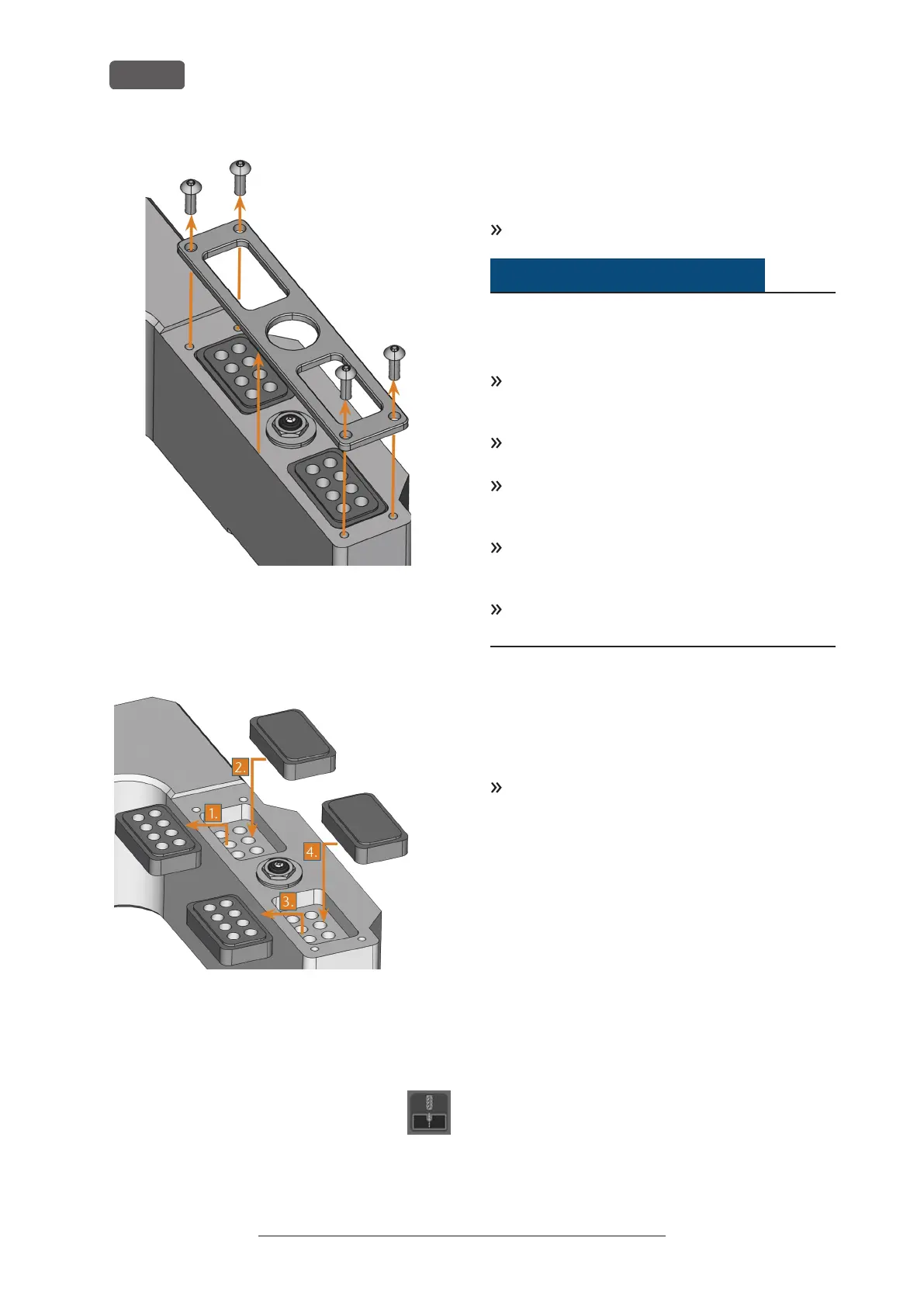

FIG. 34 – UNSCREWING THE SCREWS AND LIFTING THE

COVER

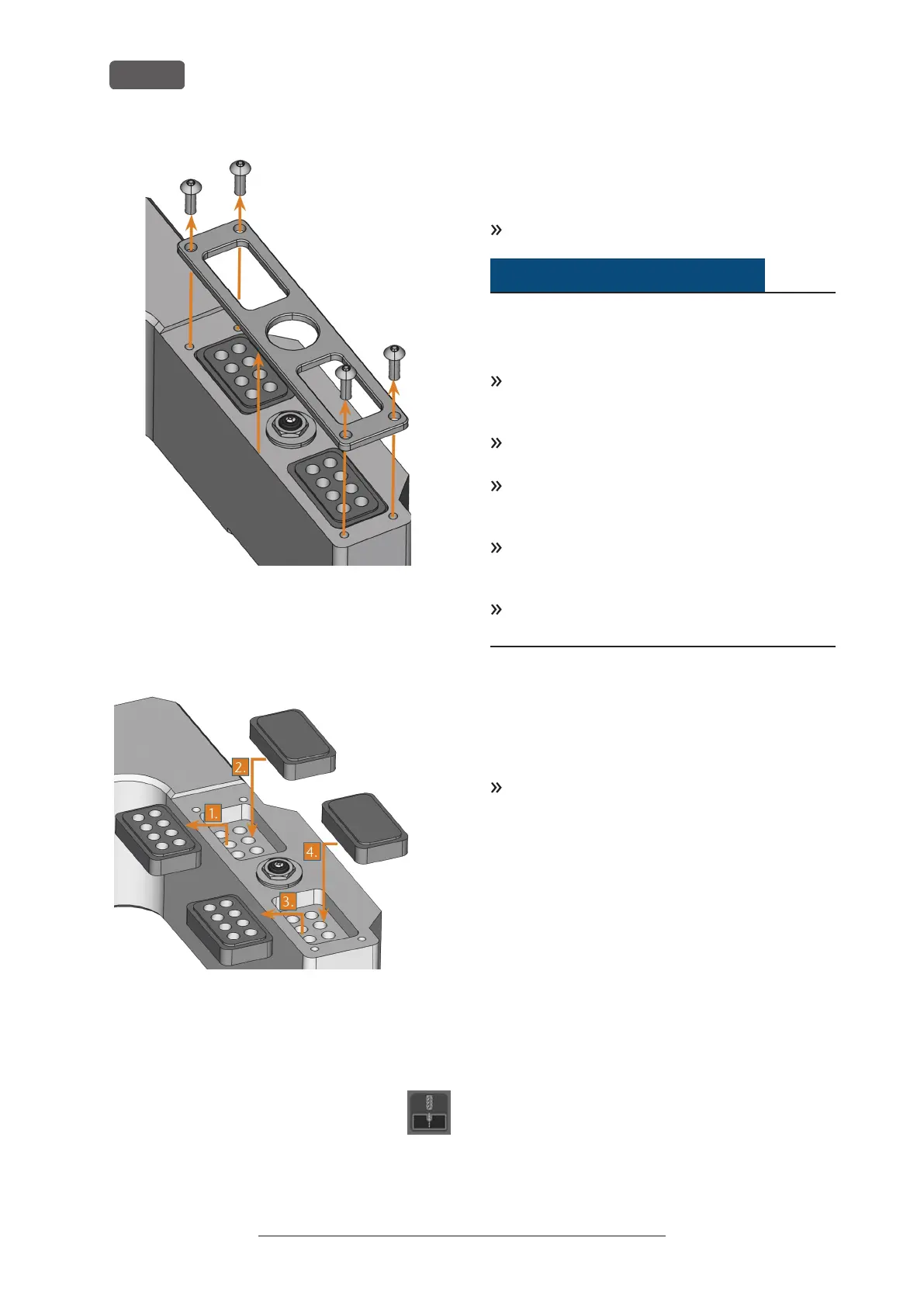

5. Remove the 2 existing tool magazine inserts and

replace them with 2 new ones.

FIG. 35 – NEW TOOL MAGAZINE INSERTS (RIGHT,

WITHOUT TOOL POSITIONS) REPLACE OLD INSERTS

(LEFT, WITH TOOL POSITIONS)

6. Put the cover back onto the tool magazine and

screw it down.

7. Insert the supplied drill bit for tool posi-

tions into the spindle and start the

drilling process by clicking the flowing

button PrograMill CNC.

Updating the software and firmware

Updating the manufacturing software and the firmware

is an interdependent procedure.

Be sure to read all information in this chapter.

NOTICE

Damaging of the control unit when a firmware update

is interrupted

If the firmware update is interrupted, the control unit of

the machine may become permanently damaged.

Only update the firmware if a permanent electrical

supply of the machine and the computer is guar-

anteed.

Only update the firmware if the computer's oper-

ating system is stable and is free of malware.

Only update the firmware if the connection

between the computer and the machine is stable.

Always use a wired connection during the update.

Do not disconnect the machine or the computer

from the electrical source nor switch off the

machine or computer during a firmware update.

Do not close PrograMill CNC during a firmware

update.

Updating the manufacturing software

PrograMill CAM and PrograMill CNC are updated regu-

larly.

Ask your service partner for the latest installation

package.

To update PrograMill CAM and PrograMill CNC, fol-

low the instructions in the documentation for the

manufacturing software.

1. Change to PrograMill CNC on the CNC computer.

2. Start PrograMill CNC

Updating the firmware of the machine

The firmware is the internal control software of your

machine. New versions may introduce new functions

and improve existing ones. New firmware versions

come as part of new versions of PrograMill CNC.

Operating Instructions:PrograMill Dry

Version: 11/19/2020

PrograMill Dry – Maintenance and do-it-yourself

EN 36

Loading...

Loading...