-6-

After draining the oil, tighten the oil drain

sc

rew 0 .

5. Periodi

ca

lly

wipe

away any oil which

co

llects

in

the r

ear

bed oil s

ump

0 with a cloth.

6. Turn the machine pulle

y,

so that the o

il

hole

cove

r @ is facing

up

ward, and then remove the o

il

h

ole

cover

@

and fill the oil tank

0 with oi

l.

If

the l

eve

l

of

lubricating

oil

drops below the middle reference line 0

on

the oil tank, no oil will thus not be lu-

bricated sufficiently. Be sure to maintain the lubri

ca

ting oil level

at

a l

eve

l above the center

ref

eren

ce

line.

7. Attach the o

il

hole cover @ .

*

if

the machine is being u

se

d with lhe pull

er

atlached remove the

cove

r screws

G)

and

fill with o

il

until the l

eve

l

reach

es

the upper referen

ce

line in the o

il

sig

ht

glass.

If the o

il

level drops to the l

owe

r reference line, be sure to add m

ore

oil.

After lubrication is

co

mpleted, tighten the

cove

r scr

ew

G)

.

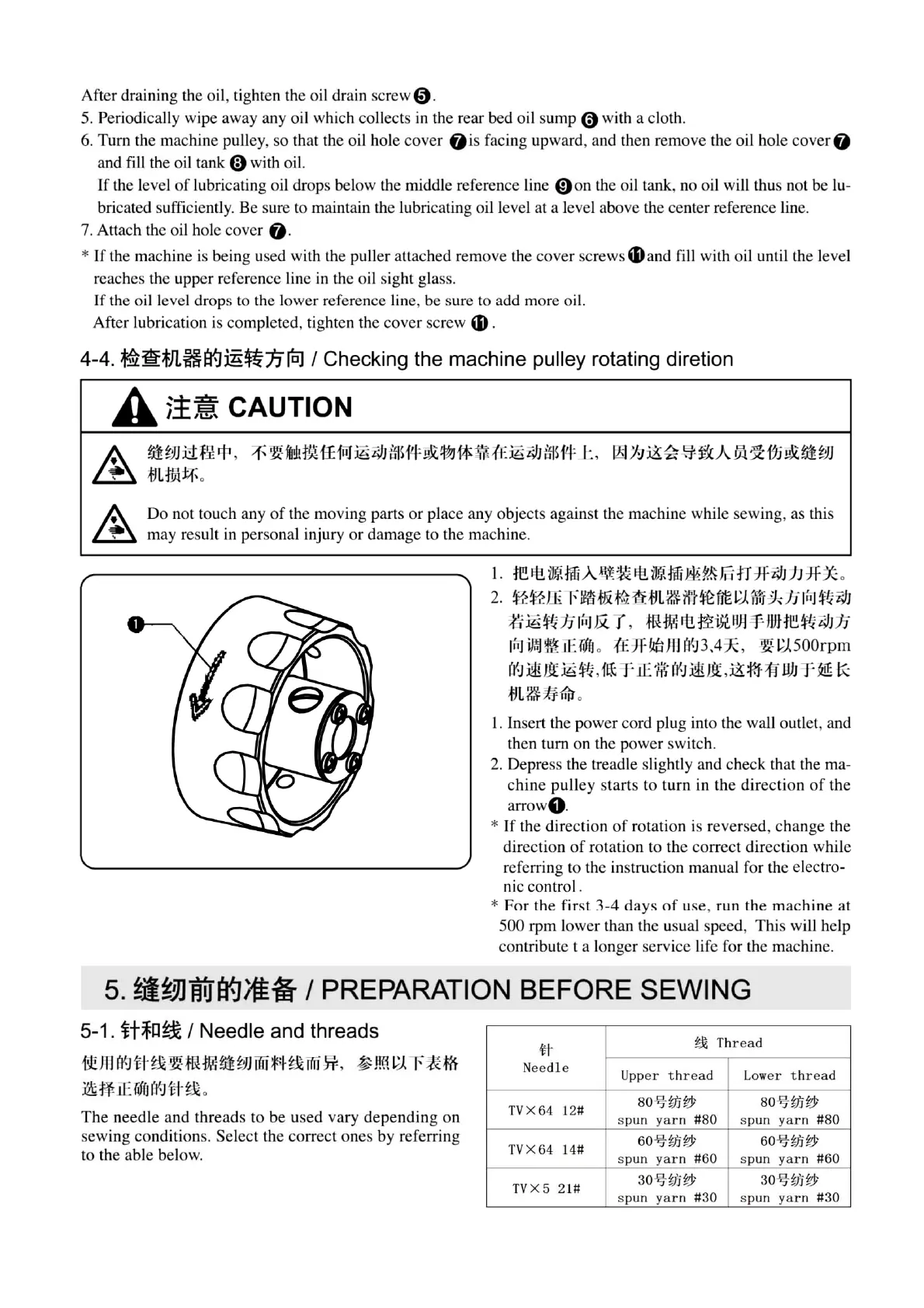

4-4. ~~fJtfftr-JiE~:nioJ I Checking the machine pulley rotating diretion

A

ft~

CAUTION

awM~~

.

~~~mff~~~$~~~~

a

n~~$~~.

~h~*~•Am~m~aw

tJU.6:itr-

.

Do n

ot

touch any

of

the moving parts

or

pl

ace

any objects against the machine while s

ew

ing, as this

m

ay

result in per

so

nal injury or

damage

to

the machine.

l .

re%

iJff,

n1L

A

~

~

It! fit

ffff

w.

r,Mf

HT

:;Jf

z;/

J)

HF

.k.

2.

!i1.

$?.

Bi

Fl

l1HJi

¥}

~

fJL~

t!

Ht

00

~J

%1

.:J,

}j

l

wJ

~"

z;/

J

~

:i6

~

Jj

l

iIJ

Jx

( , ffi

~

it

rt~

194

T

JVH~

4"-t

4'J

Jj

l•

1

J

iJ.'d~

1Ef

ef

(J

.

11:Jf!itiJI

I

!]{J3,4:;R

, ~ ~

J500

rpm

(i

J i£

Ht~~

,

fkt

T iE ·,

ip;

t

(-.1

i£

JJt,

:i!

:r.J-

ff

ilJJ

T

~

K:

m~

J.r

ftl?

.

l. Insert the p

owe

r cord plug

int

o the wall outlet, and

then

tum

on the p

owe

r

sw

itch.

2.

De

pre

ss the treadle slightly and c

he

ck th

at

the ma-

c

hin

e

pull

ey

s

tarts

to

turn

in

th

e

direction

of

the

arrow

O .

*

If

th

e

dir

ec

tion

of

rotation is r

everse

d, ch

ange

the

direction

of

rotation

to

the

co

rre

ct

dir

ect

ion while

r

efe

rring to the instruction ma

nu

al for the electro-

nic control.

*

For

th

e

fir

st 3-4

days

of

u

se,

run

the

m

ac

hine

at

50

0

rpm

l

owe

r than lhe usual speed, This will help

co

ntribute t a lon

ger

se

rvice

li

fe for the m

ac

hine.

5.

~t11.JfiJa{])i§ I PREPARATION BEFORE SEWII

NG

5-1

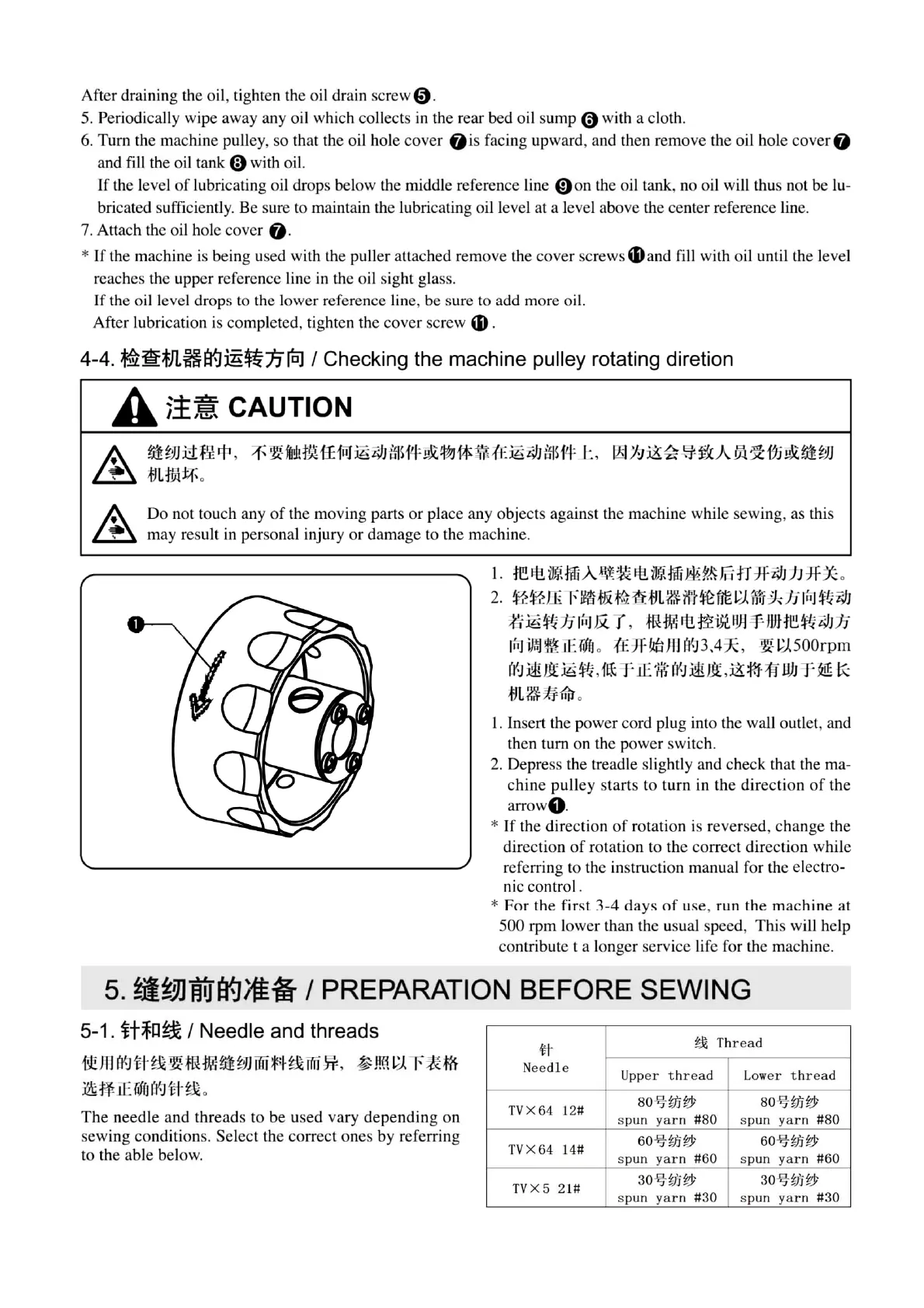

. it~n~ I Needle and threads

i!l!Jrl

IY-J

tt

tit~

m

~a;,]]

llU

" ~

t:lH

IIT

ff

'

~

$~

~

r

~ ~

~

ff. Jf

(d(1

W;_i

H ~i.

The

n

eed

le and

thr

ea

ds to be u

sed

vary

depending

on

sewing

co

nditions. Select the correct ones by referring

to the able below.

tt

N

ee

dl

e

TV

X 64 12#

TVX64 14#

TV

X 5 21#

~

Thr

ead

Upper

thr

ead

Low

er

thr

ea

d

80

%~~

80

%~

~

sp

un

yar

n #80 spun

yarn

#80

60

%~~

60

%~

~

sp

un

yarn

#60

spun

yarn

#60

30

%~~

30

%

~~

sp

un

yarn

#30 spun

yarn

#30

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

Loading...

Loading...