tecMIG 450/600

Operating manual Page 48

33. Welding torch with Display / Job - sequence

Warning: Switch off the machine for changing the torch !!

Functions (sorted by the control box):

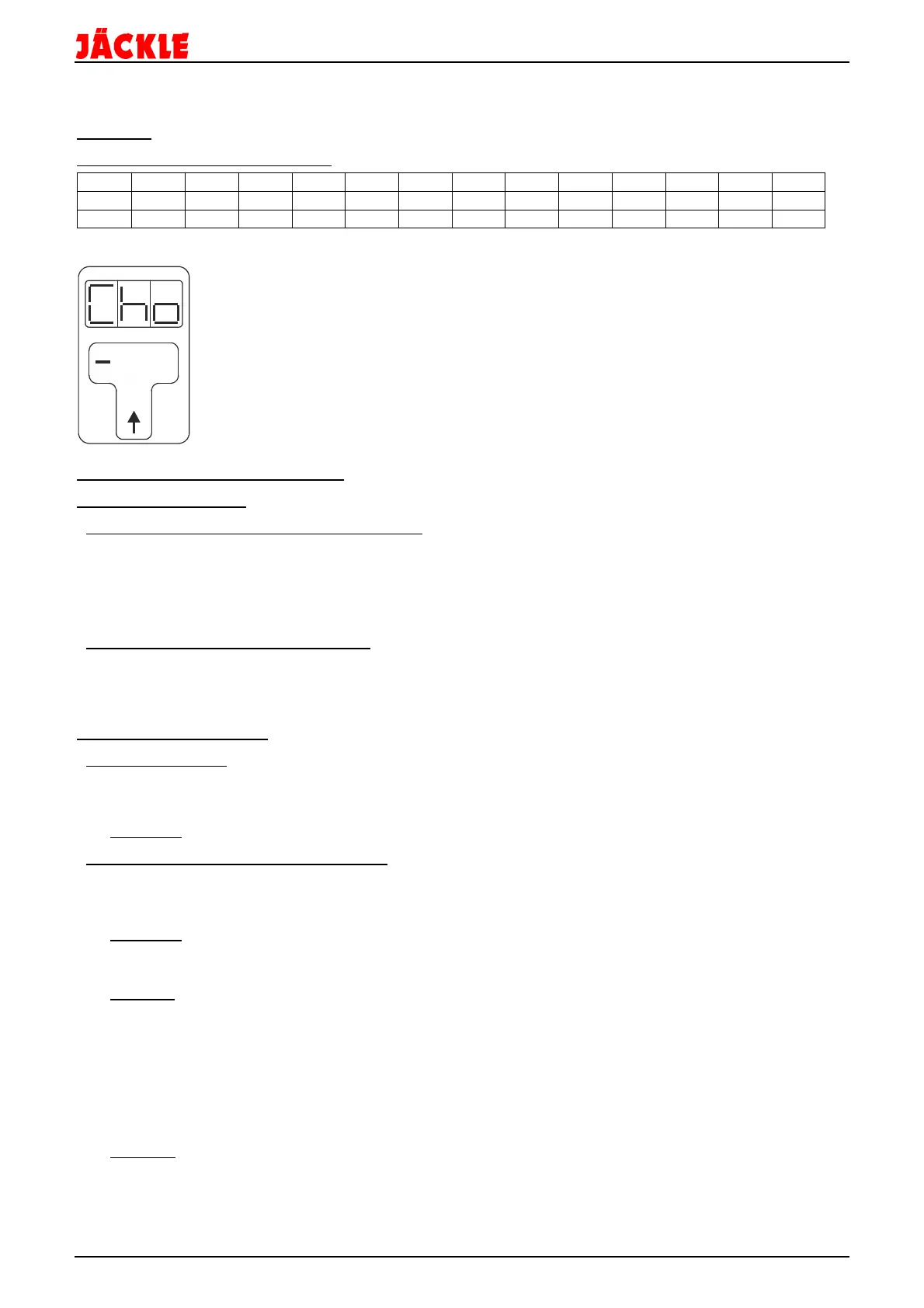

Hnd Cor Sol Mod Cho Sts bUb PrG PoG Job CSC CEC Spt

MC 1

■

■

■

*

■

■

■

■

■

■

■

■

■

■

MC 2

■

■

■

*

■

■

■

■

■

* This function is active during welding!

Hnd

= Hand welding,

Cor

= Voltage correction (Automatic welding),

Sol

= Power,

Mod

= Mode (see below),

Cho

= Choke,

Sts

= Startspeed,

bUb

= Burn back,

PrG

= Pre gas time,

PoG

= Post gas time,

Job

(see below),

CSC

= Crater start current,

CEC

= Crater end current,

Spt

= Spot time

(CSC and CEC only active with crater function)

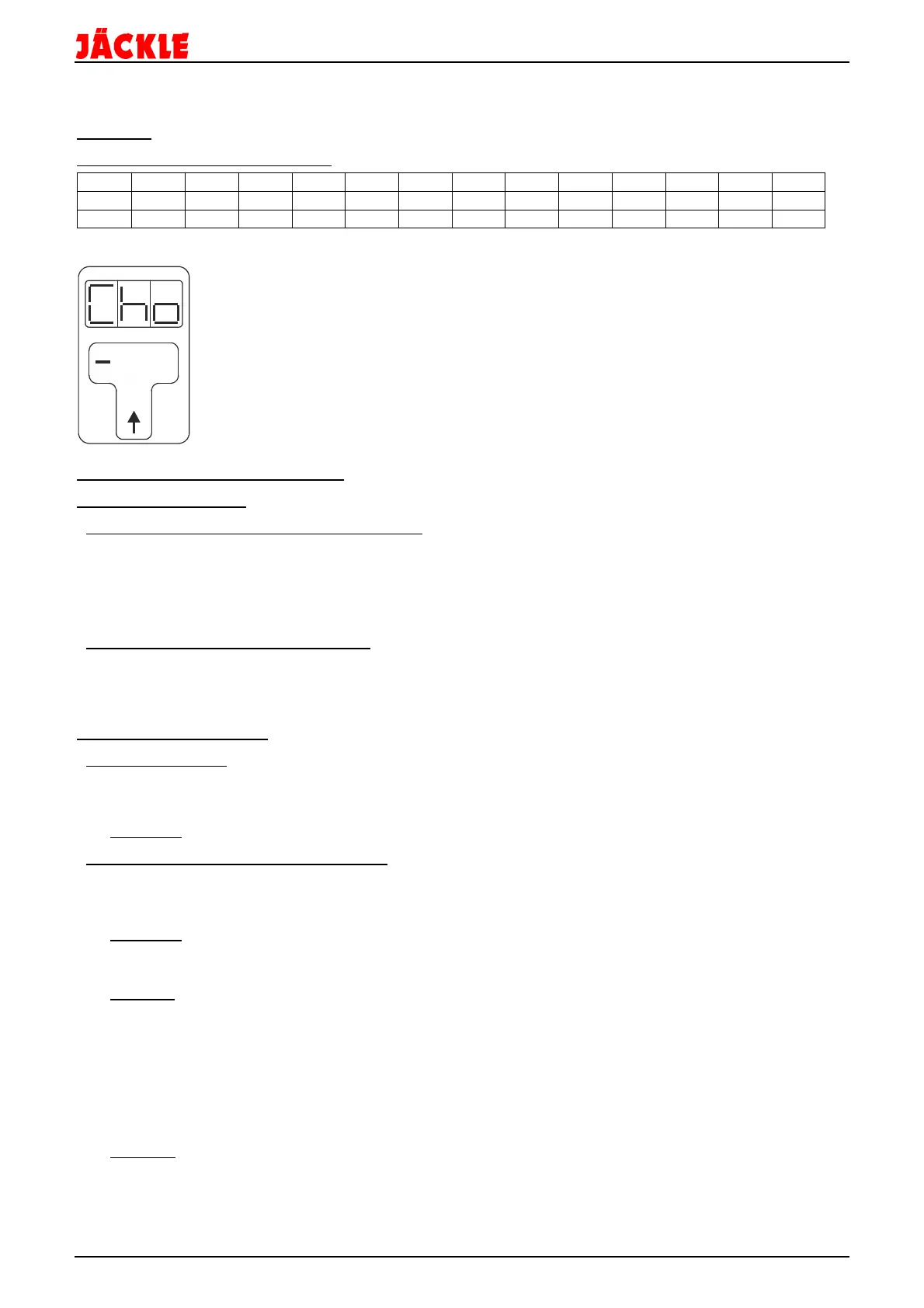

Tapping on the arrow button will switch between the different functions.

The value can be changed by using the + and – buttons.

The changes are displayed simultaneously on the MC control box.

Functions with extended selections:

Function MODE (Mod):

- Mode 2-cycle / 4-cycle / spot – crater (only MC 1)

Display ‚Mod‘

Use the

- button

to switch between

2-cycle (2)

or

4-cycle (4)

function.

(Indication in the left display

2

or

4

)

Use the

+ button

to switch between

normal operation

(

-

),

spot welding

(

S

) or

crater function

(

C

).

(Indication in the right display

–

or

S

or

C

)

- Mode Automatic welding or Hand welding

Display ‚Mod‘

A long press of the

– button

will change between

Automatic (A)

and

Hand (H)

welding.

(Indication in the middle display

A

or

H

)

Function Job (only MC 1):

- Calling a Single Job:

Press the arrow button repeatedly until ‘Job’ appears on the display.

Select the desired job number using the + or - button and confirm by pressing the arrow button.

The job, e.g. Nr. 2 is selected (= in display).

Comment:

=

Job selected,

u

Job number occupied,

F

Job number free

- Save multiple jobs in a sequence and recall:

It is possible to store several jobs behind the other to move during the welding process between the

individual jobs back and forth. This is useful, for example, if a part must be welded with different welding

power, but the welding process should not be interrupted.

Comment: The jobs must all be of the same wire diameter and gas type.

But it is possible to use standard MIG/MAG and Power in the same sequence.

The job sequence must always be limited by a free job at the beginning and end.

Example:

Job 1

– free,

Job 2

- MIG 160A,

Job 3

- Power 250A,

Job 4

- MIG 100A,

Job 5

– free

In this example, it is possible to change during welding between the welding jobs 2, 3, and 4 by

using the + and - buttons.

It is possible to store several of these job sequences.

They must always be enclosed by a free job.

To activate a job sequence, a job from this sequence must be selected and called up by pressing the

arrow key. When the display of the torch is switched back to the normal display (after 3 seconds), it is

possible to select between the jobs using the + and - button.

Attention: If there is an error in the sequence (e.g., different gases / material), the job sequence cannot

be activated.

To reset the + / - buttons for the power control during welding, open the Job menu and select a free job

e.g. (F 1) and confirm it by pressing the arrow key.

Loading...

Loading...