tecMIG 450/600

Operating manual Page 51

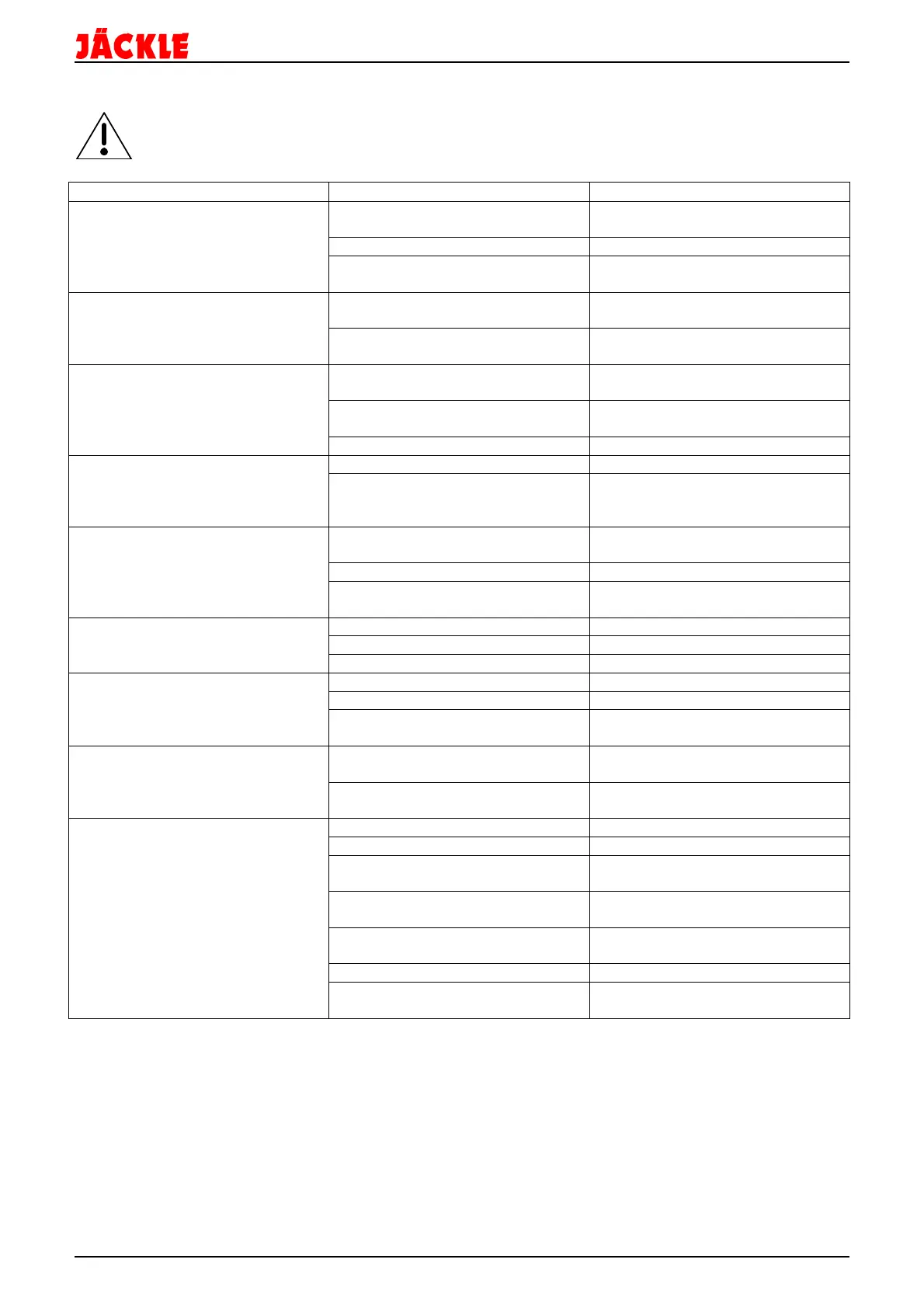

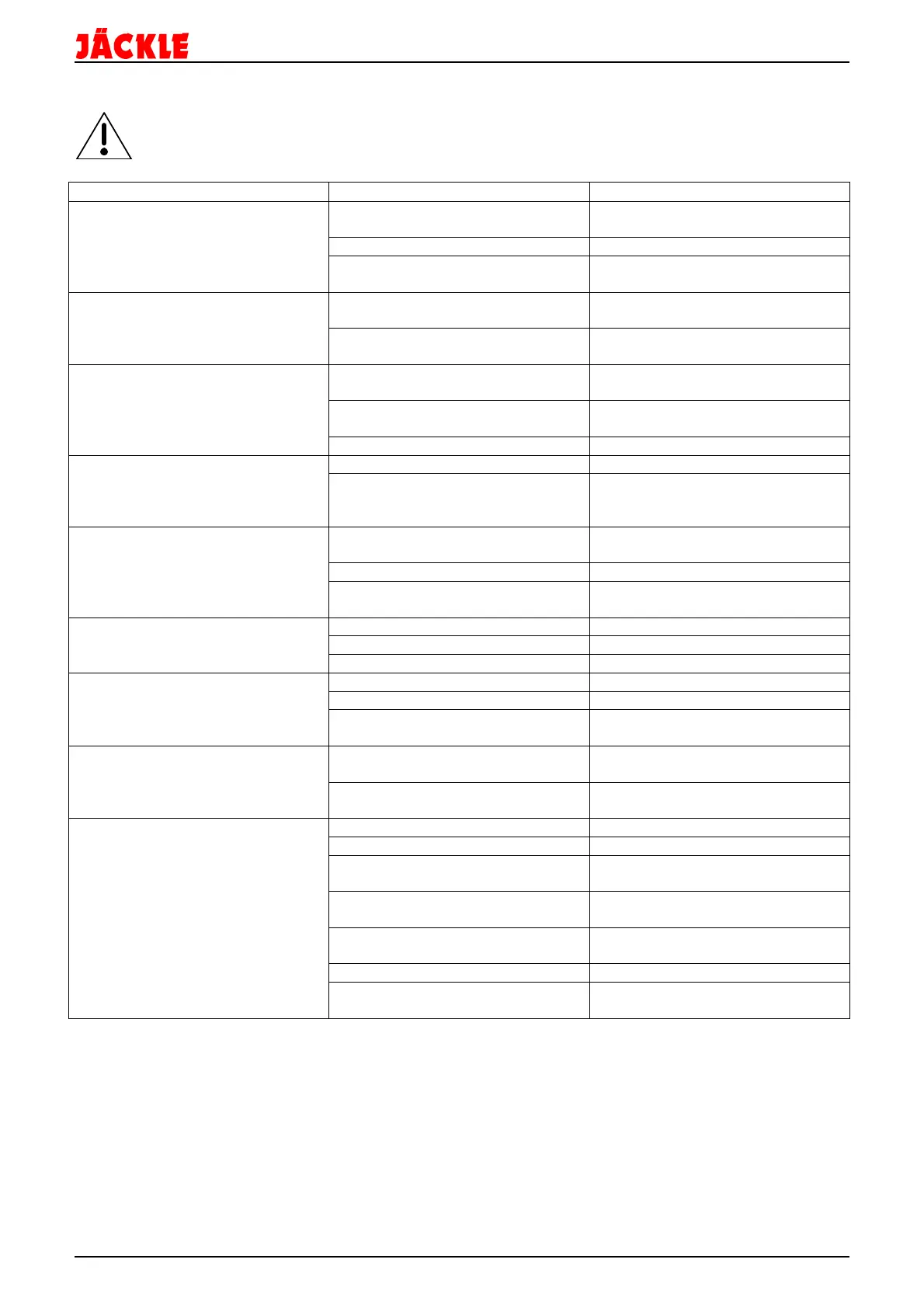

37. Trouble - shooting

Any remedial action to defective electrical equipment must be carried out by a qualified electrician!

Malfunction/error Cause Remedy

Display

T°C – 01/02/03 – hot

Engine overheated

(See Point 31)

Machine to cool down with a

running fan

Thermal sensor line interrupted Look for and eliminate interruption

Wrong type of machine in the

control box set

Contact service partner

Display

T°C – int – e.g. +56

(See Point 20)

Ambient temperature below -10 ° C

or above +50 ° C

Bring Machine into normal

temperature range

Thermocouple defect in the control

box

Change control box

Sensor repaired

Display (continuously)

Err H2o ---

(To clear switch machine off and

on)

Water tank empty Fill in cooling water with alcohol in

the ratio 4:1

Water flow below 0.25 l / min Check water flow

Torch / pipe

Flow meter is defective Flow meter exchange

Main switch ON

1 or 2 green Indicator lights on the

front plate are not lit

(see control elements)

Failed one or more system phases Check main supply and fuses

Fuse in the front plate defective Change fuse 2A slow

Main switch ON

Green control lamps are light

Control box MC without function

Secondary fuse on auxiliary

transformer defective

Change fuse 6,3A slow

Fuse in control box MC defective Change fuse 6,3A slow

Cable in torch hose pack defective

/ broken

Check 5 pole cable

No function after pressing torch

trigger key

Torch trigger defective Change torch trigger

Torch control line interrupted Check torch control line

Control box MC defective Change control box

Fire feed motor out of service Control box MC defective Change control box

Fire feed motor defective Change wire feed motor

Wiring between control box and

Motor interrupted

Check wiring

Wire buckling between wire feed

rollers and guide tube

Pressure of the wire feed rolls to

big

See chapter 30

Distance from wire feed rollers to

guide tube too far

Check distance / realign wire guide

tube

Irregular wire feed Bad uncoiling of wire Check / refit wire coil

Wire-holding arbour runs heavily Check wire- holding arbour

Wrong wire feed roller Use the right wire feed roller

See chapter 30

Dirty / defective wire guide tube or

spiral

See chapter 30

Cogged / defective current contact

tip

Clean / exchange current contact

tip

Dirty/ rusty welding wire Exchange welding wire

Wire guide tube misaligned with

wire feed roller groove

See chapter 30

Loading...

Loading...