Model LJ Pool and Spa Heater

Page 39

open end of a burner. When the gas flows into the

burner, a “negative” pressure is created at the opening

of the burner. This negative pressure pulls air into the

burner with the gas and mixes the two together. As

the gas/air mixture flow through the burner ports it is

ignited in the combustion chamber. Hot combustion

products then raise through a highly efficient heat

exchanger. Combustion products then enter a flue

collector and are directed to the outdoors through the

grate top of the heater or a vent pipe and cap.

10.3 Heater Components and Their

Operation

1. Gas valve / Regulator - The gas valve controls

gas flow into the manifold. It provides flow only

when the temperature controls require heat and

only if all safety controls enable operation. It is

also a positive pressure regulator. It regulates

the gas pressure in the manifold to specifications

addressed earlier in this manual. This is neces-

sary for proper operation of the burner system.

2. LJ Temperature Control/Ignition Control

Combination System-

a. Temperature Control-The Jandy LJ

controller is an electronic control which senses

water temperature by means of a thermistor and

controls heater operation to bring the water to the

temperature selected. It has an option for two

separate thermostat settings which are typically

used to set pool and spa temperatures. A push-

button selector key is used to switch between

settings.

b. Ignition Control - The ignition control is

integrated with the temperature control. It

provides energy for ignition of the air/gas mix-

ture, monitors the flame and controls the gas

valve. When the temperature control requires

heat, the ignition control provides a pre-purge of

the combustion chamber. Then it applies electri-

cal power to a “hot surface” igniter. When the

igniter is hot enough, the ignition control opens

the gas valve. It has sophisticated means to

sense ignition and flame condition so that un-

burned gas will not escape. After the burner is

shut off, the ignition control continues operation

to provide a post-purge period.

3. Igniter - The hot surface igniter is a ceramic

composite element which becomes very hot

when electrical power is applied to it. The hot

surface igniter directly ignites the air/gas mixture

in the combustion chamber.

4. Flame Sensor - The flame sensor is the elec-

trode through which the ignition control detects

“rectification” of current passed through the

flame. Inadequate rectification indicates an

unsatisfactory flame condition. The ignition

control responds to the flame signal provided by

the flame sensor.

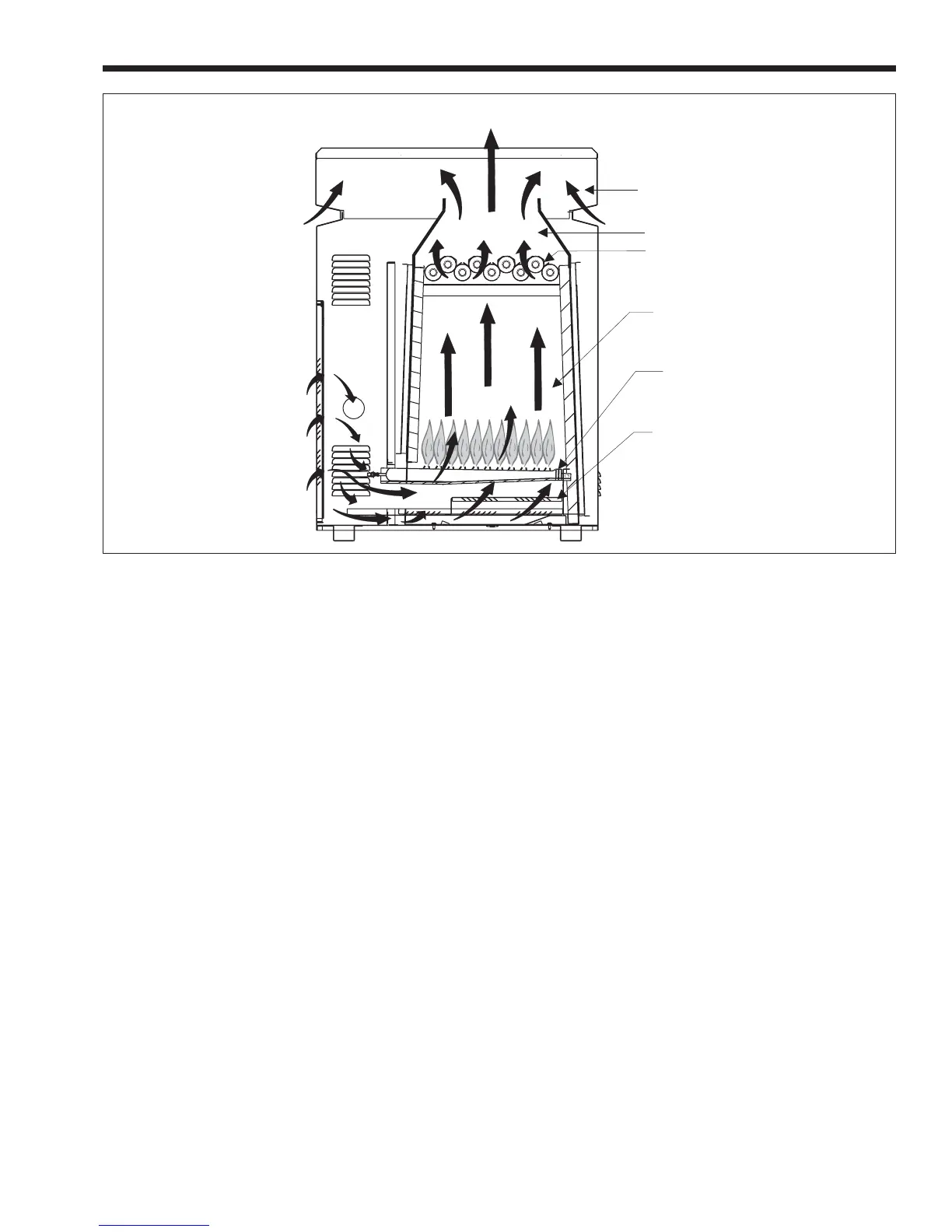

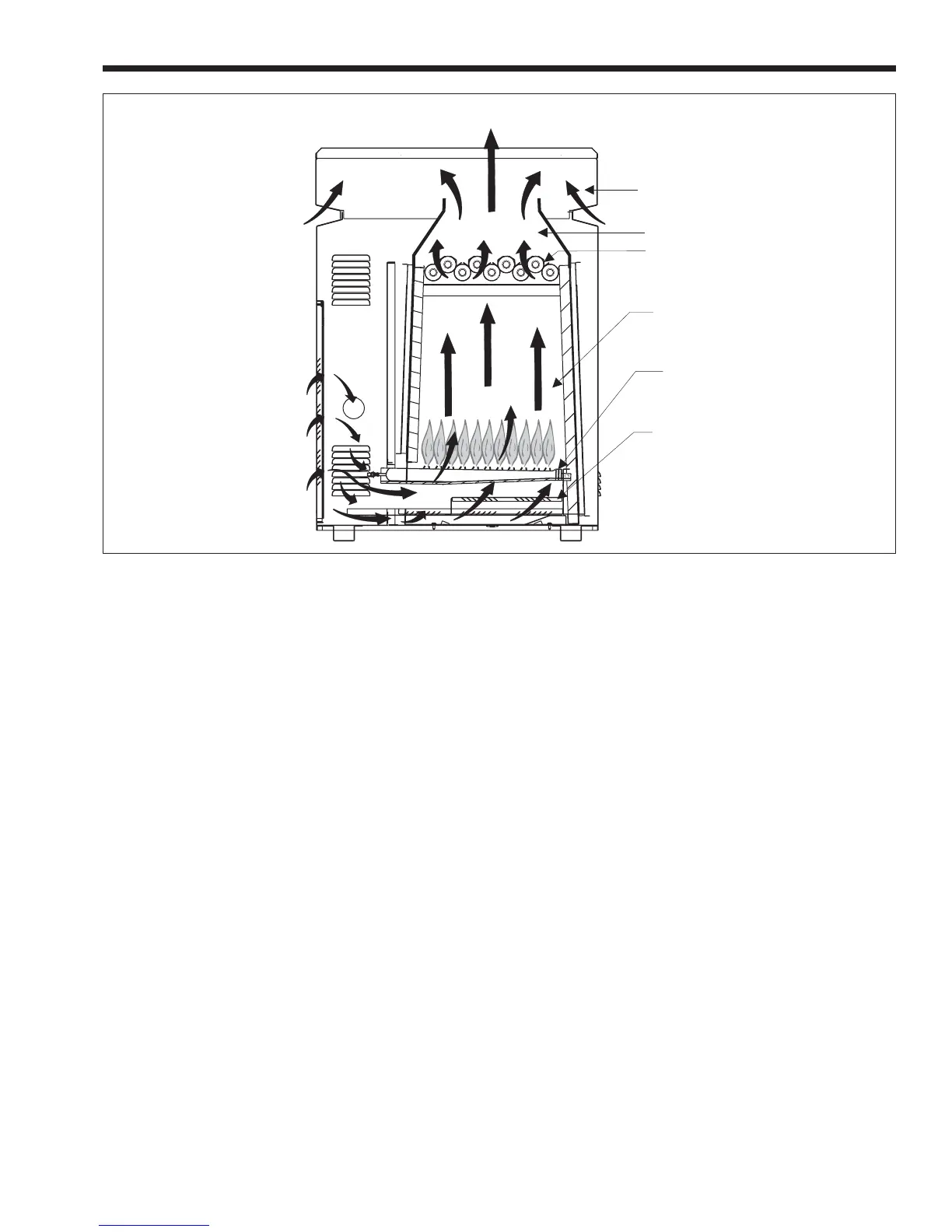

FLUE COLLECTOR

HEAT EXCHANGER

COMBUSTION CHAMBER

BURNER

BURNER TRAY SHELF

VENT TOP

EXHAUST

AIR

FLOW

Figure 26. Atmospheric Combustion System

Loading...

Loading...