1 Getting Started

This guide describes the parts included in theLightWELDWireFeeder Kit, descriptions about the hard wire and soft wire

configurations, how to install the wire into the feeder through the nozzle tip, and instruction to synch with the LightWELD.

VIDEO: Part 1 - Getting Started

Configuration Options

Refer to the sections below to determine the appropriate components for your application. This will affect steps later in

the set up process. This wire feeder accepts standard 8" (203 mm)or 12" (305 mm)spools.

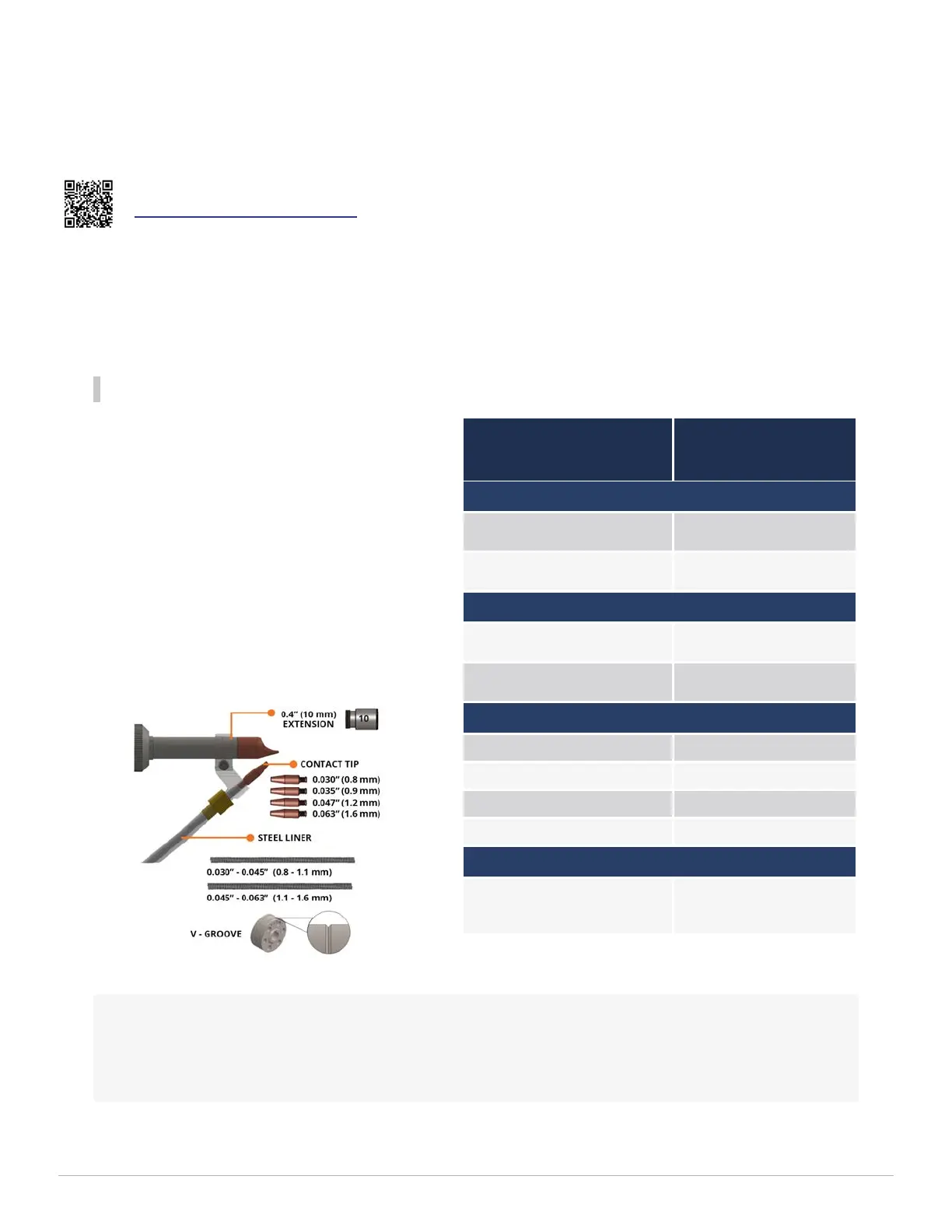

Hard Wire Configuration

Use the hard wire configuration for welding

metals, such as Stainless Steel,

Steel,Titanium, and Nickel alloys.

Requires V-Drive Rolls, Steel Liners, and 0.4''

(10mm) Extension, which is the default.

To select the proper components, use the size

that corresponds with the hard wire’s diameter.

See the chart on the right for reference.

Part Number

Corresponding Wire

Diameter

V-Drive Roll

CMMIXXX0002838PX

0.030”-0.035”

(0.8-0.9mm)

CMMIXXX0002839PX

0.045”-0.063”

(1.1-1.6mm)

Steel Liner

CMUS0010363X01XU

0.030”-0.045”

(0.8-1.1mm)

CMUS0010363X02XU

0.045”-0.063”

(1.1-1.6mm)

Contact Tip

CMUS0011444XXXX0 0.030” (0.8mm)

CMUS0011445XXXX0 0.035” (0.9mm)

CMUS0011446XXXX0 0.047” (1.2mm)

CMUS0010319XXXXU 0.063” (1.6mm)

Extension

CMUS0008377XXXXU

The default 0.4"

(10mm) extension is

used for all hard wire.

Example: To do a Stainless Steel filler weld with 0.045” (1.1mm) Hard wire, use the 0.045”-0.063” (1.1-

1.6mm) V-Drive Roll, the 0.030”-0.045” (0.8-1.1mm) Steel Liner, the 0.047” (1.2mm) Contact Tip,

and the 0.4'' (10mm) Extension.

1 Getting Started

LightWELD WireFeeder Set-Up Guide

1

Loading...

Loading...