LXi

™

Pool/Spa Heater Installation and Operation Manual Page 37

ture from this reading. This difference

is the temperature rise. Refer to Table 7.

If your measured temperature rise is within the

range designated for your heater, skip steps

6 through 8.

6. Locate the bypass adjustment screw on the right-

hand side of the header. (See Figure 33.) Loosen

the nut so that the screw can be adjusted. A slight

water leak past the nut may be expected. Turn the

screw counterclockwise to decrease the tempera-

ture rise, and clockwise to increase the tempera-

ture rise as needed to achieve the ranges in

Table 7. After the adjustment, tighten the nut so

that no leaks occur.

7. If the temperature rise is too low and cannot be

raised by means of the adjustment screw, the fl ow

is in excess of 125 GPM (7.9 lps). An external

bypass will need to be installed, or if one already

exists, open the external bypass valve gradu-

ally until the temperature range in Table 7 is

achieved.

8. If it was necessary to adjust the external bypass

as outlined in step 7, scribe a line on the bypass

shaft and case to mark the correct adjustment

position. Wire or remove the valve handle to

prevent tampering.

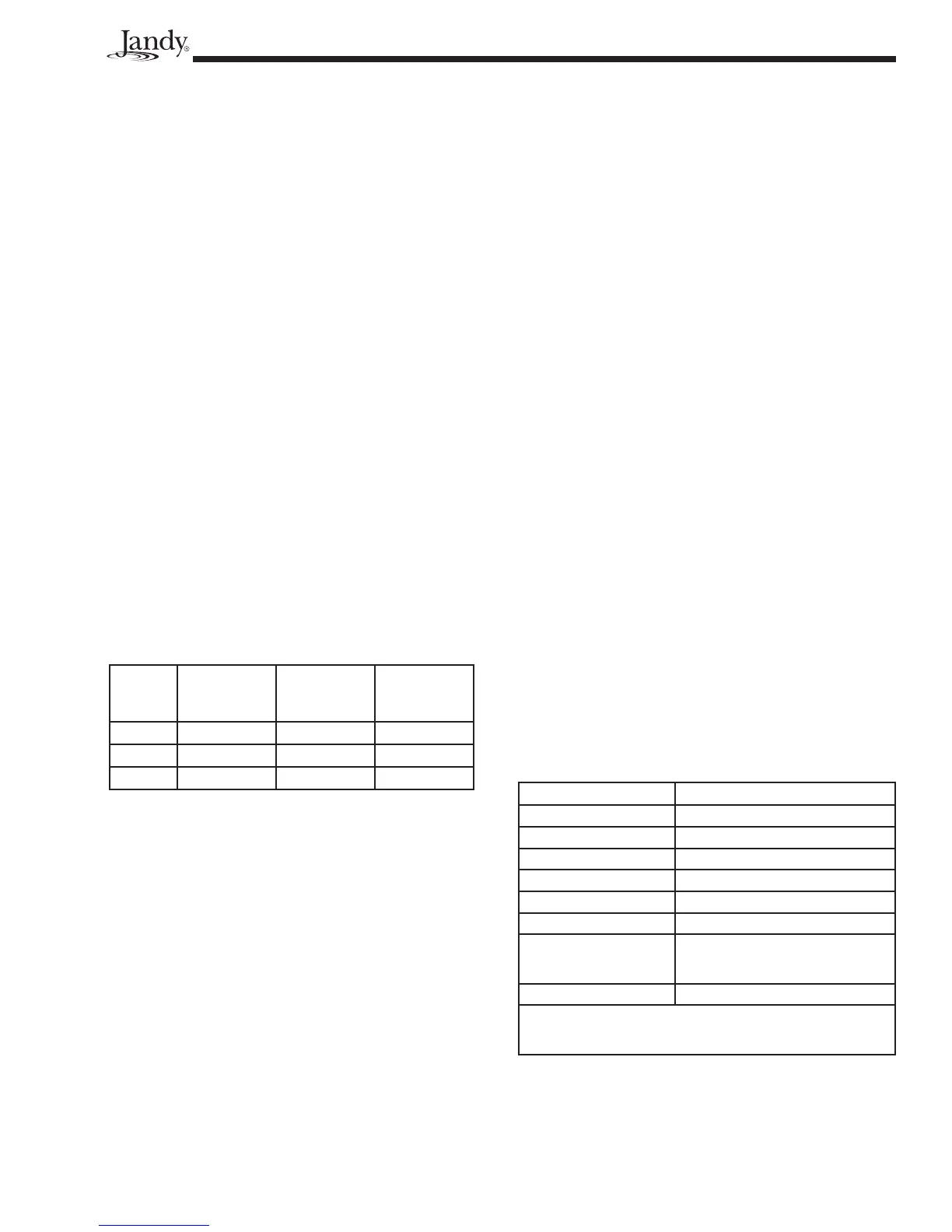

Table 7. Water Temperature Rise and Flow Rates

(Measured at Return Header)

Model

Minimum

Temp Rise,

°F (°C)

Maximum

Temp Rise,

°F (°C)

Minimum

System Flow

GPM (lps)

250 7 (4) 10 (6) 30 (1.9)

300 8 (4) 11 (6) 30 (1.9)

400 13 (7) 17 (9) 30 (1.9)

In a system without external bypass, it may be

necessary to make changes. If temperature rise is too

low, a manual bypass must be installed. If tempera-

ture rise is too high, there is inadequate fl ow, possibly

requiring a change to the piping system or a larger

pump. Before proceeding with either remedy, verify

proper heater operation. Low gas input results in low

temperature rise and vice-versa. A problem with the

heater internal bypass assembly also affects measured

temperature rise.

7.9 Burner Throat Pressure Adjustment

The burner throat pressure should be adjusted

using the air orifi ce on the intake of the fan. This air

orifi ce has a slider attached to it. This slider is used to

increase or decrease air pressure. The air pressure will

drop as more of the slider covers the air orifi ce. The

air pressure will increase as more of the air orifi ce is

exposed. The pressure should be adjusted to 1.0" WC.

See Section 10.4.

Section 8. Maintenance

8.1 Water Chemistry

The mineral content of swimming pool water

increases daily due to natural evaporation and the addi-

tion of sanitizing chemicals. If the mineral concentra-

tion in the pool gets too high, the excess minerals will

deposit on the walls of the pool, in the fi lter system,

and in the heater tubes.

The proper chemical balance in spa water is more

critical than in a swimming pool heater operation. Due

to the spa’s size, high water temperature and heavy

usage, chemical values in a spa can vary greatly. This

chemical imbalance can result in unsanitary water

conditions, and affect the life of the heater.

Proper chemical balances are necessary for

sanitary bathing conditions as well as ensuring your

heater's long life. Kits are available from your local

pool supply dealer for making the various tests for

mineral content. One of these kits will detect copper

in the system. This is usually a warning that corrosion

is taking place, possibly due to a low pH value com-

bined with other chemistry problems. The condition

can be corrected by changing the spa water and closely

monitoring the pH factor and chemical properties of

the water. Be sure to keep your chemical levels within

the values indicated in Table 8. Jandy Pool Products,

Inc. does not warrant heat exchangers damaged by

corrosive chemical levels or excess dissolved solids

in pool or spa water.

For spas, it is also necessary to perform water

changes in addition to chemical treatment. It is recom-

mended to change the spa water every 60 days for light

usage and every 30 days if usage is heavy.

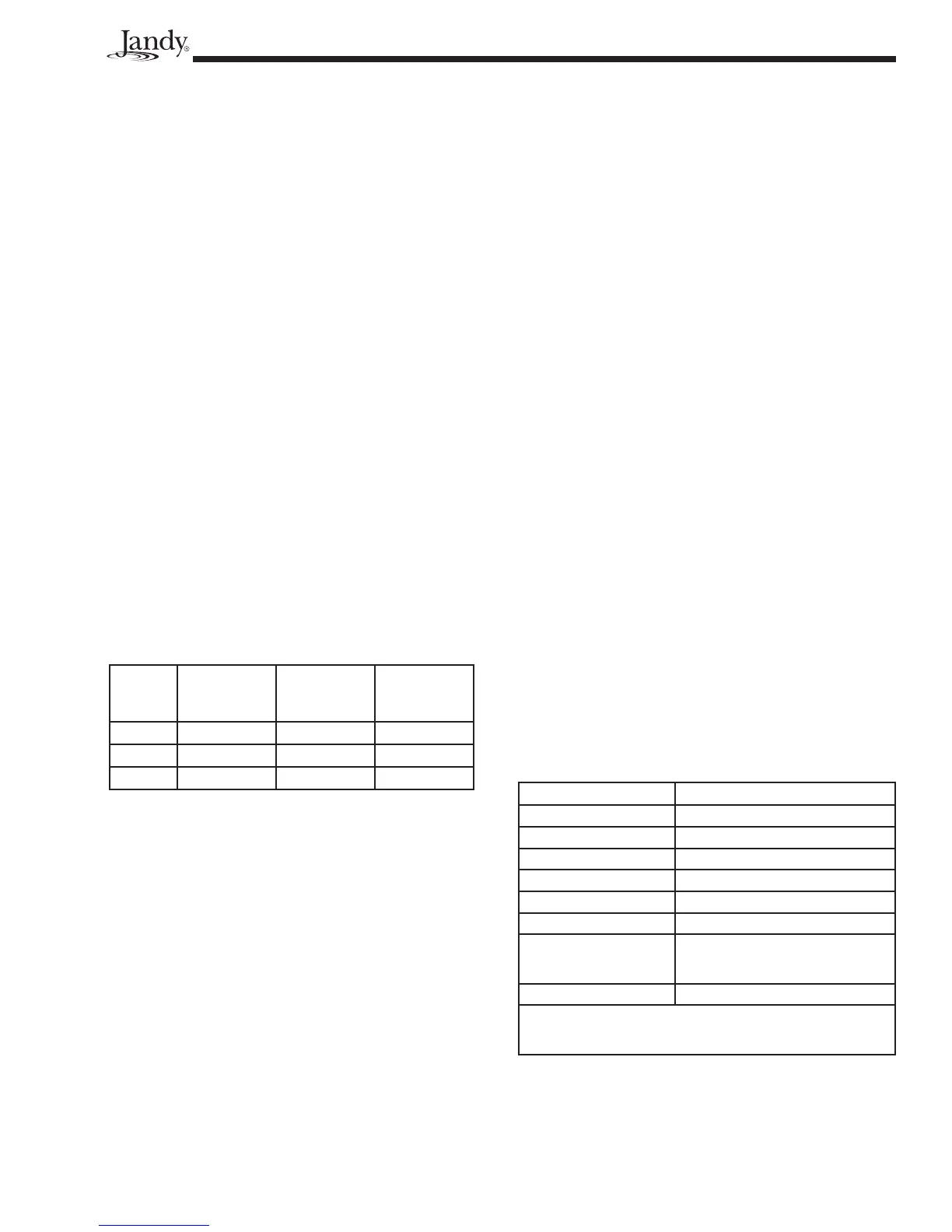

Table 8. Optimal Water Chemistry Ranges*

Test Recommended Level

Free Chlorine 1.0 to 3.0 ppm

Bromine 2.0 to 4.0 ppm

pH 7.2 to 7.8 (Ideal range is 7.4 to 7.6)

Total Alkalinity (TA) 80 to 120 ppm

Calcium Hardness (CH) 175 to 400 ppm

Cyanuric Acid 50 to 75 ppm

Total Dissolved Solids

(TDS)

1000 to 2000 ppm (Excluding dis-

solved NaCl from a Salt Chlorine

Generator)

Copper 0 ppm

* Concentration levels taken from Basic Pool and Spa

Technology published by APSP (Association of Pool and Spa

Professionals).

Loading...

Loading...