Installing the pneumatics

WARNING

Risk of injuries through leaking compressed air and

lashing pneumatic hoses

Open or loose pneumatic connections can cause

severe injuries.

Ensure that during installation and maintenance of

the pneumatic hoses and of the compressed air

regulator compressed air is not conducted through

the hoses and connections.

Before conducting compressed air through the

hoses and connectors, verify that the hoses are

securely inserted into the correct connectors and

that they are not damaged. This also applies to the

compressed air regulator.

Do not conduct compressed air through damaged

hoses and connectors.

NOTICE

The spindle may suffer bearing damage and electrical

damage if the compressed air is contaminated

The incoming compressed air must be dry and oil-free

according to ISO 8573-1:2010 because the

compressed air regulator only serves as an indicator

for contaminated air.

Air purity according to ISO 8573-1:2010

Solid

matter

particles

class 3 Filtration degree better than

5µm for solid particles

Water class 4 Maximum pressure dew

point: +3°C (37.4 °F)

Maximum

oil content

class 3 Maximum oil content

1mg/m

3

Ensure that the compressed air meets the above

requirements.

Only connect the machine to the compressed air

supply if the compressed air regulator is properly

installed.

Connect the machine to the compressed air supply

only via the provided compressed air regulator.

You can find specific values and additional require-

ments in the chapter on technical data.

Technical

data

– on page13

The machine requires the compressed air for the

following tasks:

n For the opening and closing of the collet chuck

during tool changes.

n For the spindle sealing air which prevents foreign

bodies from entering the spindle.

n For the sealing air in the working chamber that

keeps machining debris away from sensitive

machine parts.

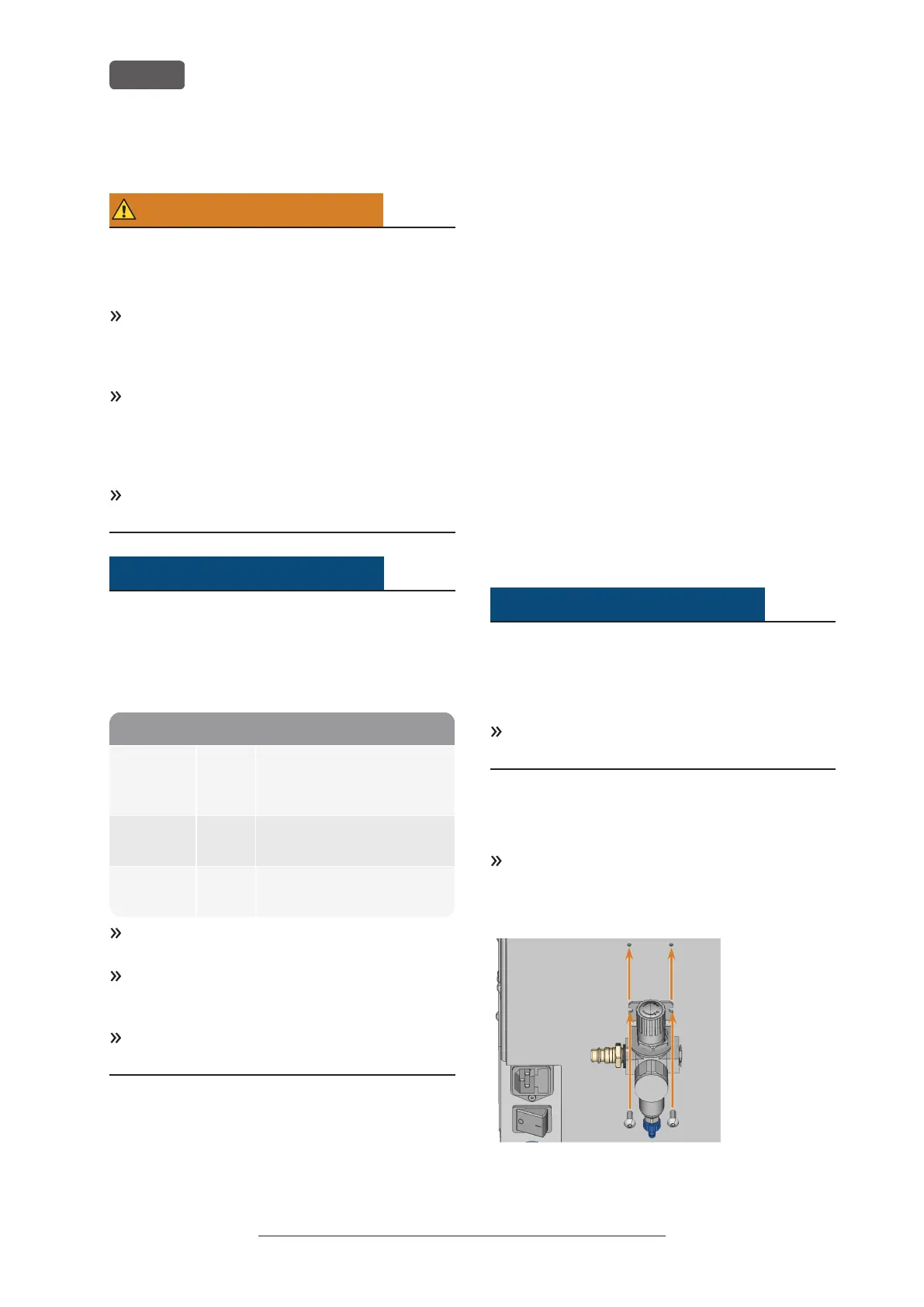

Overview compressed air regulator

The machine is connected to the external air supply

via a compressed air regulator. You can use this regu-

lator to monitor and regulate the pressure of the

incoming air.

The compressed air regulator is supplied with the

machine and needs to be mounted on the side of the

machine housing when installing the machine. The

regulator has the following connections:

n 1/8” internal thread, fitted with male compressed

air connector to connect the external compressed

air supply

n 6 mm push-in fitting to connect the machine.

NOTICE

Failure of the water separator caused by a wrong

alignment of the compressed air regulator

The compressed air regulator must always be

mounted in an upright position because otherwise

the water separator will not work.

Mount the compressed air regulator in an upright

position.

On the left side of the machine are two bores which

you can use to mount the compressed air regulator on

the machine.

Mount the compressed air regulator in an upright

position, using the oval-head screws provided in

the bores.

FIG. 11 – MOUNTING THE COMPRESSED AIR REGULATOR

Operating Instructions:PrograMill Dry

Version: 11/19/2020

PrograMill Dry – Installing the machine

EN 18

Loading...

Loading...