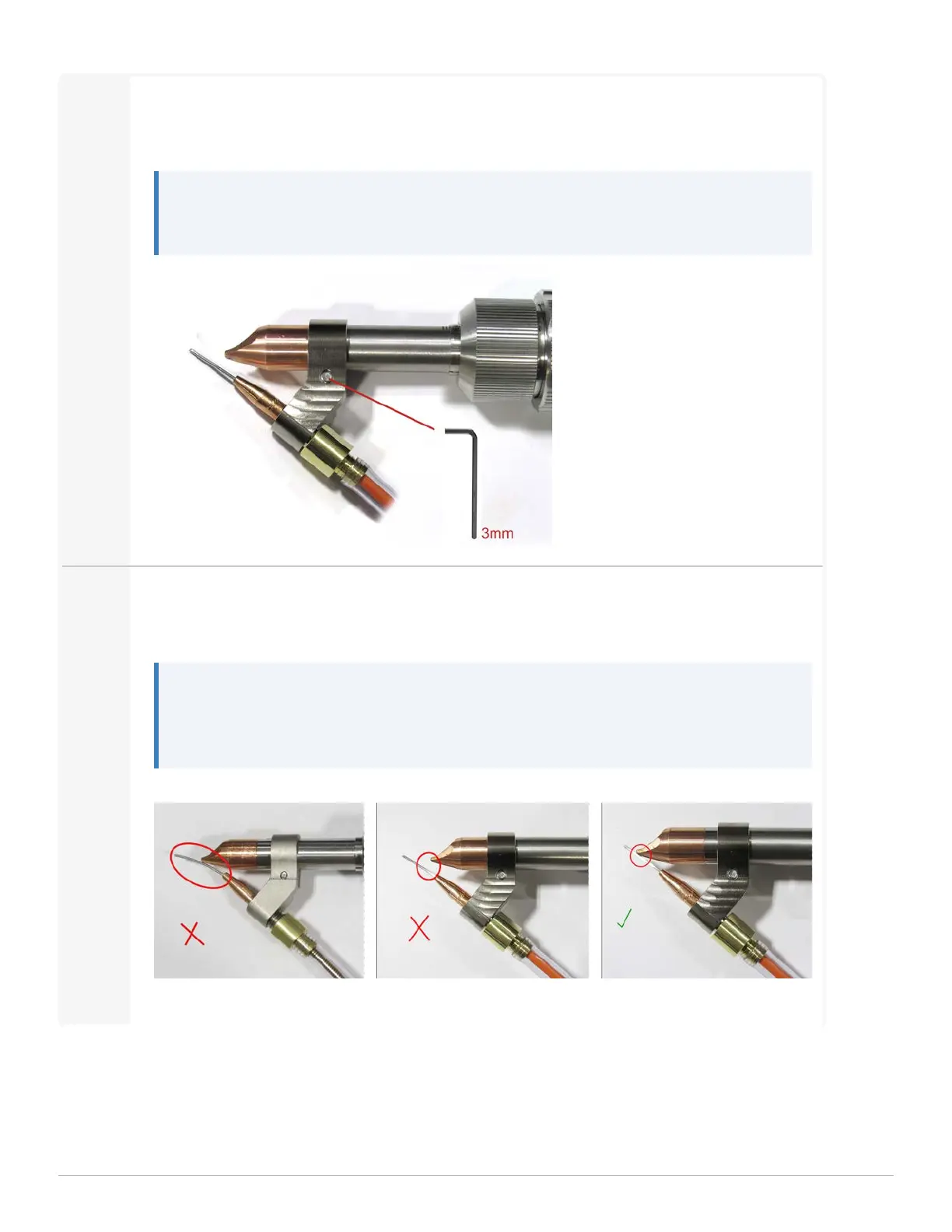

Ensure wire rests in the groove of the Nozzle. Tighten the Screw with a 3 mm Allen Wrench

once the wire is correctly positioned in the nozzle. The wire should maintain consistent contact

with the nozzle.

Note: The nozzle tip must touch the wire feed at all times. The wire should feed through the

grooved tip in a straight line. Too much tension of the wire against the grooved tip will feed

the wire in a curved pattern. To fix this adjust the Weld Head Adapter’s positioning on the

2.283'' (58mm) tube.

1 Getting Started

LightWELD WireFeeder Set-Up Guide

19

Loading...

Loading...